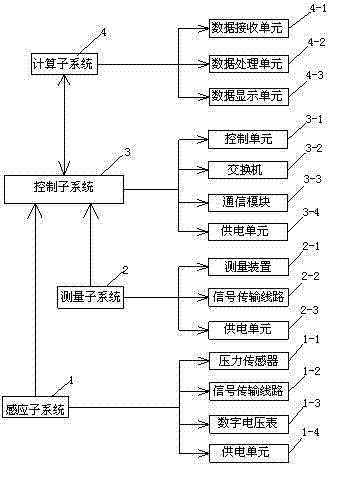

Granary capacity real-time monitoring system

A real-time monitoring system and monitoring system technology, which is applied in the field of monitoring the quantity of stored grain in grain bungalows, can solve the problems of storage capacity calculation influence, damage, and failure to consider dustproof and anti-corrosion issues, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

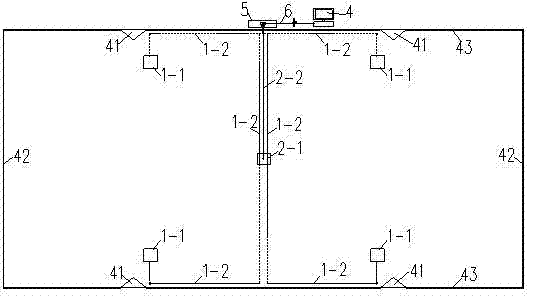

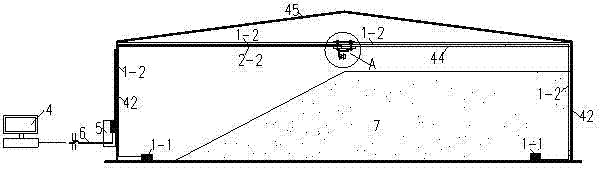

[0038] Such as figure 2 , image 3 As shown, the granary used in this embodiment is a one-story grain storehouse, the specific size is 60m x 24m x 9m in length, and the height of the grain loading line is 6m. The basic situation of grain storage is as follows: the storage material is wheat, and the storage volume is 791kg / m 3 ~793kg / m 3 , The temperature in the warehouse is 29 ℃, the relative humidity is 58.6%, without ventilation and fumigation, and the vibration of the surrounding environment is weak. When the warehouse is empty, a pressure sensor 1-1 is arranged at a position 3m away from the wall near the four warehouse doors 41, and a signal transmission line 1-2 is laid and led out of the warehouse from the warehouse to enter the control cabinet 5 on the outer wall of the warehouse.

[0039] Such as figure 2 , image 3 Shown, grain heap 7 is positioned at the lower part of grain line in the granary. Measuring mechanism suspension base is installed in the middle p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com