Lower ventilating method and apparatus for low-temperature grain storage film in bungalow barn

A ventilation method and the technology of flat warehouses, which are applied in the field of grain storage, can solve problems such as condensation in grain piles, damage to cold cores, waste of natural resources, etc., and achieve the requirements of reducing cooling capacity and fan power, saving energy, and saving energy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

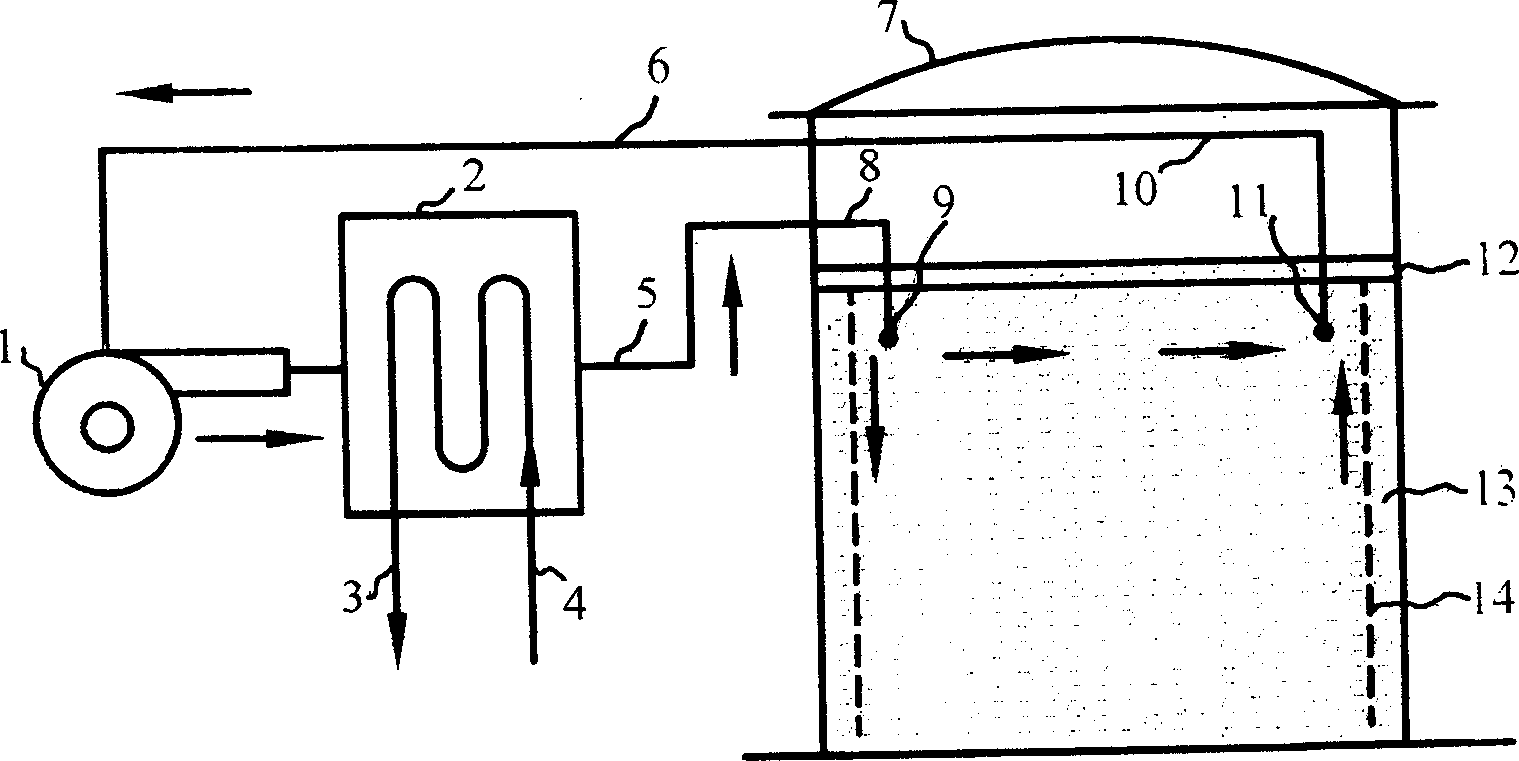

[0013] The present invention adopts the horizontal ventilation and cooling method, that is, adopts the method of horizontal air intake under the grain storage film on the south side of the bungalow 7 and the horizontal return air under the grain storage film on the north side of the bungalow to form a closed circulation; Circulation fan 1, surface cooler 2, external cold air supply pipe 5 connected with surface cooler 2, external cold air return pipe 6 connected with circulating fan 1, refrigerant outlet 3 and refrigerant inlet 4 connected with surface cooler 2 The connected refrigerator, at least one PVC air-conditioning air supply pipe 9 connected to the cold air supply pipe 5 outside the warehouse is provided in the east-west direction under the grain storage film on the south side of the warehouse, and the east-west direction is at least one under the grain storage film on the north side of the warehouse. A perforated PVC cold air return pipe 11 connected to the cold air re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com