Curve welding seam welding technology based on line structured light

A line-structured light and curve technology, which is applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve problems that cannot meet welding quality and requirements, and achieve high robustness, real-time performance, accurate positioning, The effect of high welding precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

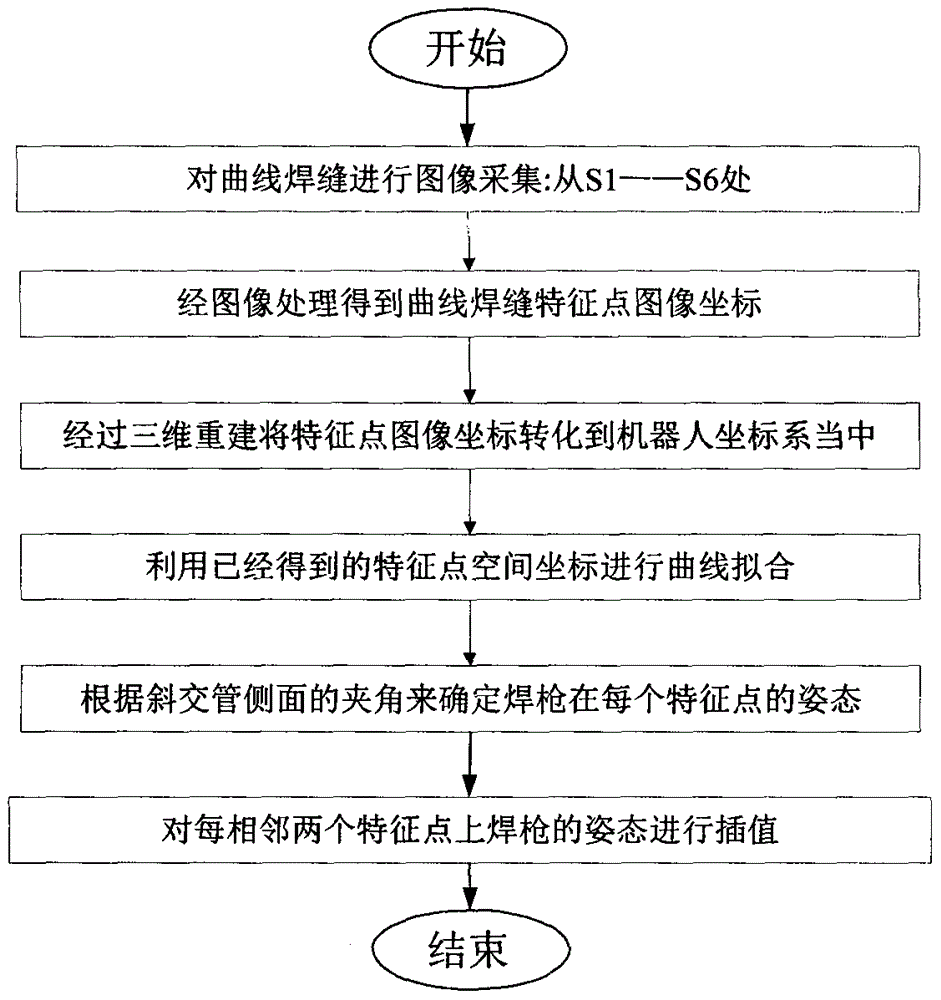

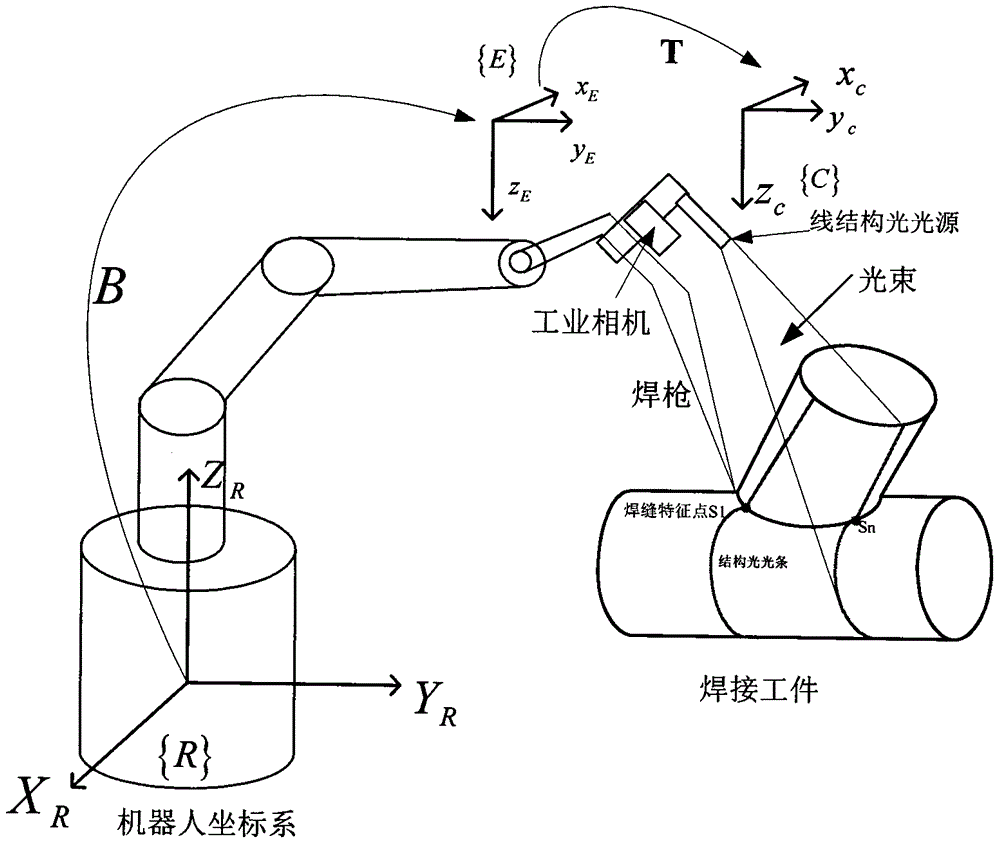

[0026] Such as figure 1 Shown is a flow chart of the automatic welding technology for curved seams facing oblique pipes based on line structured light. The implementation of the present invention will be further described below according to the drawings and specific examples:

