Patents

Literature

37results about How to "Reduce the cost of sand making" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

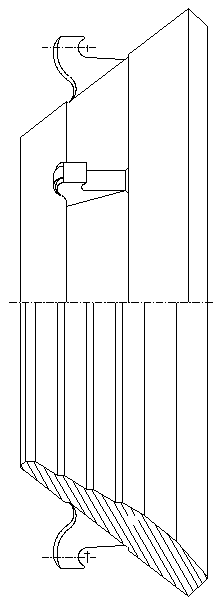

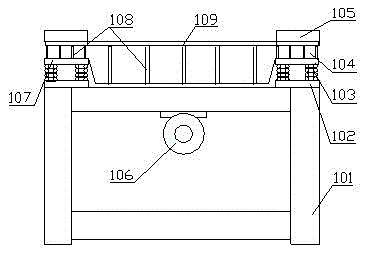

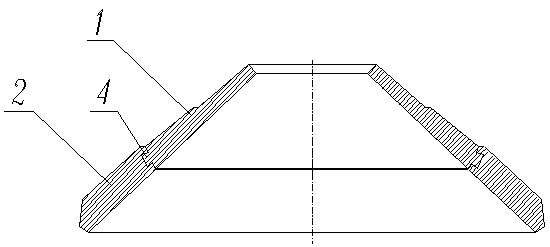

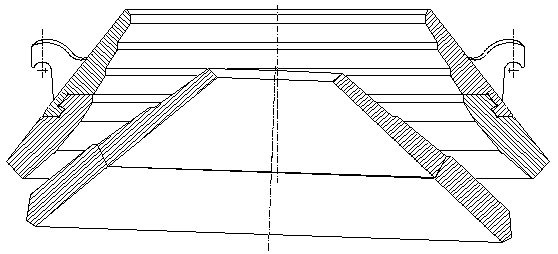

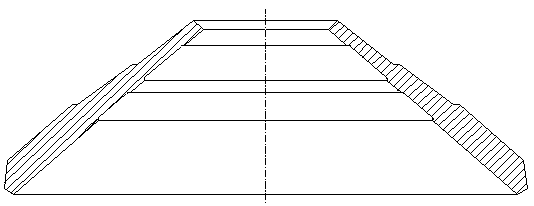

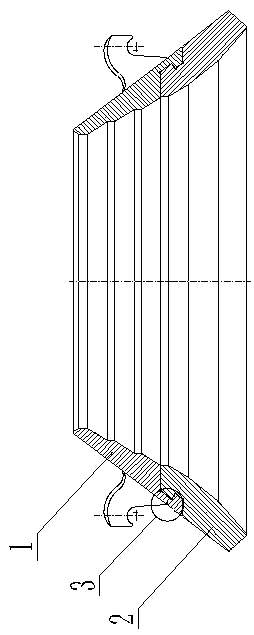

High-frequency vibration casting mold of conical sand maker rolling mortar wall and casting process

ActiveCN102962398AImprove wear resistanceReduce the cost of sand makingFoundry mouldsFoundry coresChromiumCast iron

