High-frequency vibration casting mold of conical sand maker rolling mortar wall and casting process

A conical sand making machine and high-frequency vibration technology, which is applied in the direction of manufacturing tools, casting molding equipment, casting molds, etc., can solve the problems of high crushing cost, poor casting density, and poor feeding effect, so as to avoid Damage phenomenon, improved impact resistance, good feeding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

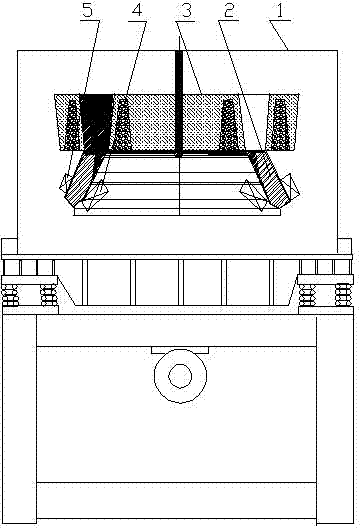

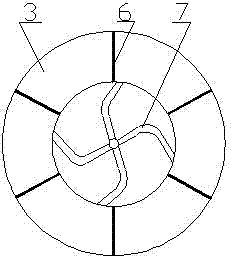

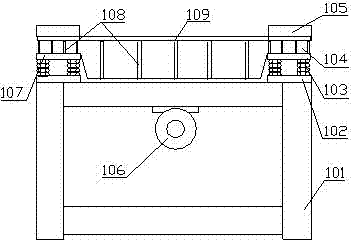

[0015] Embodiment 1: with reference to attached Figure 1-3 . A conical sand making machine rolling mortar wall high-frequency vibration pouring mold, the sand box 1 is located on the high-frequency vibration platform, the height of the molding cavity 2 of the rolling mortar wall in the sand box 1 is smaller than the height of the pouring riser 3 or the volume of the molding cavity 2 Smaller than the volume of the pouring riser 3, a plurality of riser spacers 6 are arranged around the pouring riser 3. The inner and outer walls of the mold cavity 2 for rolling the wall are provided with a plurality of built-in cold irons 4 and external cold irons 5 . The pouring riser 3 is provided with a plurality of runners 7 . The four corners of the rectangular support 101 of the high-frequency vibration platform are respectively provided with one or more compression springs 103, the compression springs 103 are provided with a pressure-bearing vibration platform 104, and the high-frequenc...

Embodiment 2

[0016] Example 2: On the basis of Example 1, a conical sand making machine rolling mortar wall high-frequency vibration pouring mold casting process, the sand box 1 is located on the high-frequency vibration platform, and the mortar wall molding cavity 2 is formed in the sand box 1 The height is less than the height of the pouring riser 3 or the volume of the molding cavity 2 is less than the volume of the pouring riser 3. The high-chromium cast iron is poured into the rolling wall molding cavity 2 and the pouring riser 3, and then the high-frequency vibration is carried out on the high-frequency vibration platform. After vibration and cooling, a high-density high-chromium cast iron rolling mortar wall can be obtained. The weight of the high chromium cast iron rolling wall is less than that of the pouring riser. A circle of the pouring riser 3 is provided with a plurality of riser spacers 6 . The vibration frequency of the high-frequency vibration platform is greater than 200...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com