Intelligent digitalized grain depot grain situation monitoring system

A technology of supervision system and grain situation, applied in the field of grain storage, can solve problems such as insufficient functions, data retention, untimely adjustment and management, etc., and achieve the effect of complete analysis functions, neat layout and simple installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to make it easy to understand the technical means, creative features, objectives and effects achieved by the present invention, the present invention will be further explained below in conjunction with specific drawings.

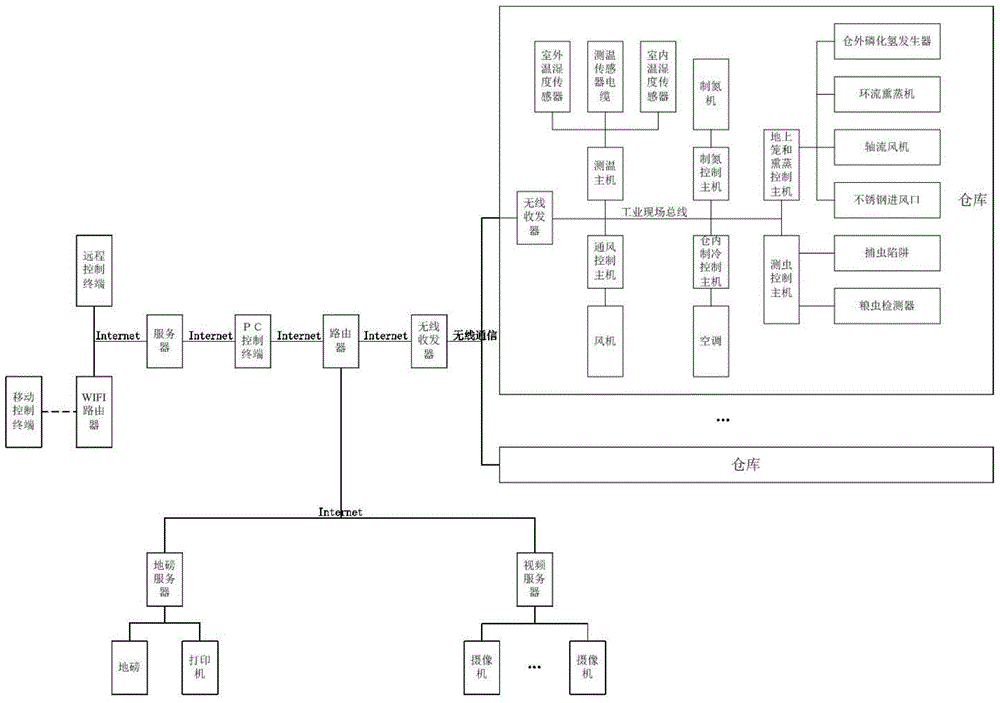

[0032] Such as figure 1 As shown, an intelligent digital grain depot grain condition monitoring system includes a grain condition measurement and control system installed in the warehouse, an intelligent ventilation system, a grain refrigeration system in the warehouse, a pest measurement system outside the warehouse, a nitrogen-filled grain storage system, an above-ground cage and Circulation fumigation system, platform scale weighing network system and video monitoring system; said platform scale weighing network system and video monitoring system are connected to PC control terminal via Internet and router, said grain condition monitoring system, intelligent ventilation system, The grain refrigeration system in the silo, the insect measurement...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com