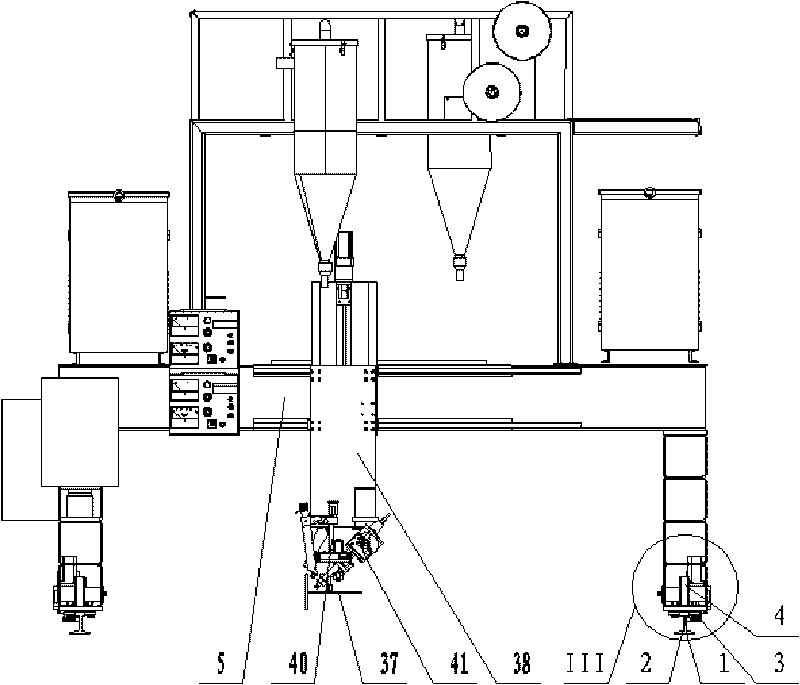

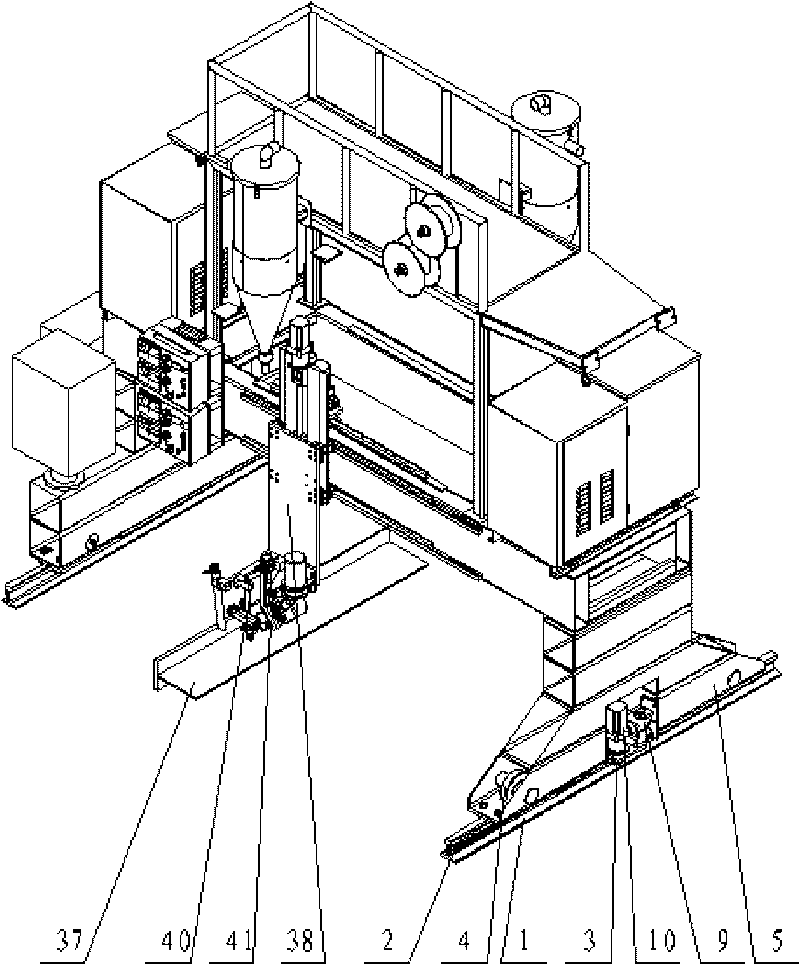

Profiling device and numerical-control gate-type stringer welding machine using same