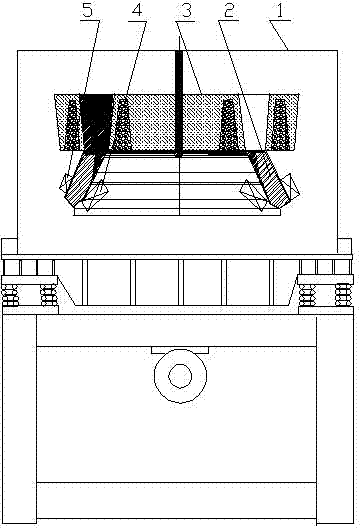

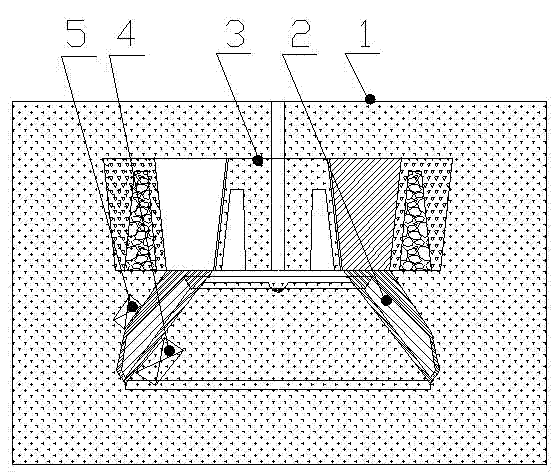

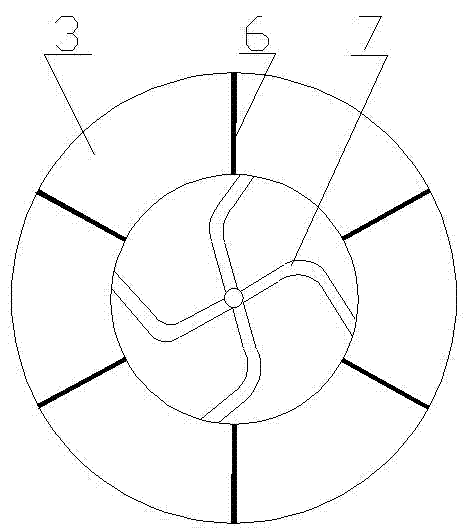

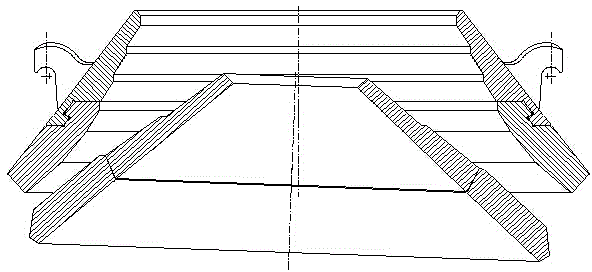

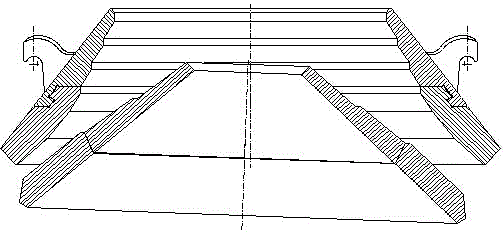

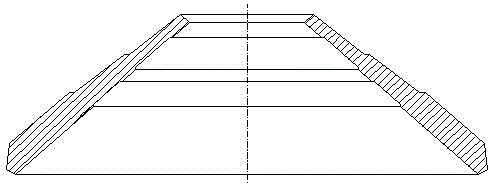

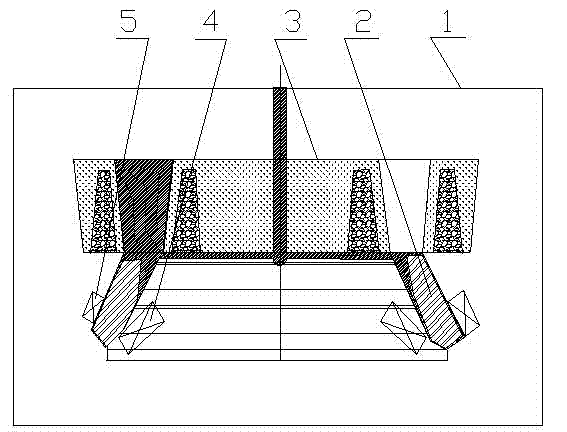

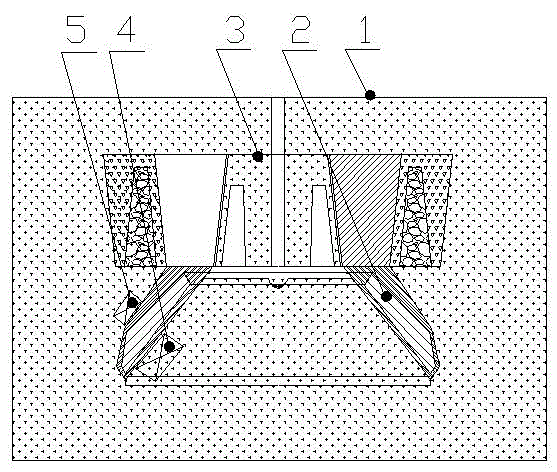

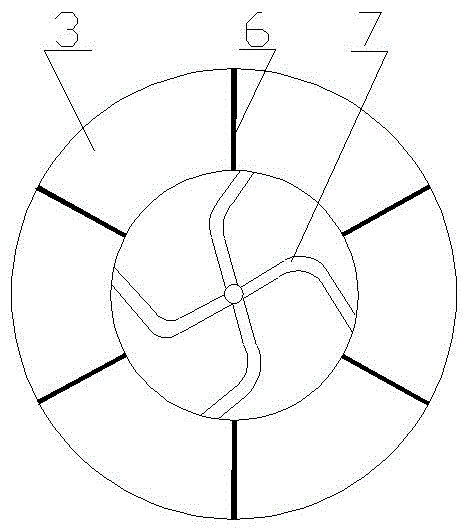

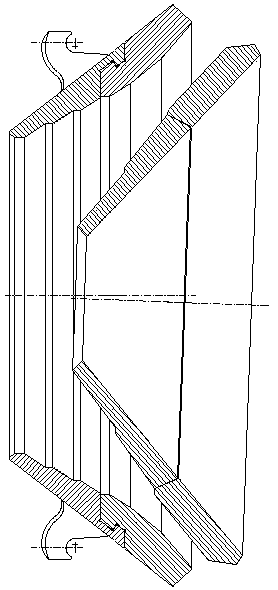

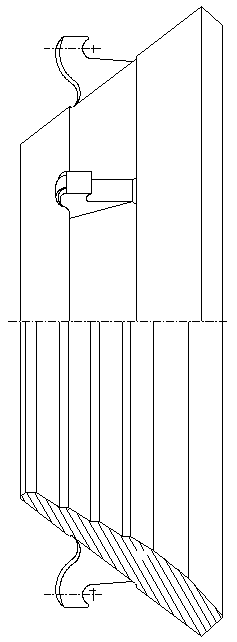

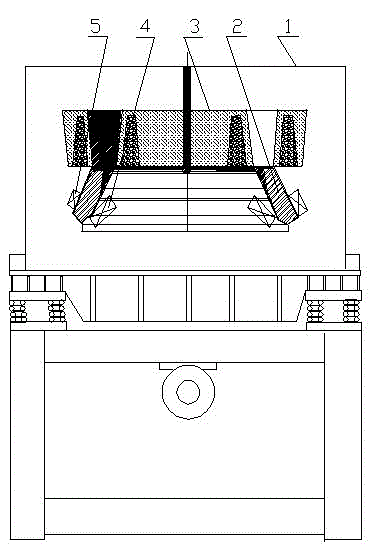

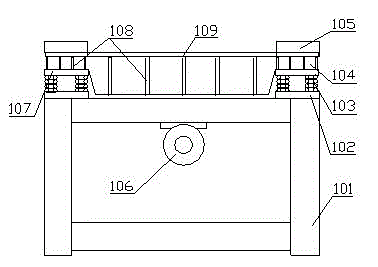

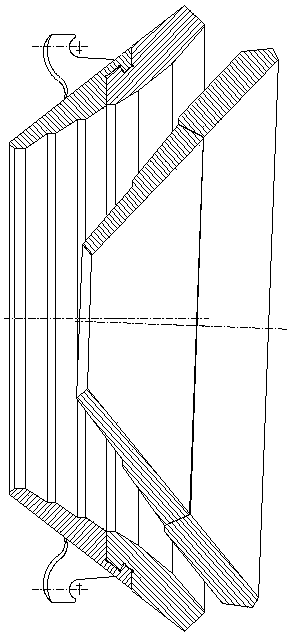

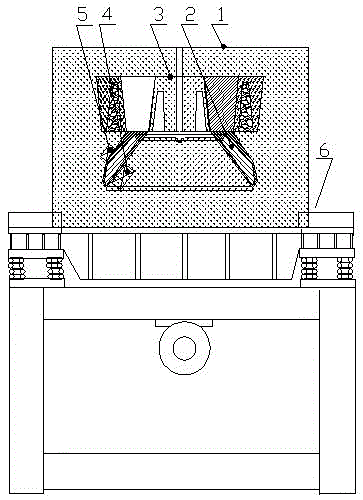

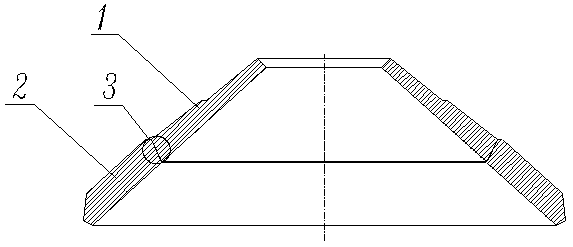

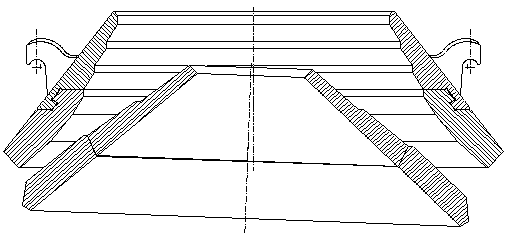

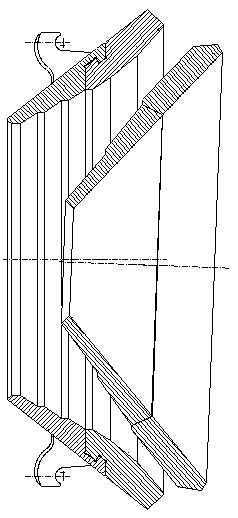

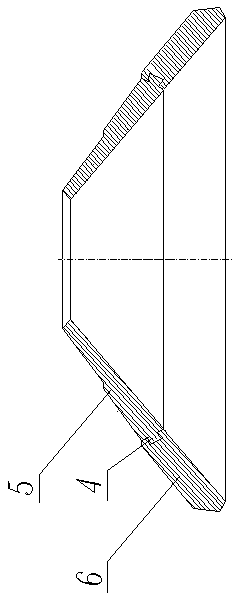

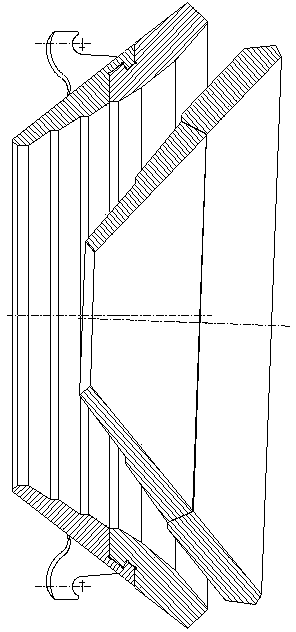

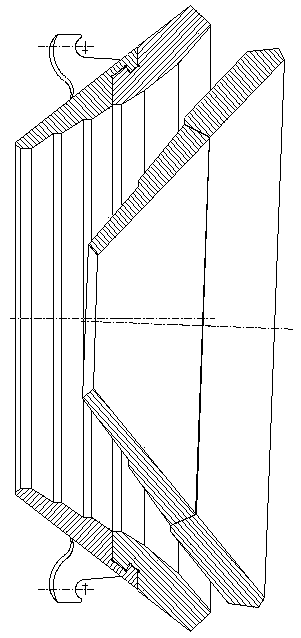

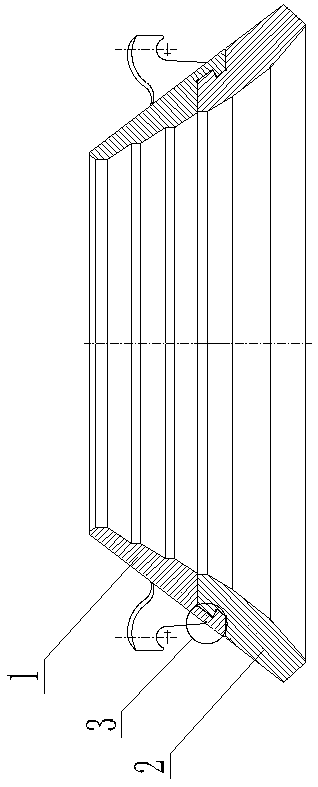

The invention relates to a high-frequency vibration casting mold of a conical sand maker rolling mortar wall and a casting process capable of achieving the effect of no shrinkage cavity and effectively improving the cast density during casting feeding of the conical sand maker rolling mortar wall. The high-frequency vibration casting mold is characterized in that a sand box is located on a high-frequency vibration platform; the height of a rolling mortar wall forming mold cavity in the sand box is smaller than the height of a casting riser or the volume of the forming mold cavity is smaller than the volume of the casting riser. The casting process comprises the following steps: casting high chromium cast iron into the rolling mortar wall forming mold cavity and the casting riser, then carrying out high-frequency vibration on the high-frequency vibration platform, and cooling to obtain the high chromium cast iron rolling mortar wall with a high density. The high-frequency casting mold and the casting process have the advantages that firstly, the wear resistance of the high chromium cast iron rolling mortar wall is effectively improved, and the sand making cost is greatly reduced; secondly, the feeding effect is good, the cast is high in density, and the occurrence of damage phenomenon is avoided; and thirdly, the wear resistance, the shock resistance and the service life are increased by nearly 5 times, and unexpected technical effects are achieved.

