Automatic welding device for rotary tillage cutter shaft

A technology of automatic welding and rotary tiller, applied in the direction of auxiliary equipment, welding equipment, auxiliary welding equipment, etc., can solve the problems of increased maintenance cost, unfavorable operator's grasp, cumbersome operation, etc., so as to improve welding quality and facilitate popularization and use , the effect of simple overall structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

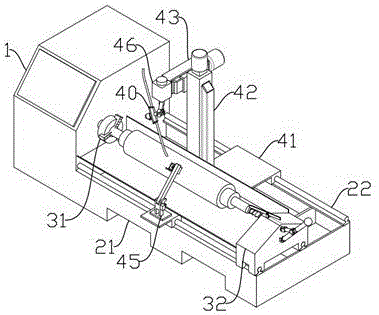

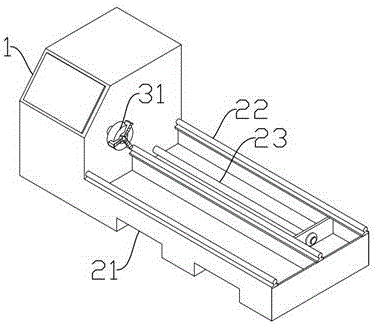

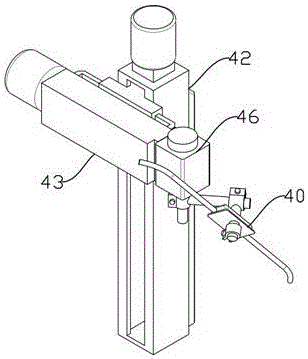

[0035] like Figure 1-8 As shown, the automatic welding device for the rotary tiller shaft includes a numerical control part 1, a base part connected to the numerical control part 1, and a fixed part and a welding torch part arranged on the upper part of the base part;

[0036] The numerical control part 1 includes a numerical control system and a transmission mechanism connected to the numerical control system, and the transmission mechanism includes a numerical control stepping motor and a first-stage worm gear reduction device;

[0037] The base part includes a base housing 21, and sliding rails 22 and ball screws 23 respectively arranged on the upper and middle parts of the base housing 21; the sliding rails 22 include three mutually parallel Ω-shaped rails, three Ω The type track is fixed on the upper part of the base housing 21 through a screw; one end of the ball screw 23 is connected to the transmission mechanism, and the other end is fixed on the base housing 21 throu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com