Binocular vision sensor on-site calibration method and binocular vision sensor on-site calibration device in complicated environment

A binocular vision and on-site calibration technology, which is applied in the direction of measuring devices, optical devices, instruments, etc., to achieve the effects of flexible and adjustable directions, flexible structure, and improved calibration efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

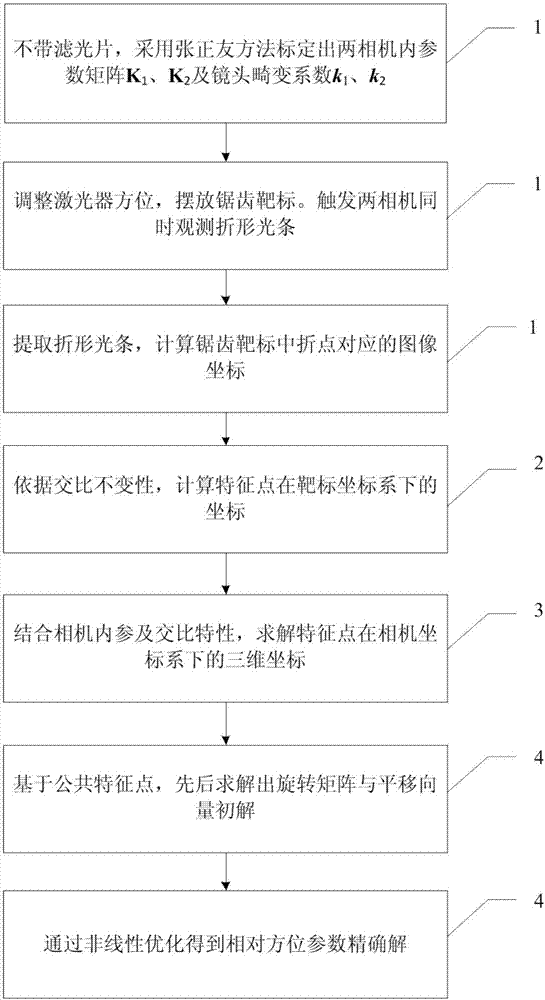

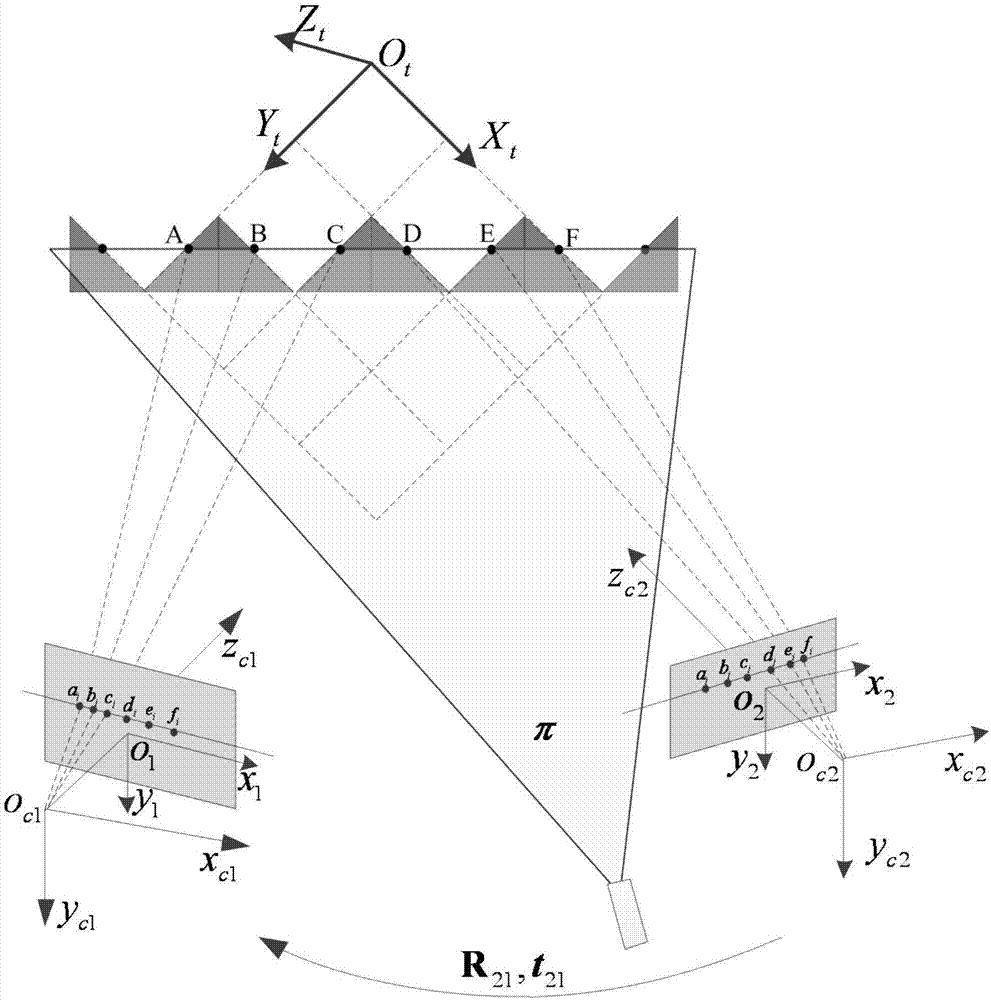

[0026] This method first uses the literature [3] (Zhang Z.A Flexible New Technique for CameraCalibration[J].IEEE Transactions on Pattern Analysis & Machine Intelligence, 2000,22(11):1330-1334.) to calibrate the internal parameters of the two cameras, and then extract the The laser and the sawtooth target form the image coordinates of the inflection points; at the same time, according to the image feature points, use the cross-ratio invariance to solve the coordinate values of the feature points in the target coordinate system; calculate the target according to the relationship between the spatial straight line direction and the image blanking point The three-dimensional coordinates of the feature points in each camera coordinate system; and then solve the relative external parameters of the two cameras, including the rotation matrix and transl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com