Device and method for measuring micro-pore size based on fiber Bragg grating

A fiber optic Bragg and measurement device technology, applied in the direction of measurement devices, optical devices, instruments, etc., can solve the problems of difficult to achieve precise online measurement, two-dimensional measurement error, inseparability, etc., to meet industrial high-speed measurement and improve adaptability Ability, data processing simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Below in conjunction with accompanying drawing, specific embodiment of the present invention is described in further detail:

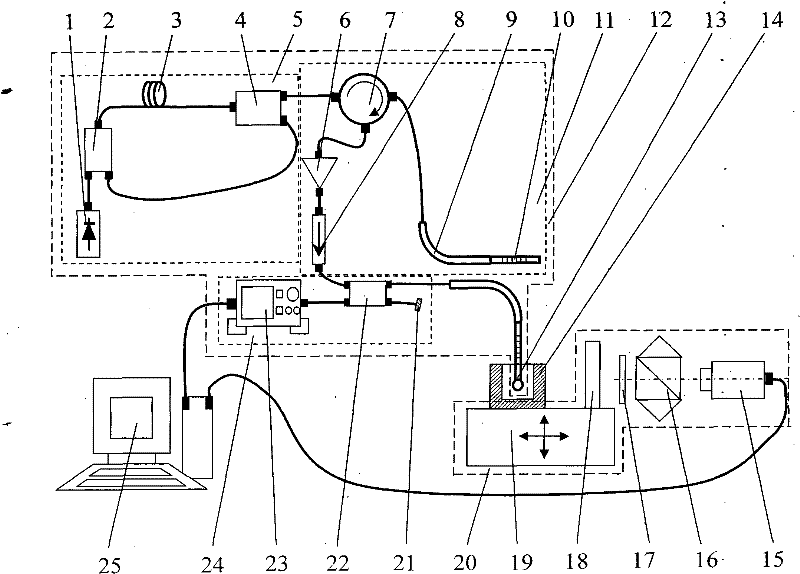

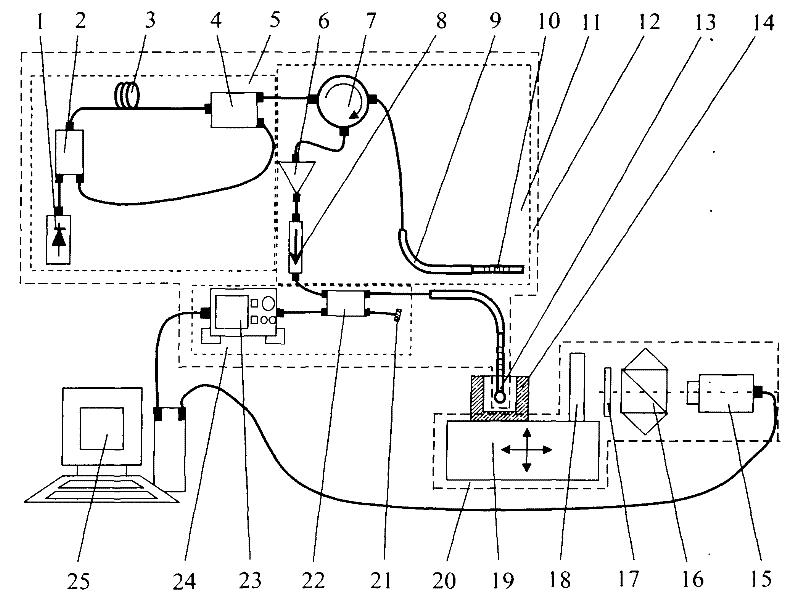

[0028] A kind of micropore size measuring device based on fiber Bragg gratings includes aiming and signaling device 12, length measuring device 20 and computer 25; aiming and signaling device 12 is composed of broadband light source system 5, temperature compensation system 11, probe 13 and signal Receiving system 24 forms; Described broadband light source system 5 comprises pumping laser 1, WDM coupler 2, erbium-doped optical fiber 3 and beam splitter 4, and the two ends of erbium-doped optical fiber 3 are connected with WDM coupler 2 and beam splitter respectively 4 connection, the optical fiber respectively communicates the pump laser 1 with the WDM coupler 2, and the WDM coupler 2 and the beam splitter 4; the signal receiving system 24 is composed of a spectrum analyzer 23, a fiber coupler 22 and a refractive index matching liquid 21, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com