Sensor for detecting flux defect of wire rope

A defect detection and wire rope technology, applied in the field of sensors, can solve the problems of measurement deviation, large magnetic flux leakage, and difficulty in quantifying wire rope damage, and achieve the effect of automatic identification, simple and convenient installation, and improved accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

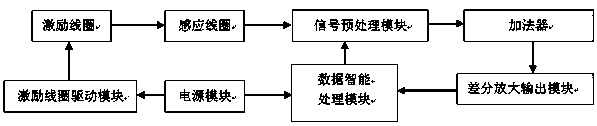

[0020] Such as figure 1 As shown, the present invention provides a steel wire rope magnetic flux defect detection sensor, its structure includes: data intelligent processing module, power supply module, excitation coil drive module, excitation coil, induction coil, signal preprocessing module, adder and differential amplification output module ; Among them, the excitation coil includes two sets of excitation coils composed of four semicircular coils, which can generate two magnetic fields of equal size and opposite directions; the induction coil is composed of four semicircular coils, when the defect of the steel wire rope passes through the induction coil , the induction coil generates an induced current.

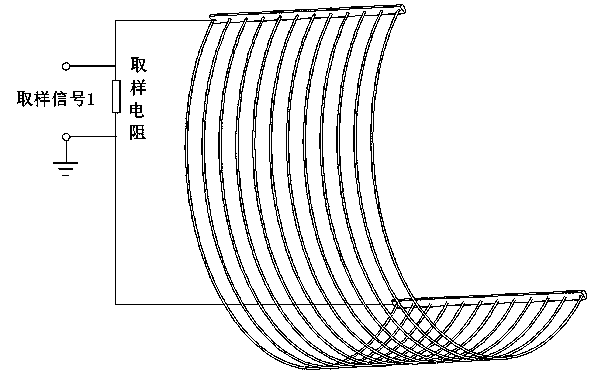

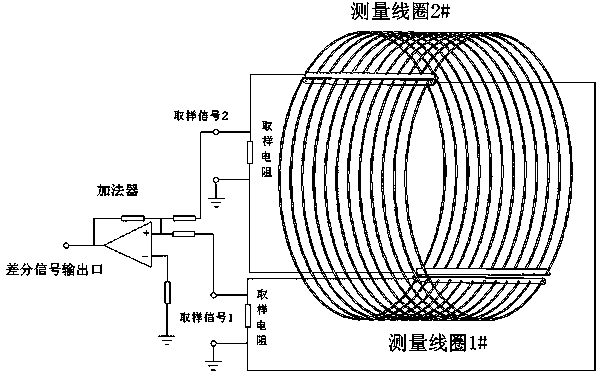

[0021] As shown in Figure 2, the two ends of each semicircular induction coil are connected to the two ends of the sampling resistor, and the induction current of the coil is converted into a voltage signal for measurement by measuring the sampling resistor.

[0022] Such...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com