Tip clearance measurement method based on all-fiber tip timing

A technology of blade tip timing and blade tip clearance, which is used in measuring devices, optical devices, instruments, etc., to achieve the effects of strong anti-electromagnetic interference ability, improved clearance measurement accuracy, and fast dynamic response speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to make the objectives, technical solutions, and advantages of the present invention clearer, the following further describes the embodiments of the present invention in detail.

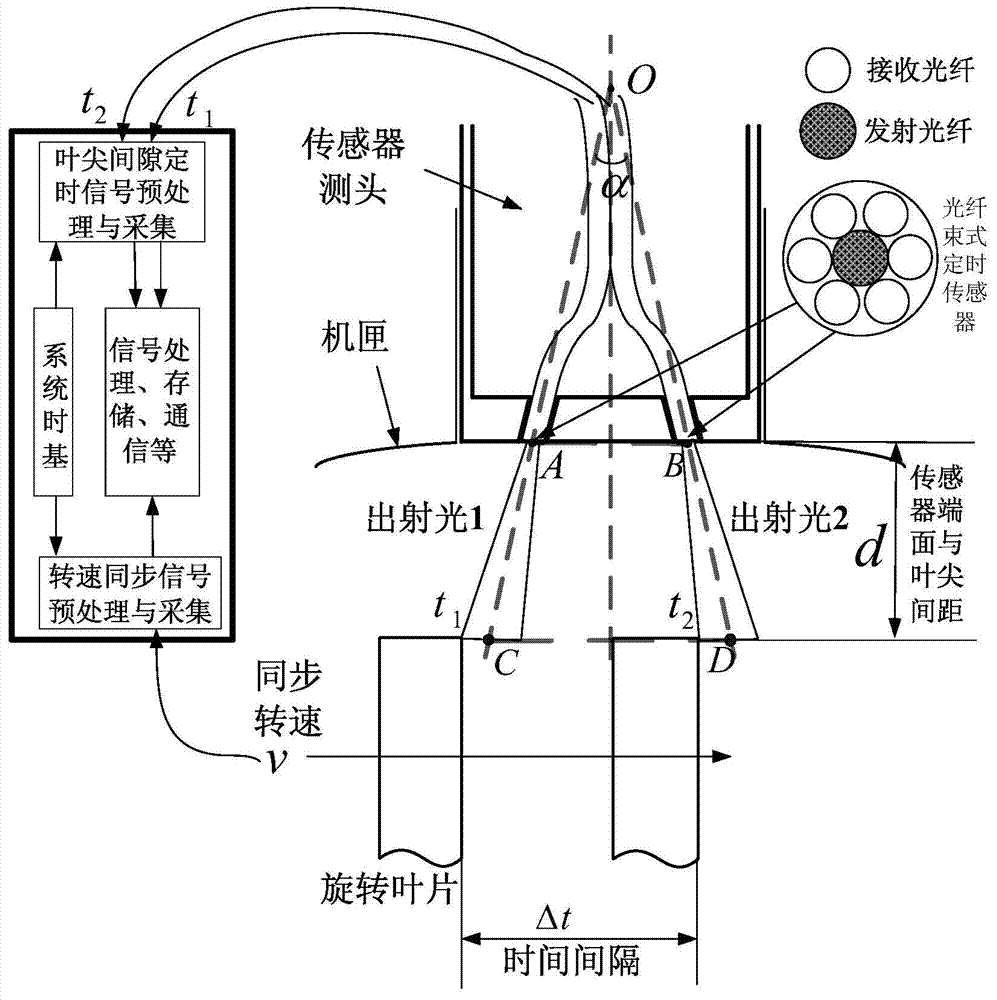

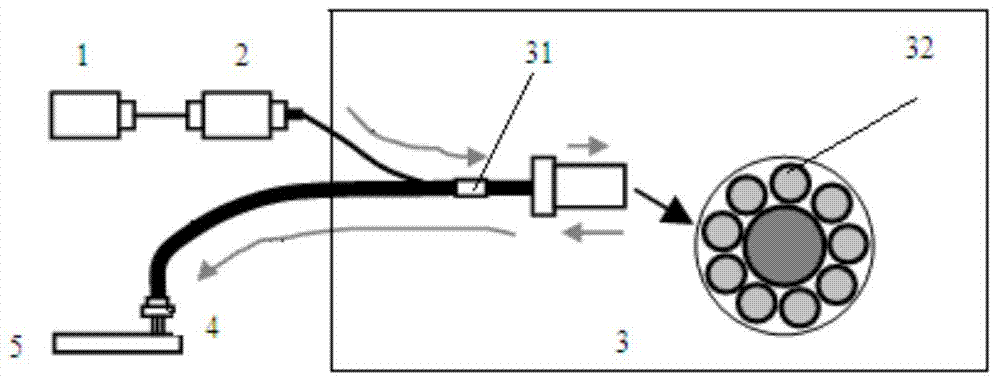

[0028] The laser triangulation method is suitable for short-range high-precision measurement. The basic principle is to place the light source, the surface of the measured object and the receiving system at three points to form a triangular light path, and then calculate the measured object based on the mathematical relationship between similar triangles Small displacement of the surface of the object. Among them, the single-point laser triangulation method can be divided into two types: the direct type and the oblique type according to the incident mode of the light source.

[0029] The principle of the direct laser triangulation method is: after the laser is focused by the transmitting lens, it is incident perpendicularly to the surface of the object to be measured; when the object to be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com