Owner:ZHEJIANG SHUANGJIN MACHINERY HLDG

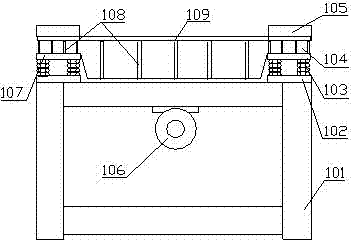

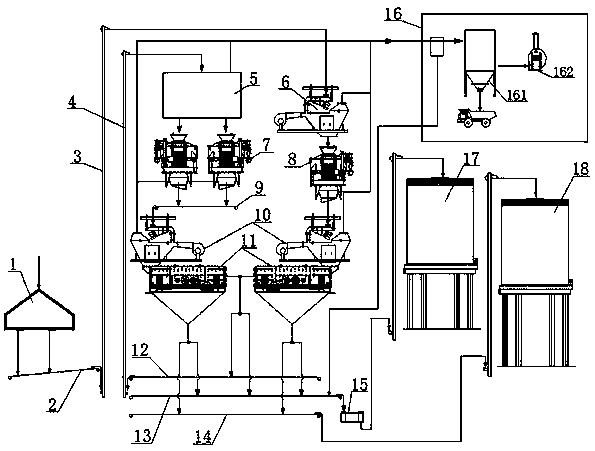

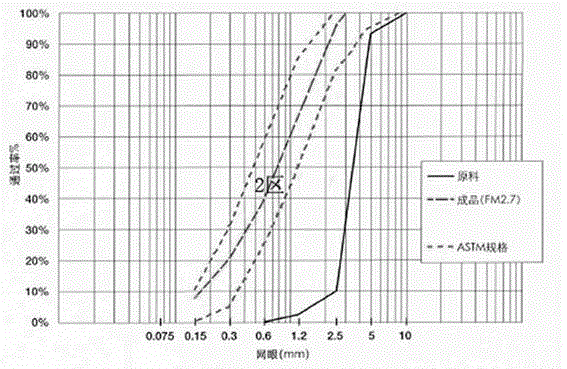

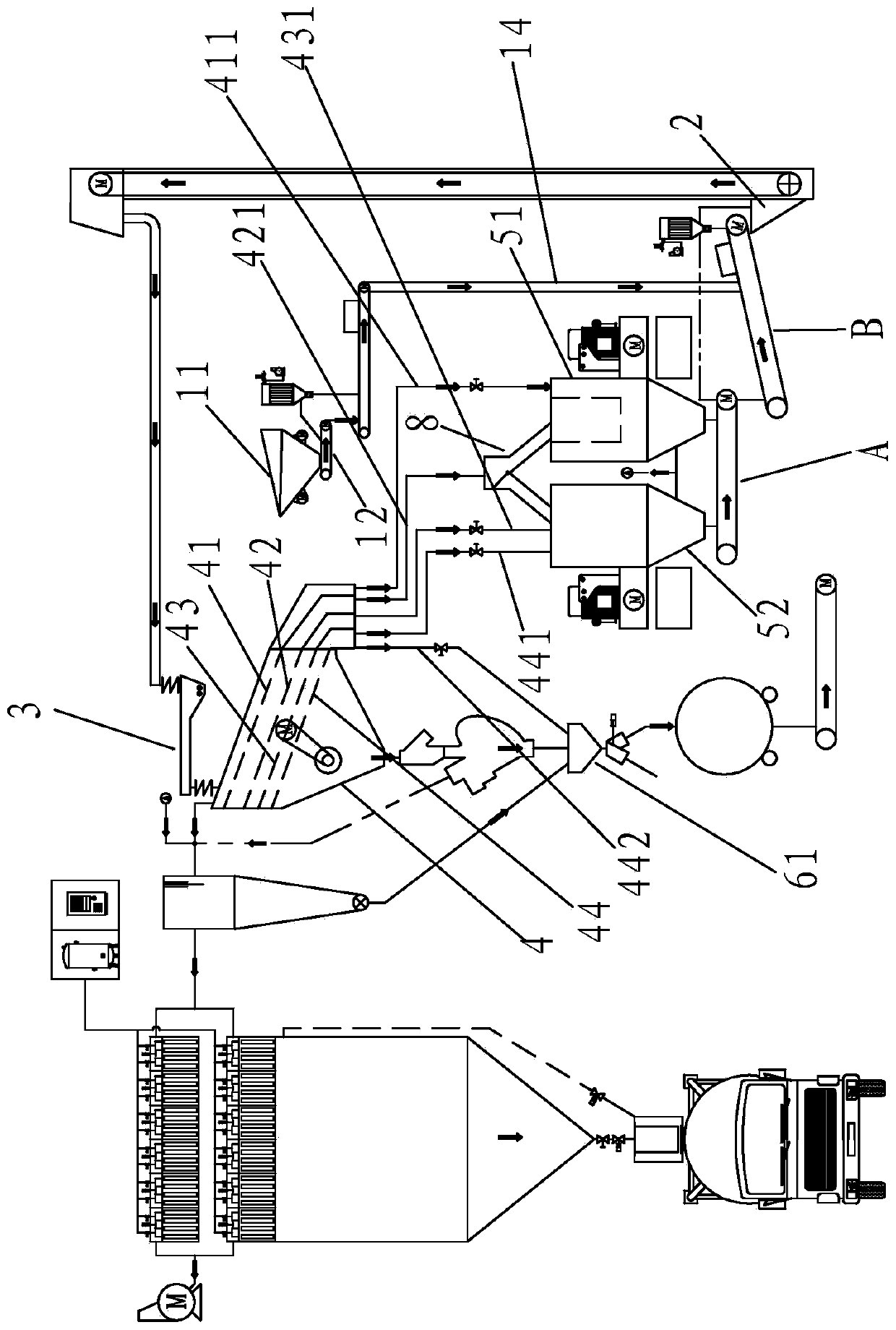

Machine-made sand production station and sand making method

The invention discloses a machine-made sand production station and a sand making method. The machine-made sand production station comprises a steel structure framework, a vibrator feeder, a powder removal machine, a sand-making machine, a shaper, a screening machine and dust removal equipment, and adopts a novel layout manner as follows: the sand-making machine is arranged on the top of the steelstructure framework, the screening machine with high vibration is arranged at the bottom, and the screening machine is separated from the structure framework, so that vibration of the steel structureis reduced, the weight of the steel structure of the station is reduced on premise of ensuring the safety, and investment of the production station is reduced. Two sand-making machines are used for simultaneously making sand, and a novel manner of matching the shaper and two screening machines is adopted, so that the sand making efficiency is improved, the grains of finished sand are full and round and more regular. The powder removal machines are arranged at a feeding hole and a discharging hole of the shaper, and a two-stage powder removal process is adopted, so that stone powder content ofthe finished sand can be effectively controlled, and the quality of the finished sand is improved.

Owner:GUIZHOU CHENGZHI HEAVY IND SCI TECH

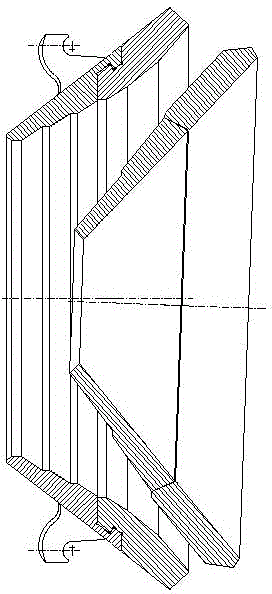

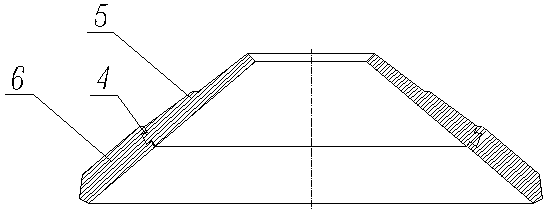

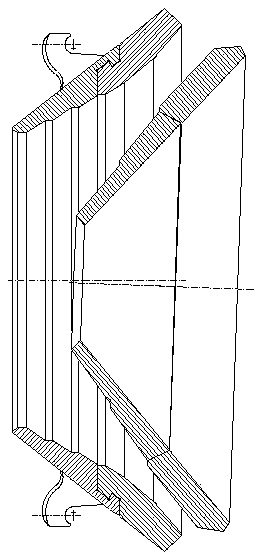

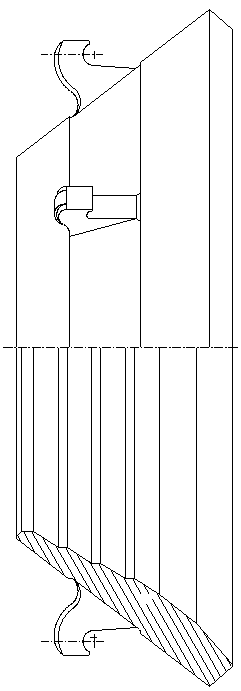

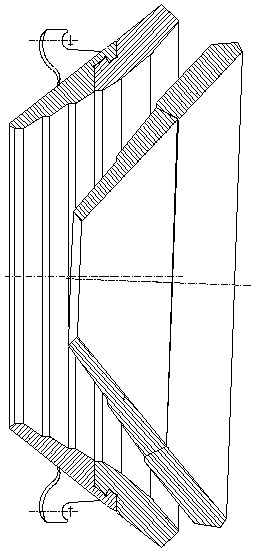

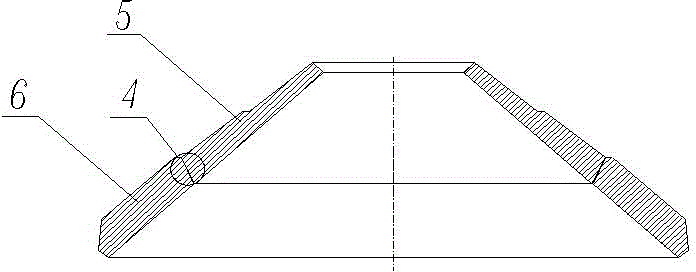

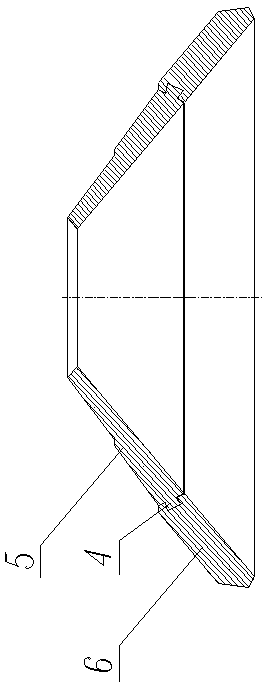

Casting mold of conical sand maker breaking wall and casting process

ActiveCN102962397AImprove wear resistanceReduce the cost of sand makingFoundry mouldsFoundry coresChromiumCast iron

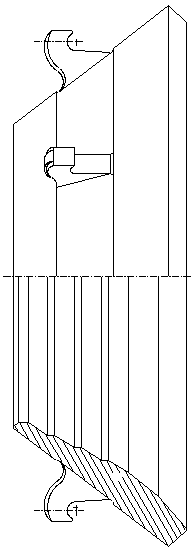

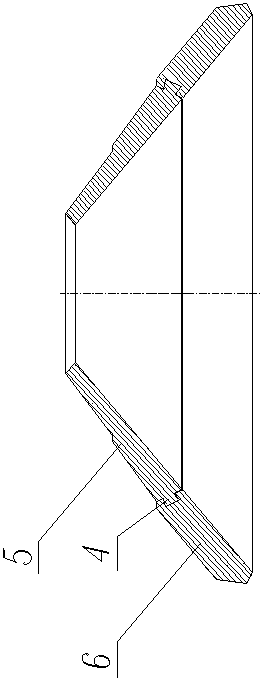

The invention relates to a casting mold of a conical sand maker breaking wall and a casting process capable of achieving the effect of no shrinkage cavity and effectively improving the cast density during casting feeding of the conical sand maker breaking wall. The casting mold is characterized in that the height of a breaking wall forming mold cavity in the sand box is smaller than the height of a casting riser or the volume of the forming mold cavity is smaller than the volume of the casting riser. The casting process comprises the following steps: casting high chromium cast iron into the breaking wall forming mold cavity and the casting riser, then suspending the sand box on a high-frequency vibration platform for high-frequency vibration, and cooling to obtain the high chromium cast iron breaking wall with a high density. The casting mold and the casting process have the advantages that firstly, the wear resistance of the high chromium cast iron breaking wall is effectively improved, and the sand making cost is greatly reduced; secondly, the feeding effect is good, the cast is high in density, and the occurrence of damage phenomenon is avoided; and thirdly, the wear resistance, the shock resistance and the service life are increased by nearly 5 times, and unexpected technical effects are achieved.

