Vector-relation-based method for calibrating single-line laser radar and CCD camera

A single-line laser radar and laser radar technology, applied in the field of computer vision, can solve the problems of low calibration accuracy and complicated calibration process, and achieve the effects of ensuring calibration accuracy, simplifying calibration algorithm, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

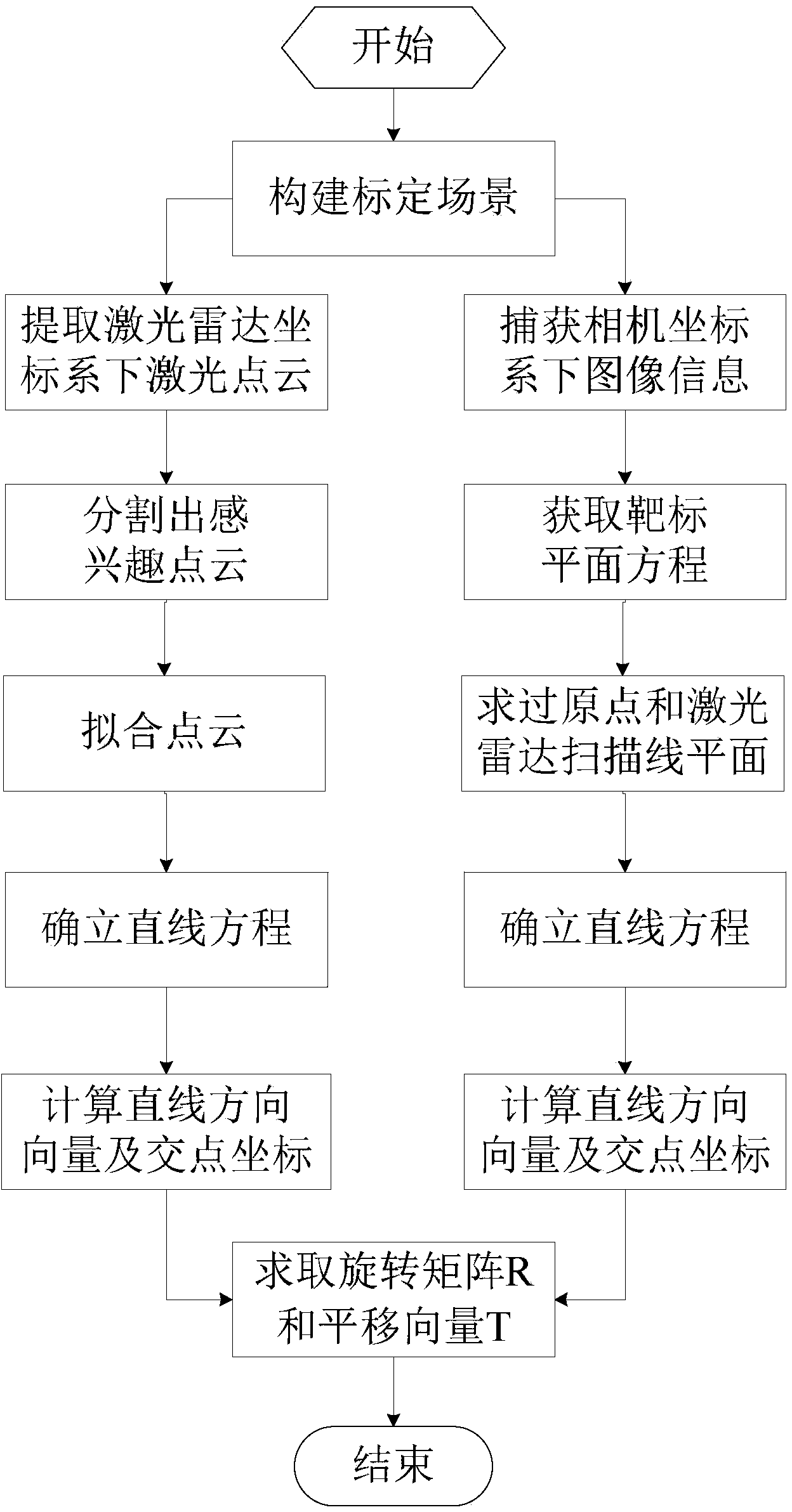

[0038] The flow chart of the single-line lidar and CCD camera calibration method based on the vector relationship is attached figure 1 As shown, it specifically includes the following steps:

[0039] Step 1, build a calibration scene.

