Automatic welding system of hub small parts

An automatic welding and wheel hub technology, which is applied in welding equipment, welding equipment, auxiliary welding equipment, etc., can solve the problems that affect the welding accuracy of small parts to be welded, the relative position is not completely consistent, and the positioning error of small wheel hub parts, etc., to improve welding Efficiency, avoiding secondary positioning error, and eliminating the effect of secondary positioning error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

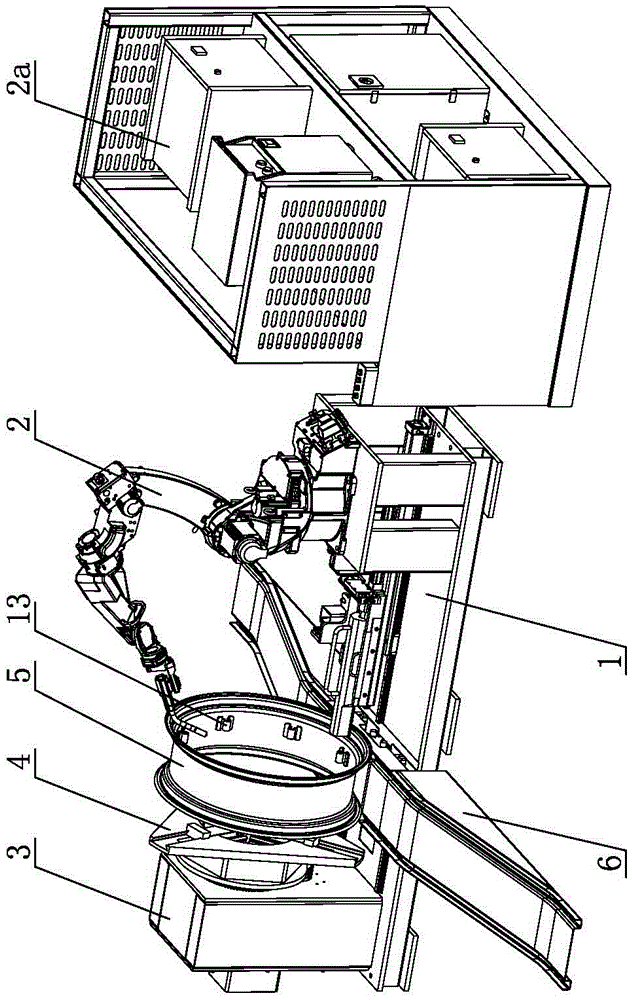

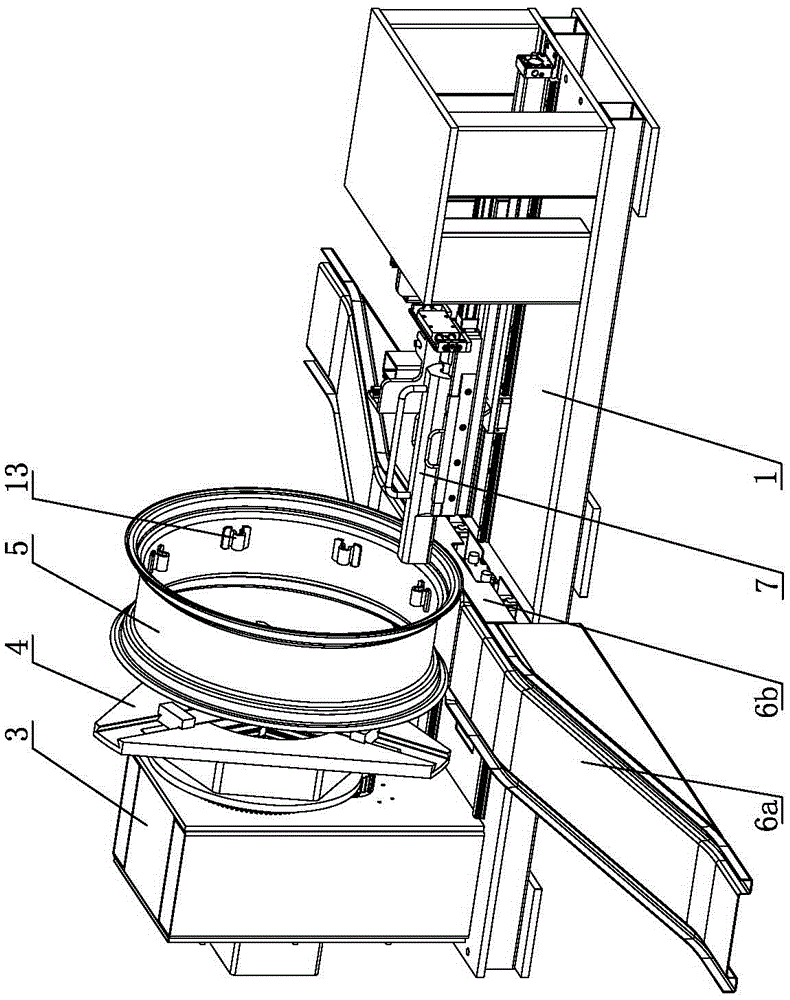

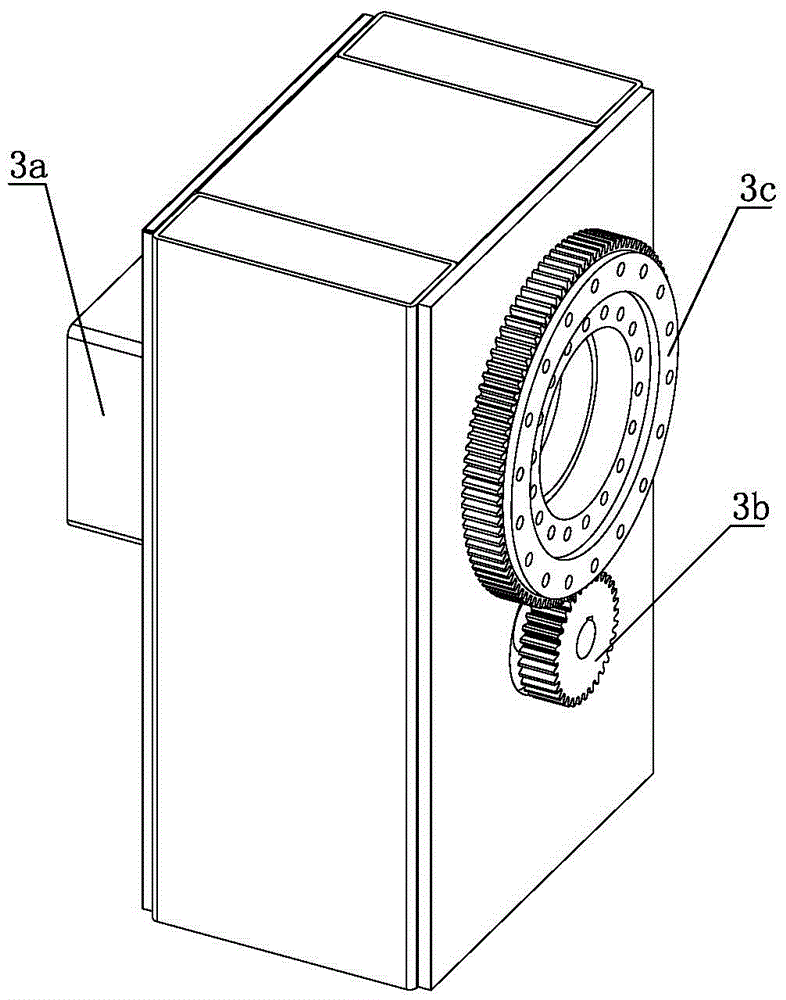

[0024] Such as Figure 1-10 , Is an automatic welding system for small wheel hubs, including a base 1 installed with a welding robot 2. The welding robot 2 is controlled by a robot control system 2a, and a welding slewing mechanism 3 is provided on the pedestal 1. The welding slewing mechanism 3 includes a servo motor 3a, The output shaft of the servo motor 3a is connected with a driving gear 3b for transmission, the driving gear 3b meshes with the driven gear 3c, and the driven gear 3c has a number of flange connection holes evenly distributed in the circumferential direction; the welding slewing mechanism 3 and clamping the wheel hub 5 to be welded The floating centering clamping mechanism 4 is connected in transmission; the floating centering clamping mechanism 4 includes a mounting base plate 4a which is connected to the driven gear 3c via a flange. At least three radial sliding grooves are evenly distributed on the mounting base plate 4a. A sliding jaw 4b driven by an air ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com