Owner:ZHEJIANG SHUANGJIN MACHINERY HLDG

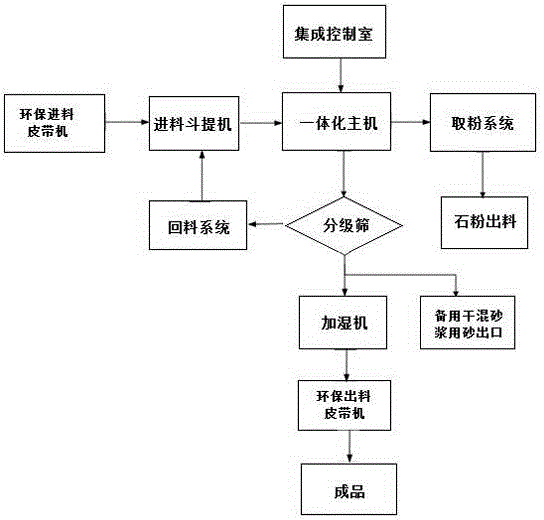

Dry sand making process

The invention discloses a dry sand making process, comprising the following procedures: crushing treatment, sieving treatment, coarse particle humidification treatment and standby dry sand treatment. The process integrates striking, milling and rocking by stones; meanwhile, stone-powder separation is achieved; kinetic energy required by a main engine is greatly reduced; the produced product is stable in grading, good in particle shape, and adjustable in fineness modulus; the overall process adopts a separation technique, so that energy conservation and environmental protection are achieved; the finished product is stable in grading, good in particle shape, and free of needle-like sand, and is a polyhedron, and is similar to a globoid shape; the fineness modulus (2.3-3.0) and the particle content (below 5%) are adjustable; all performance indexes accord with the 'standard of sand for construction' GB14684-2011; the processing cost per ton is saved by 60% in comparison with international and domestic similar products; the sand making cost is greatly reduced; and the crushing application range is wide.

