Power battery ultrasonic welding equipment

An ultrasonic welding and power battery technology, which is applied in welding equipment, non-electric welding equipment, metal processing equipment, etc., can solve the problems of low welding precision and good product rate, high production cost and failure rate, and low welding automation procedures, and achieve the goal of welding Improve efficiency and welding precision, high degree of automation, reduce production cost and failure rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The following examples are further explanations and supplements to the present invention, and will not constitute any limitation to the present invention.

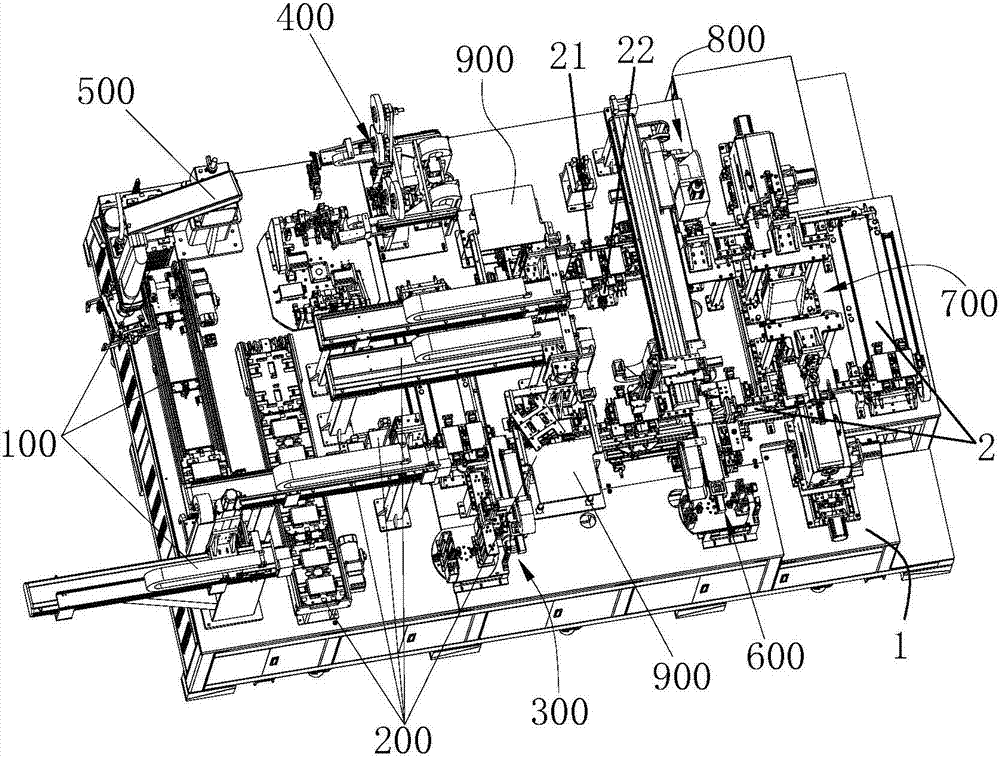

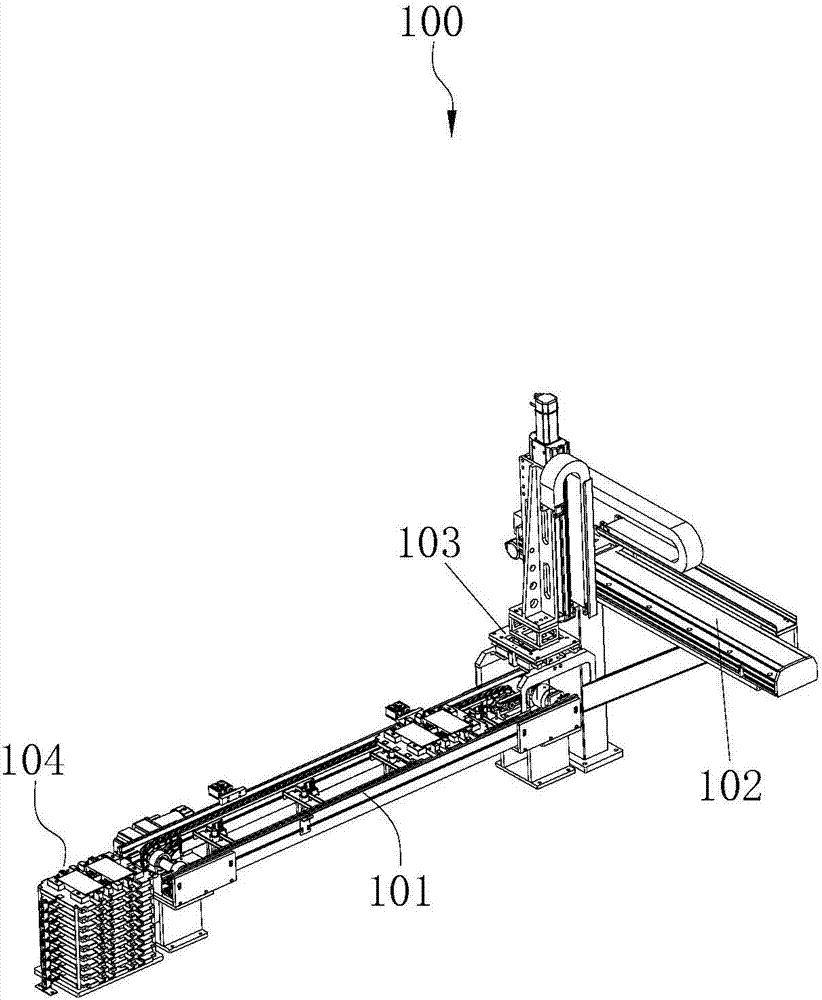

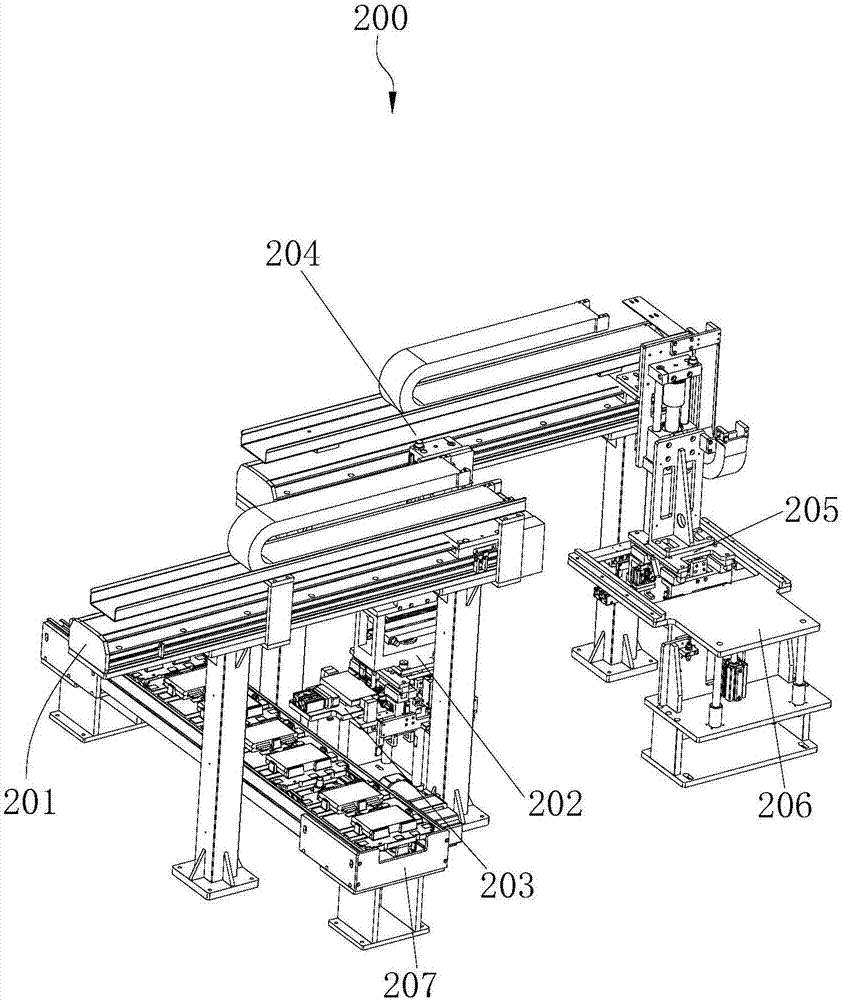

[0042] Such as Figure 1 to Figure 14 As shown, the power battery ultrasonic welding equipment of the present invention includes: a workbench 1, a feeding assembly line, a discharging assembly line, a tray feeding assembly 100, a cell feeding assembly 200, a connecting piece feeding assembly 300, a film assembly 400, an electrical Core blanking assembly 500 , reflow line body 2 , multiple clamps 21 , clamp positioning assembly 22 , protective sheet loading assembly 600 , ultrasonic welding assembly 700 , resistance welding assembly 800 and platen pick-and-place assembly 900 . Wherein, the feed line and the discharge line (not shown in the figure) are respectively set at the inlet and outlet of the workbench 1 (not shown in the figure), the tray loading assembly 100, the cell loading Component 200, connecting sheet ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com