Automatic welder of wheel buckle type scaffold vertical rods

An automatic welding machine and scaffolding technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of high labor intensity and uneven welding, and achieve reduced labor intensity, high welding precision and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The specific embodiment of the present invention will be described in detail below in conjunction with the accompanying drawings.

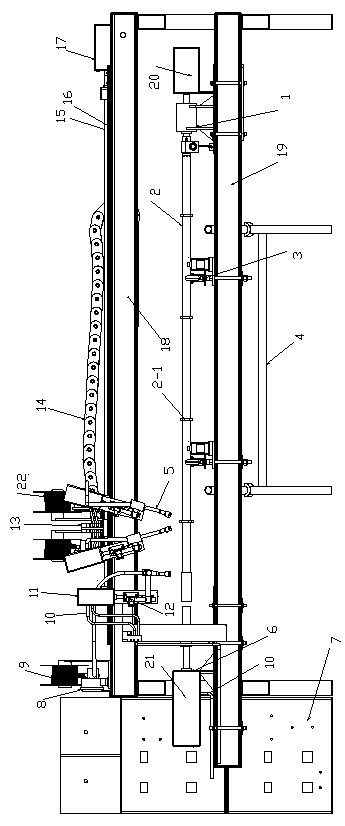

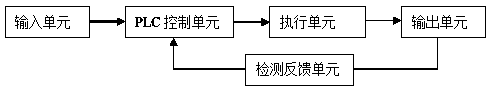

[0018] Such as figure 1 As shown, the automatic welding machine for the vertical pole of the wheel buckle scaffolding includes a support and a control cabinet 7, and the support includes a support upper part 18 and a support lower part 19. The upper part 18 of the bracket is provided with a pneumatic cylinder 11, a welding torch adjustment mechanism 12, a solenoid valve 13, a welding torch 5, a wire feeder 8, a welding wire reel 9, a ball screw 15, a stepper motor 17, a linear guide rail 16 and a drag chain 14. The support lower part 19 is provided with an electric support assembly 1, a pneumatic clamping assembly 2 and a steel pipe support assembly 3.

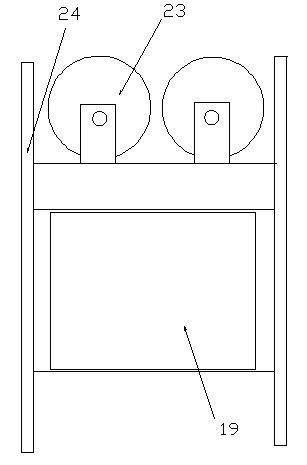

[0019] The lower part 19 of the support is a working platform, wherein the electric support assembly 1 is provided with a rotating motor 20, which can rotate the steel pipe 2 by 180 degree...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com