Owner:TAI ZHOU TENG DA CONSTR ENG MACHINERY

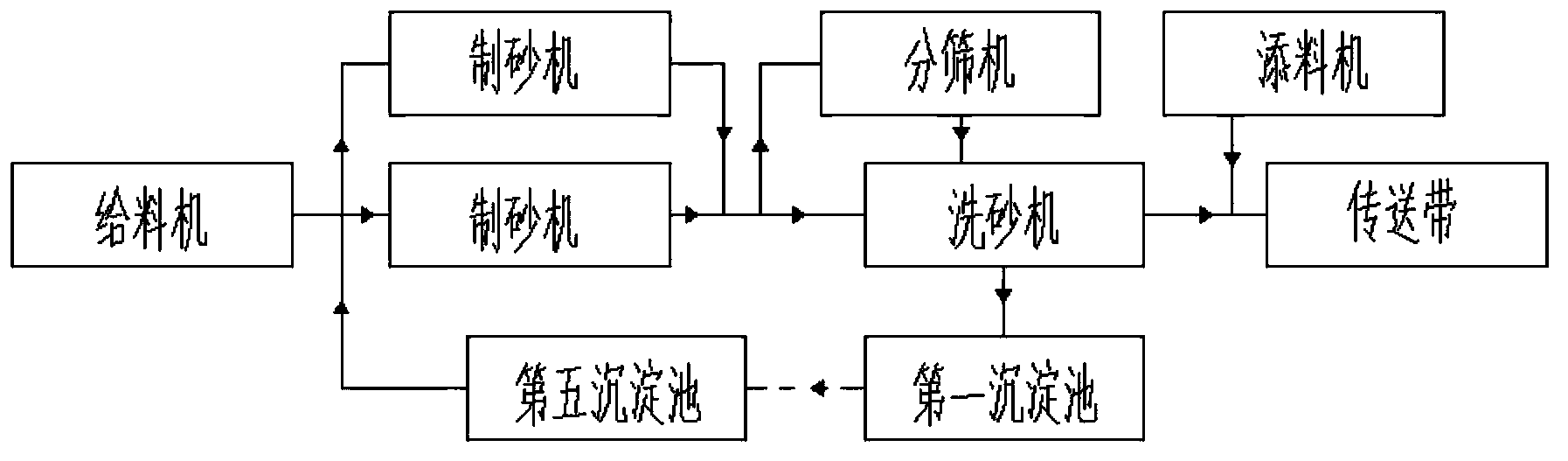

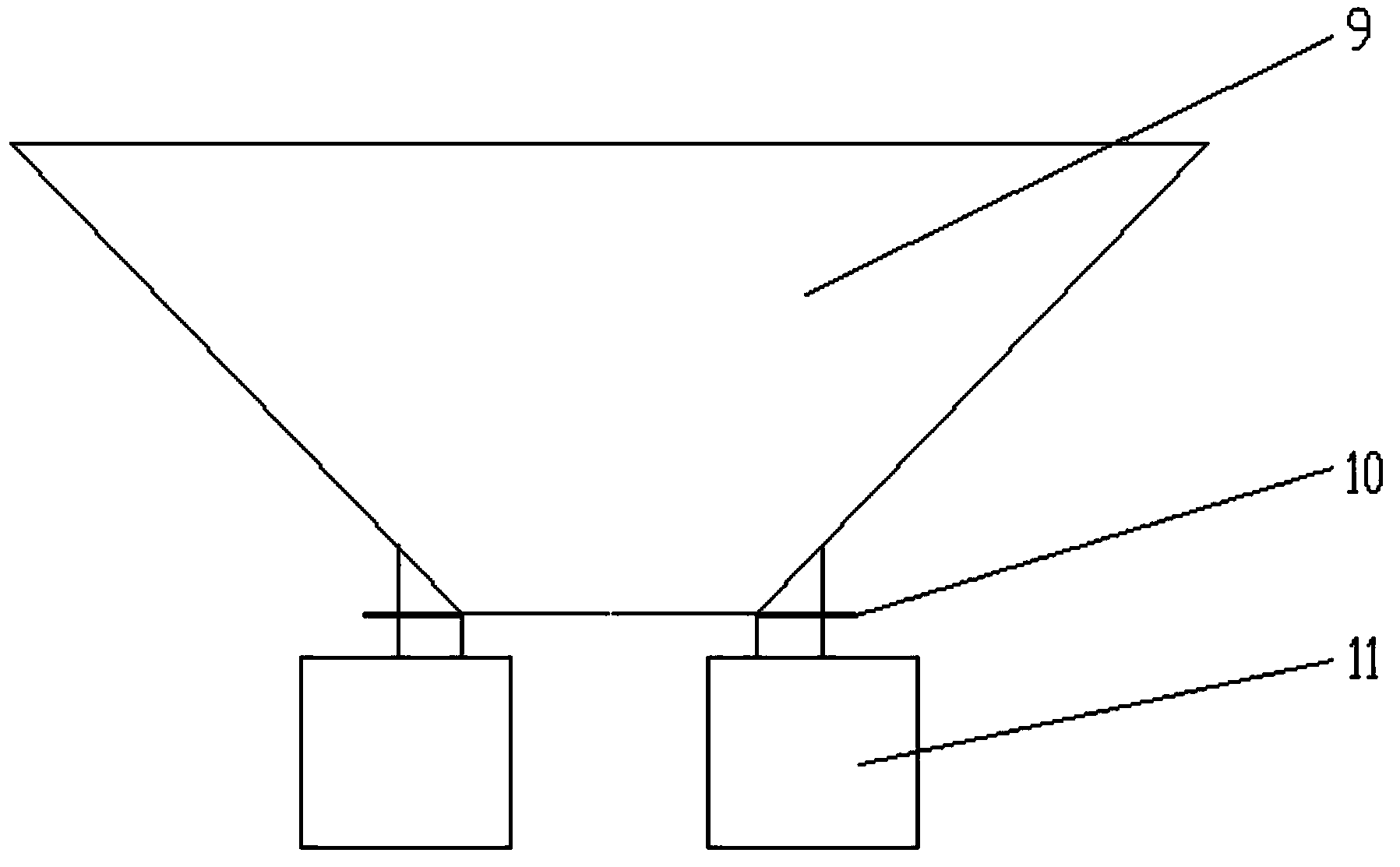

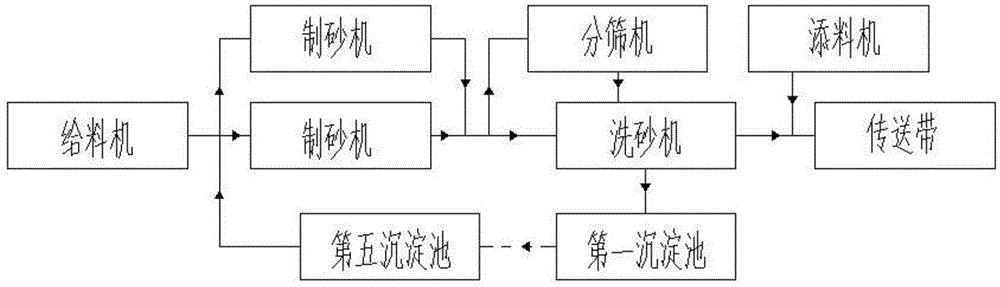

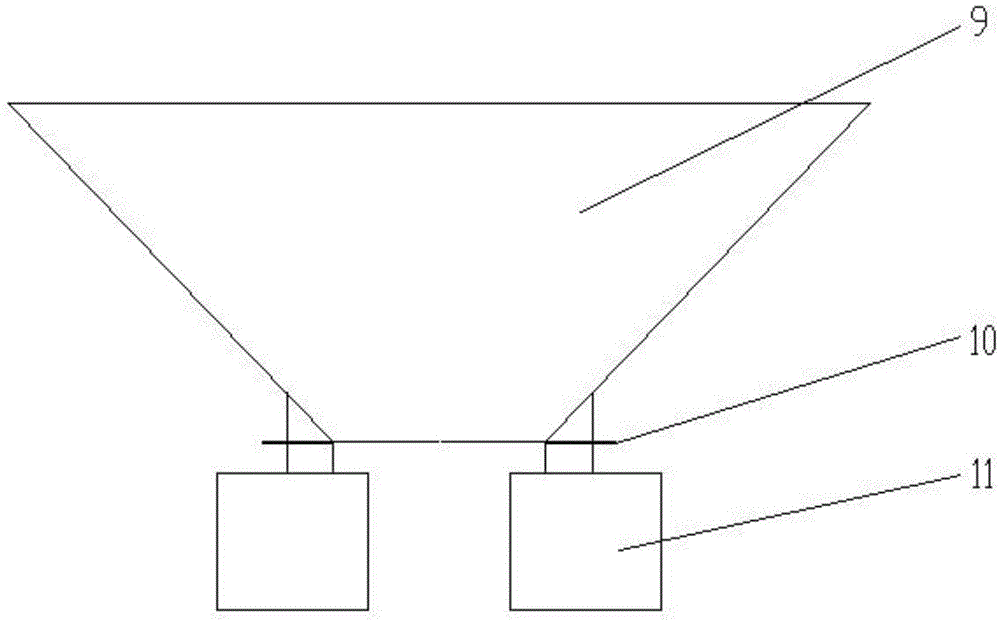

Production line for producing sand

InactiveCN103406185AReduce pollutionTake advantage ofGrain treatmentsWet separationProduction lineEngineering

The invention relates to a production line for producing sand, which comprises a feeding machine, sand producing machines, a sand washer and sedimentation tanks, wherein the number of the sand producing machines is N, and N is an integral number not less than 1; feed inlets are formed in the sand producing machines; the feed inlets comprise stone inlets and water inlets; the feeding machine is respectively connected with the feed inlets of the N sand producing machines; the feed inlets of the N sand producing machines are respectively connected with the sedimentation tanks through pipelines; discharge outlets of the N sand producing machines are respectively connected with the sand washer; the sand washer is connected with the sedimentation tanks through pipelines. According to the invention, a cyclically utilized production line is formed, on one hand, the sand producing efficiency is improved, and the sand producing cost is reduced, and on the other hand, noise, dust and sewage pollution during the sand producing process are reduced, various intermediate products are enabled to be fully utilized, and the requirements of the present market are satisfied.

Owner:李小福

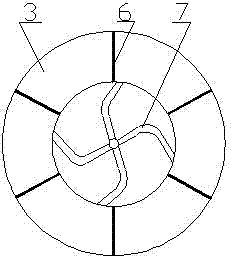

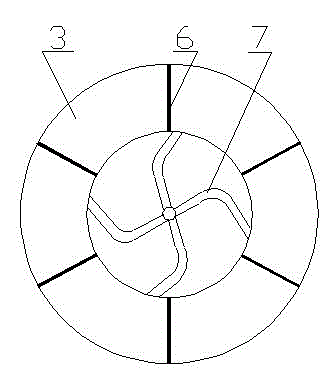

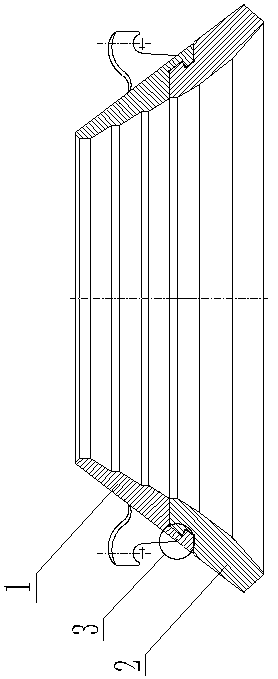

Cone sand maker rolling-based sand making cavity assembly being smaller than 2000 mm in diameter and manufacturing method