A profiling device, welding machine technology, applied in auxiliary devices, welding equipment, welding equipment and other directions, can solve the problems of low welding accuracy, reduced welding accuracy, decreased reaction sensitivity, etc., and achieves simple and convenient use, improved welding accuracy, manufacturing low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

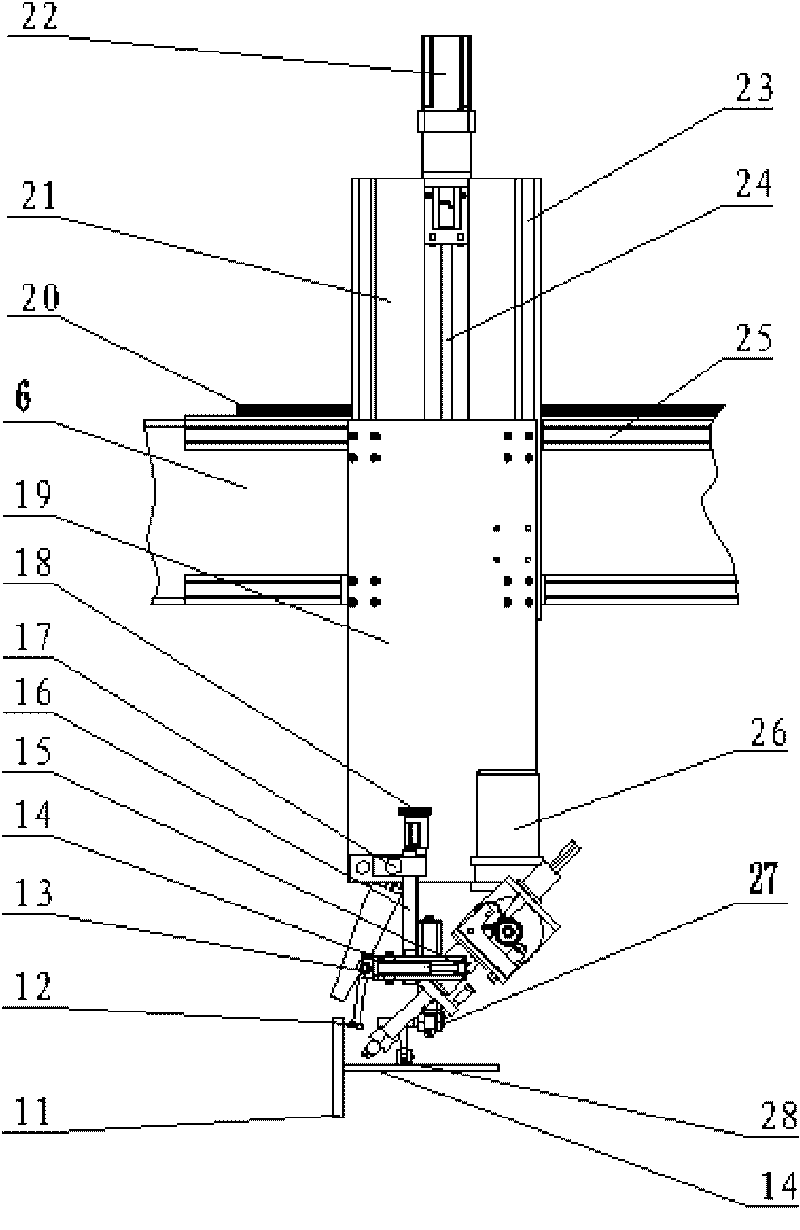

[0009] The profiling device of the present invention comprises a housing, on which a rotating shaft is installed, on which a contact and a rocker are installed, on which a reset device is installed, the reset device is connected to the housing, and two sensors are installed on the housing, The free end of the rocker is located between the two sensors. When installing, install the profiling device near the welding torch of the portal welder. When in use, the rocker is brought into contact with the workpiece to be welded, so that the rocker can swing with the change of the shape of the workpiece to be welded, so that the rocker drives the contact to swing between the two sensors, and when the contact is close to any sensor , the sensor can respectively send signals to the control device, and the control device controls the movement of the welding torch to realize the tracking of the welding seam by the welding torch.

[0010] Such as Figure 9 As shown, the reset device is com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com