Robust lens distortion correction method

A lens distortion and correction method technology, applied in the field of lens distortion correction and robust lens distortion correction, can solve the problems of difficult to solve the distortion coefficient, camera lens distortion, low practicability, etc. Model complex effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

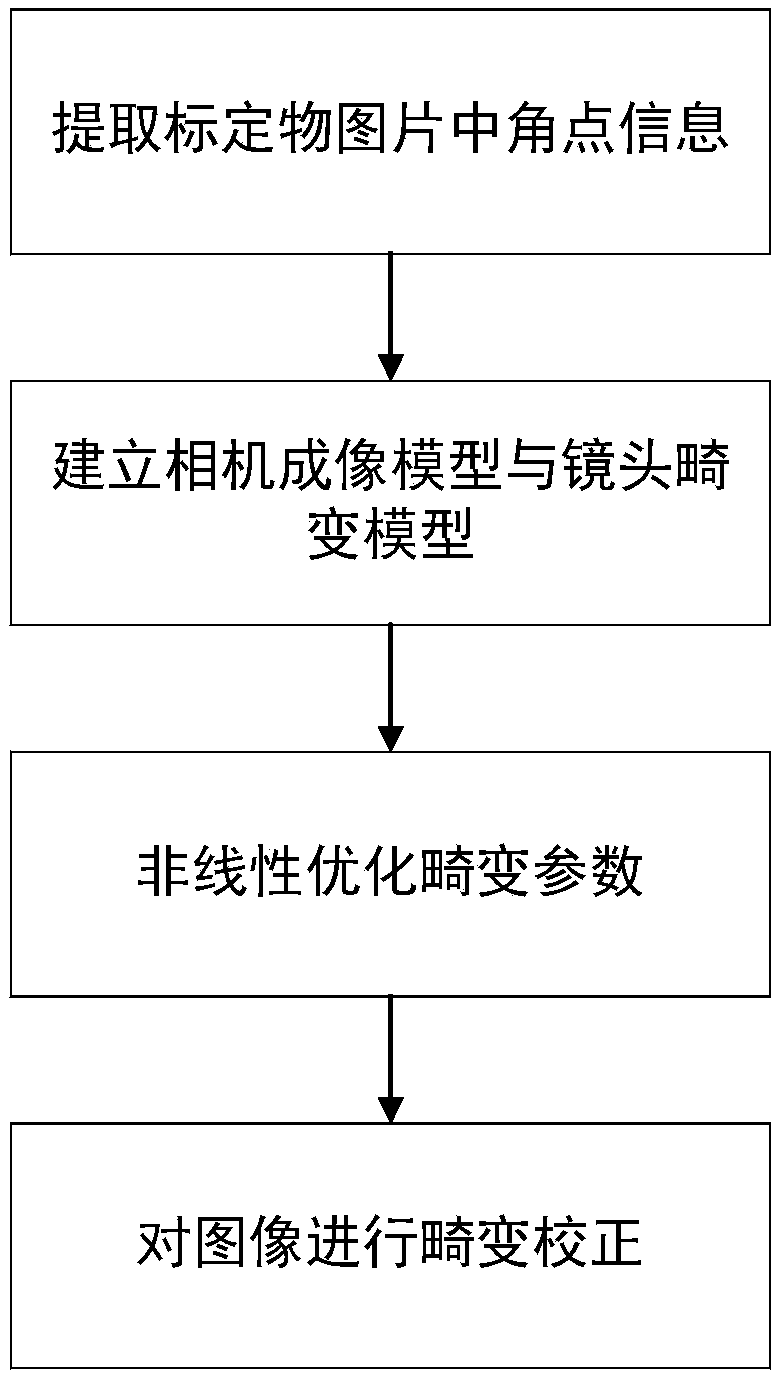

[0058] In order to solve the problem of coupling between internal and external parameters and lens distortion in the traditional camera calibration method, the present invention proposes a robust lens distortion correction method, the main process of which can be found in figure 1 , the solution of the present invention is illustrated below through specific examples.