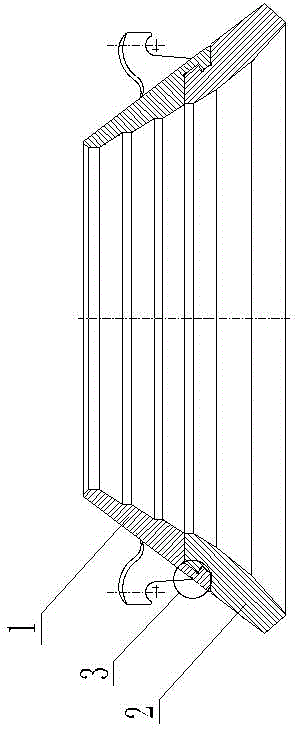

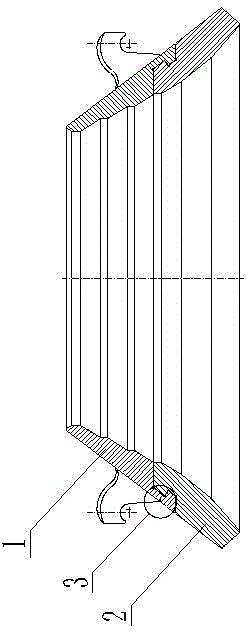

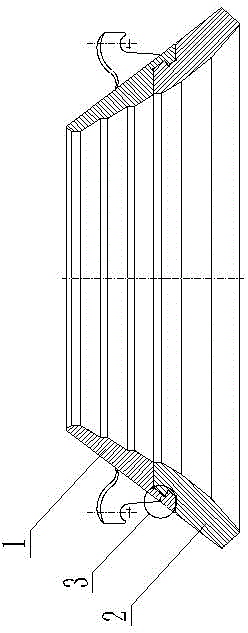

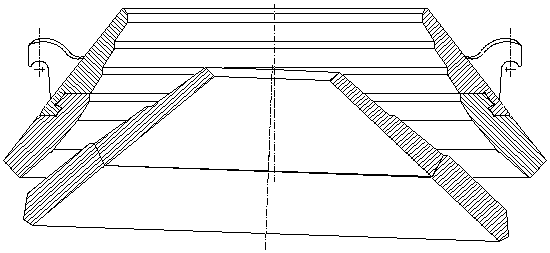

The invention relates to a cone sand maker rolling-based sand making cavity assembly being smaller than 2000 mm in diameter and a manufacturing method. The cone sand maker rolling-based sand making cavity assembly comprises a rolling mortar wall and a crushing wall, wherein the upper parts of the rolling mortar wall and the crushing wall are made of high manganese steel, and the lower parts thereof are made of high-carbon chromium steel. The cone sand maker rolling-based sand making cavity assembly has the following advantages: (1) the fatal defect that sand making cannot be performed during the sand making process because the single material rolling mortar wall and a single material crushing wall suffer different abrasion losses from different sized stones, the upper parts of the single material rolling mortar wall and the single material crushing wall are slightly abraded while the lower parts thereof are seriously abraded, and a groove is formed in a rolling-based sand making cavity can be fundamentally overcome; (2) the abrasion loss caused by high manganese steel at the upper parts of the rolling mortar wall and the crushing wall during the stone crushing process is relatively consistent with that of the rolling-based sand making cavity in the high-carbon chromium steel lower part of the rolling mortar wall, so that not only are the service lives of the rolling mortar wall and the crushing wall greatly prolonged, but also the sand making cost is reduced on the premise that the use costs of the rolling mortar wall and the crushing wall are greatly reduced.

Owner:ZHEJIANG SHUANGJIN MACHINERY HLDG

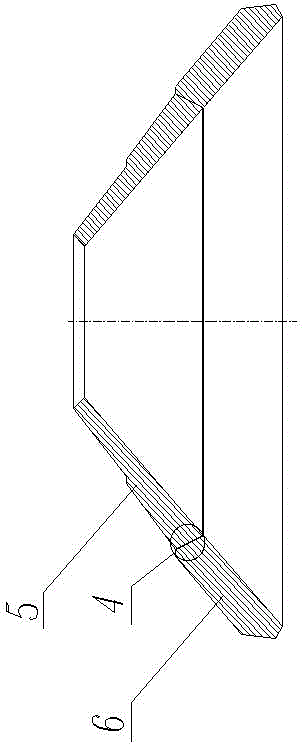

Cone sand maker two-component crushing wall being smaller than 2000 mm in diameter and manufacturing method

The invention relates to a cone sand maker two-component crushing wall being smaller than 2000 mm in diameter and a manufacturing method, and aims to meet not only the abrasion-resistant requirement of stone crushing but also the abrasion-resistant requirement of rolling-based sand making during a sand making process. The upper part and the lower part of the cone sand maker two-component crushing wall are made of high manganese steel and high-carbon chromium steel respectively. The cone sand maker two-component crushing wall has the following advantages: (1) the fatal defect that sand making cannot be performed during the sand making process because a single material rolling mortar wall suffers different abrasion losses from different sized stones, the upper part of the single material rolling mortar wall is slightly abraded while the lower part thereof is seriously abraded, and a groove is formed in a rolling-based sand making cavity can be fundamentally overcome; (2) the abrasion loss caused by high manganese steel at the upper part of the cone sand maker two-component crushing wall during the stone crushing process is relatively consistent with that of the rolling-based sand making cavity in the high-carbon chromium steel lower part of the cone sand maker two-component crushing wall.