[0027] Step 1: Adjust the six-degree-of-freedom industrial robot to drive the industrial camera and the line structured light sensor on the end of the machine, so that the structured light band illuminates the position S 1 At , use an industrial camera to take pictures of the light band on the curved weld seam, and keep taking pictures until S n At , 6 images are taken in the demonstration, that is, S 6 place. And the captured digital image is transmitted to the image processor.

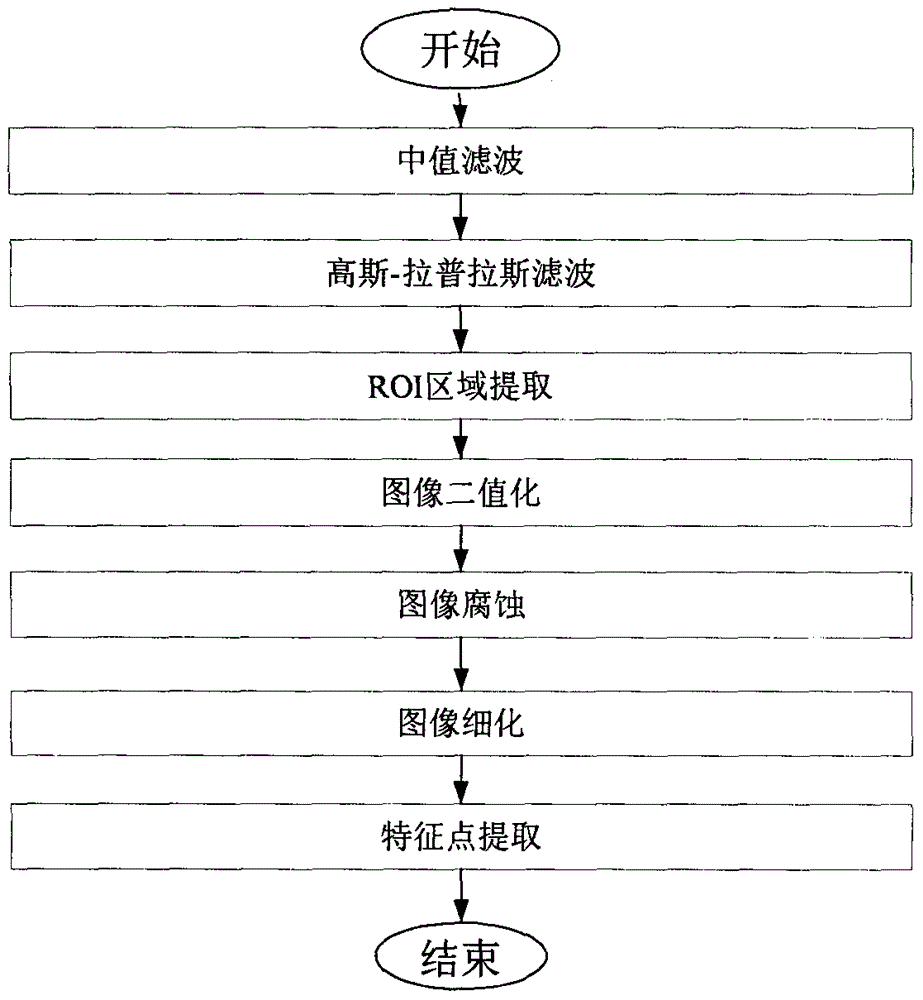

[0028] Step 2: Perform image processing on the captured curve weld image, the specific process is as follows:

[0029] Step 2-1, filter the image:

[0030] Step 2-1-1, Median filtering: select a 3*3 filtering template to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com