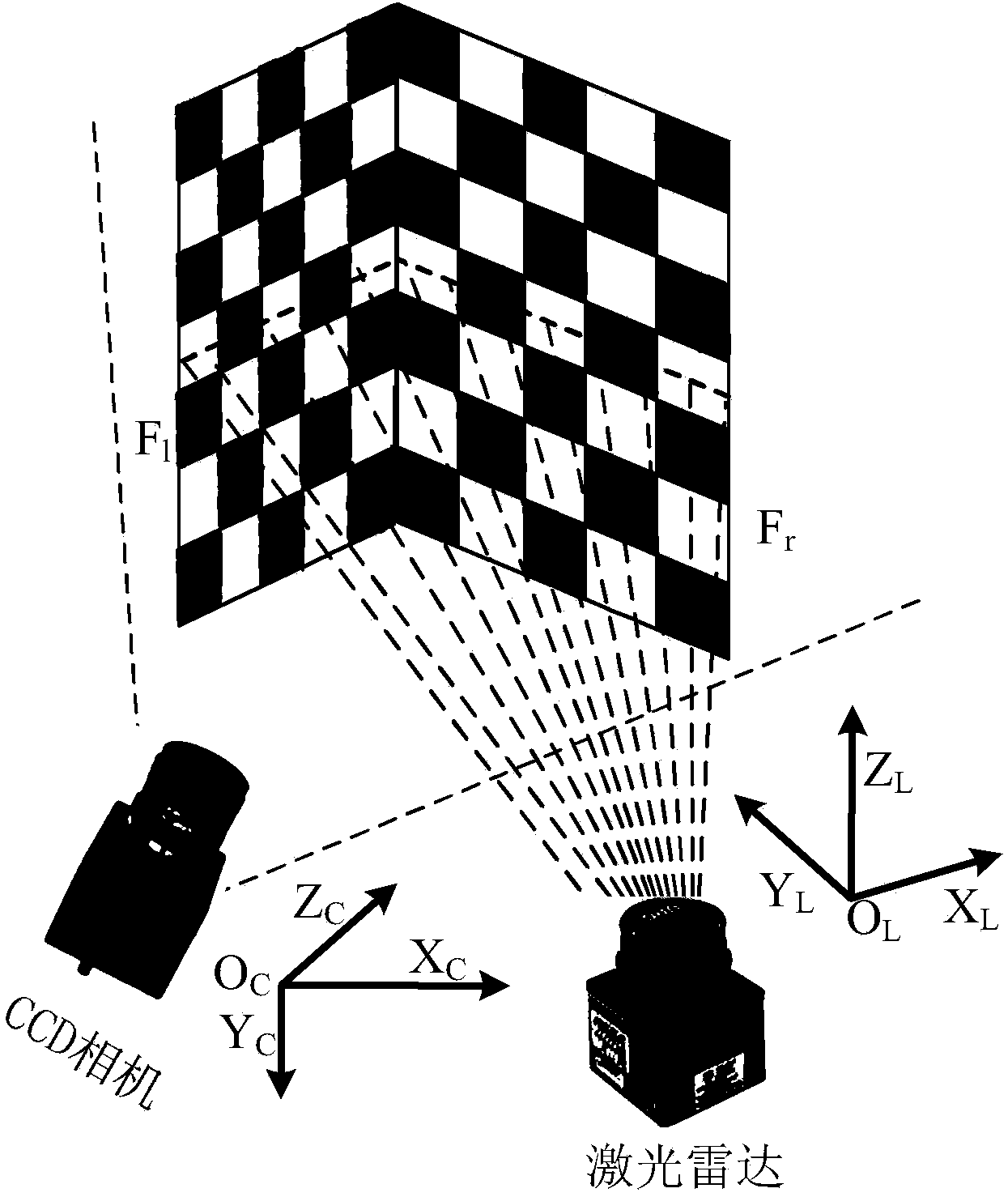

[0040] The present invention needs to figure 2 The laser and image data are extracted from the specific calibration scene shown, and the method of constructing the calibration scene is cheap and easy to implement. Specific steps are as follows:

[0041] Step 1.1, use a flat wooden board to make two checkerboard calibration boards of B2 size, and the distance between the checkerboards is 44mm.

[0042] Step 1.2, place the two calibration plates at an α angle (80°≤α≤150°) to form a V-shaped target, and the left and right planes of the target are respectively defined by F l and F r express.

[0043] Step 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com