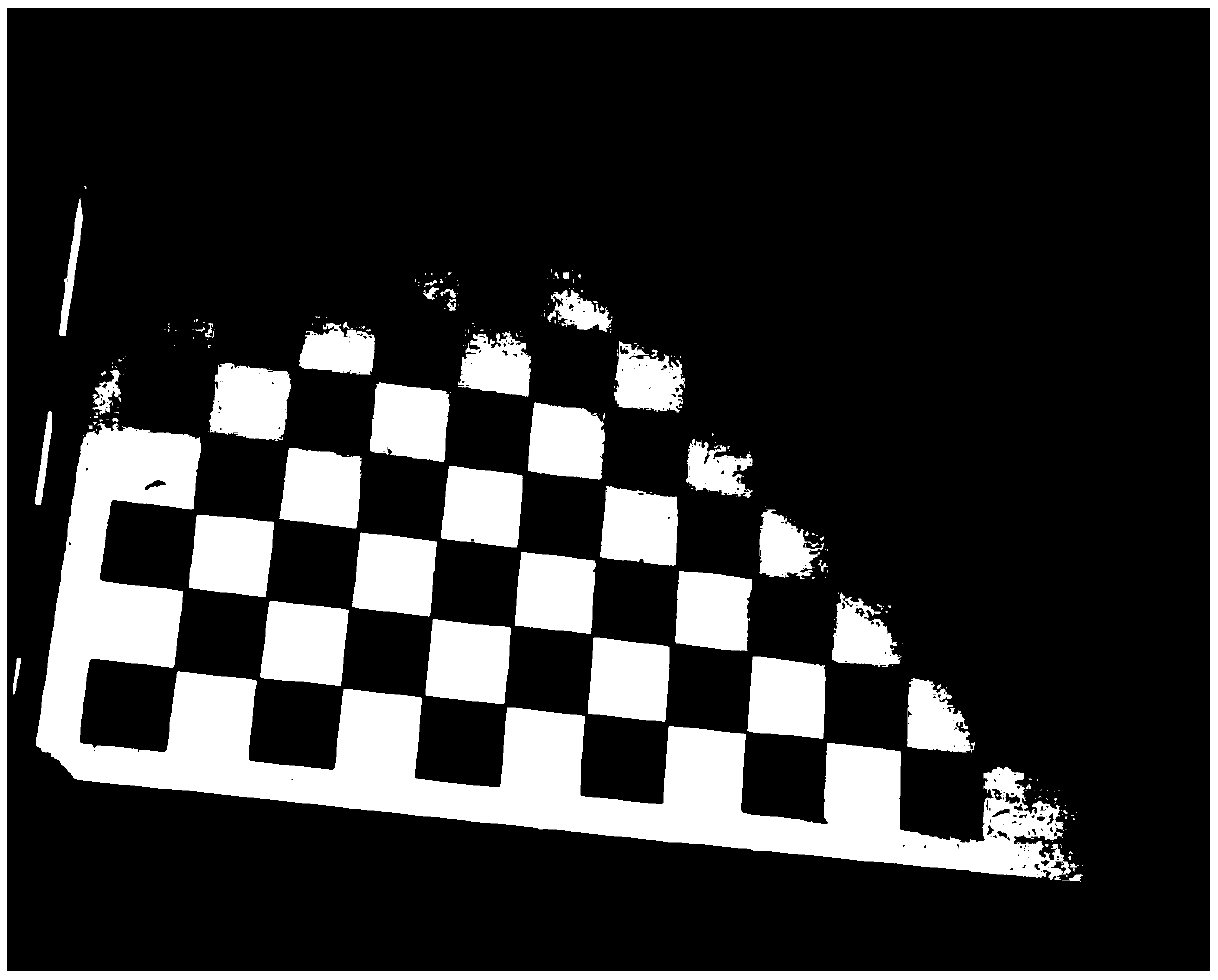

[0059] 1) First, use the checkerboard as the calibration object, attach the pre-printed calibration paper on a flat surface, and take pictures with a camera that needs distortion correction to ensure that the calibration checkerboard fills the field of view as much as possible. The pictures taken by the camera are as follows: figure 2 As shown in , the checkerboard corner points with sub-pixel level accuracy are extracted as the basis for correction;

[0060] The checkerboard is a widely used calibration object in the classical camera calibration method. The collinear and coplanar features of the corner points ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com