Owner:ZHEJIANG SHUANGJIN MACHINERY HLDG

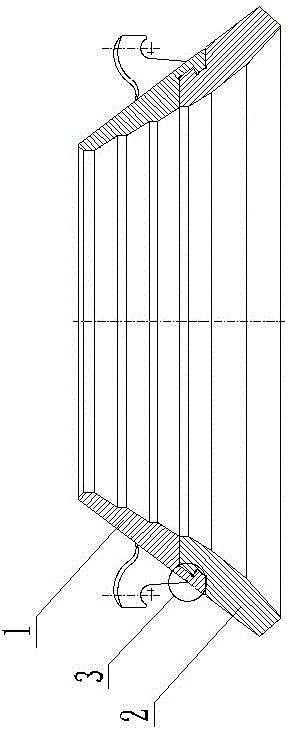

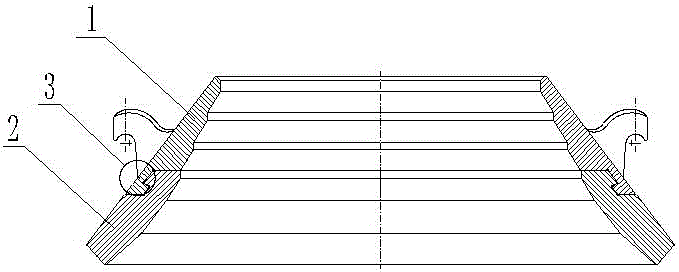

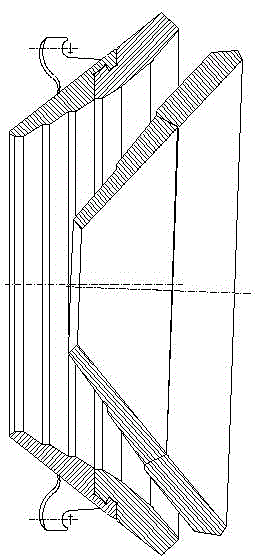

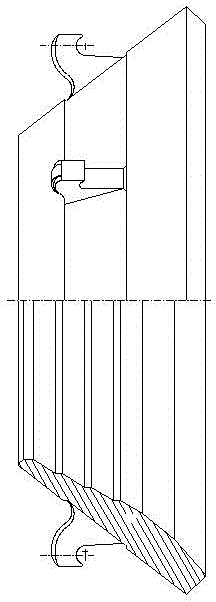

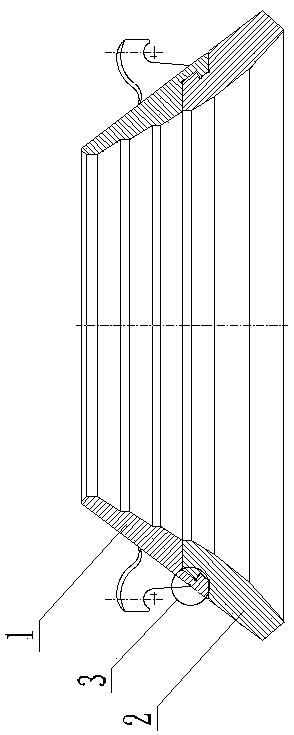

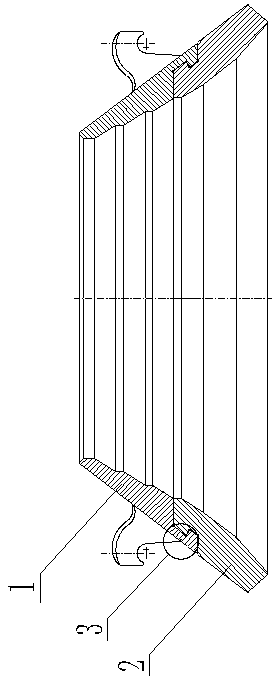

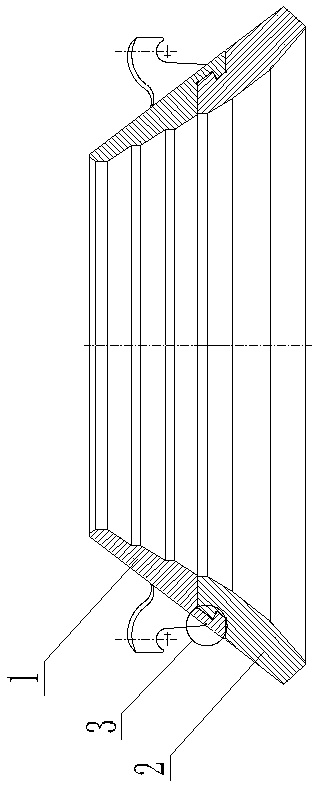

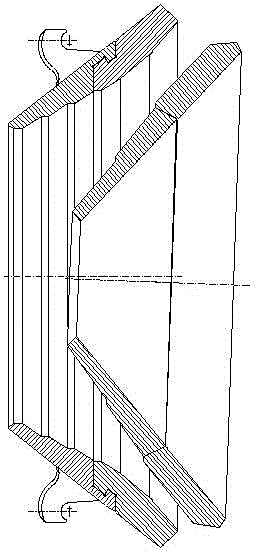

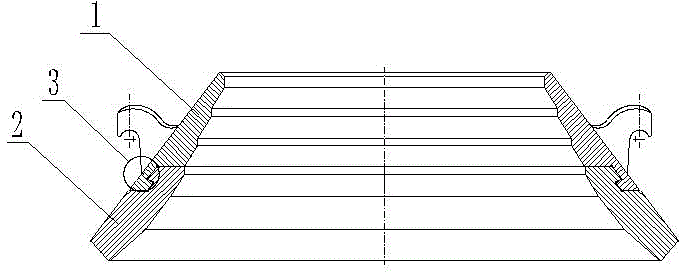

Casting mold of conical sand maker rolling mortar wall and casting process

ActiveCN102962400AImprove wear resistanceHigh densityFoundry mouldsFoundry coresHigh densityCasting mold

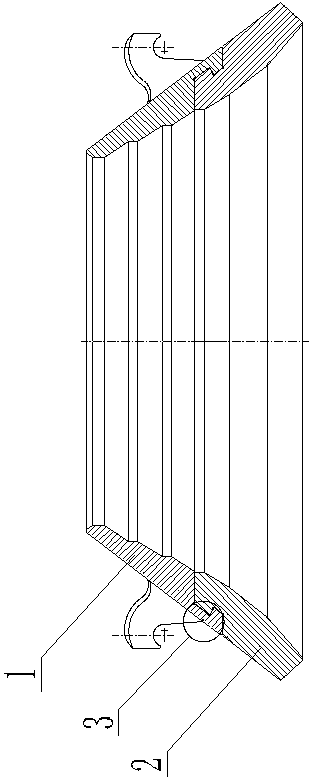

The invention relates to a casting mold of a conical sand maker rolling mortar wall and a casting process capable of achieving the effect of no shrinkage cavity and effectively improving the cast density during casting feeding of the conical sand maker rolling mortar wall. The casting mold is characterized in that the height of a rolling mortar wall forming mold cavity in the sand box is smaller than the height of a casting riser or the volume of the forming mold cavity is smaller than the volume of the casting riser. The casting process comprises the following steps: casting high chromium cast iron into the rolling mortar wall forming mold cavity and the casting riser, then suspending the sand box on a high-frequency vibration platform for high-frequency vibration, and cooling to obtain the high chromium cast iron rolling mortar wall with a high density. The casting mold and the casting process have the advantages that firstly, the wear resistance of the high chromium cast iron rolling mortar wall is effectively improved, and the sand making cost is greatly reduced; secondly, the feeding effect is good, the cast is high in density, and the occurrence of damage phenomenon is avoided; and thirdly, the wear resistance, the shock resistance and the service life are increased by nearly 5 times, and unexpected technical effects are achieved.

Owner:ZHEJIANG SHUANGJIN MACHINERY HLDG

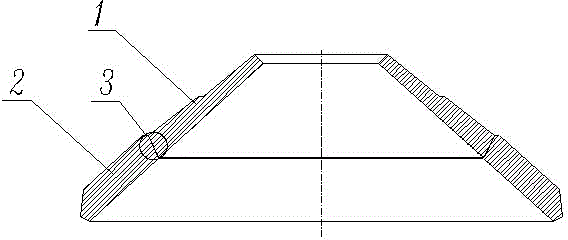

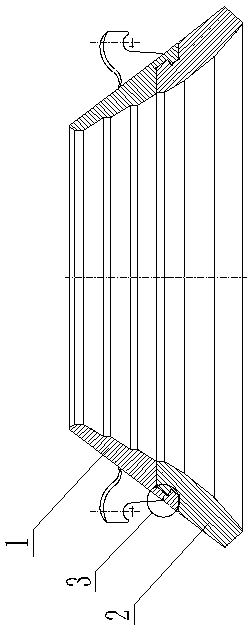

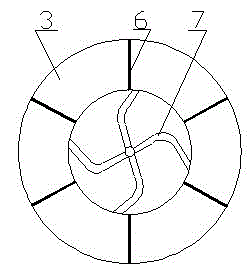

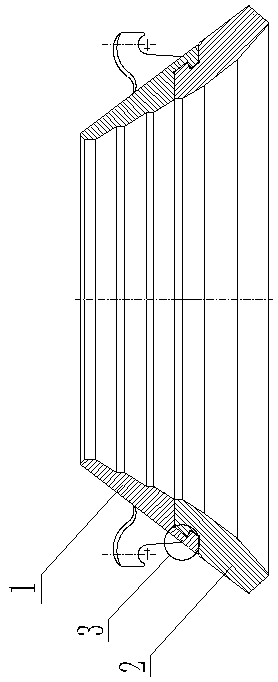

Double component rolled mortar wall for cone sand making machine and manufacturing method

ActiveCN104801378AExtended service lifeReduce use costGrain treatmentsCrushed stoneMechanical engineering

The invention relates to a double component rolled mortar wall for a cone sand making machine and a manufacturing method. The double component rolled mortar wall can meet not only the abrasion resistant requirements on broken stone crushing but also the abrasion resistant requirements on rolling sand making when the cone sand making machine is in the sand making process. The upper part of the rolled mortar wall is made of Mn13, the lower part of the rolled mortar wall is made of high-chromium cast iron, and a ring-shaped groove is formed in the outer wall or the inner wall at the lower part of the rolled mortar wall, and is in concave-convex fusion casting coordination with a ring-shaped groove formed in the inner wall or the outer wall at the upper part of the rolled mortar wall. The double component rolled mortar wall has the advantages that 1, the critical defects that in the sand making process on the rolled mortar wall made of a single material, the abrasion losses on the rolled mortar wall by stone materials in different specifications are different, so that the upper part of the rolled mortar wall is slightly abraded while the lower part of the rolled mortar wall is seriously abraded, then a groove is formed in a rolling sand making cavity, and the sand cannot be made, are solved radically; 2, the abrasion loss of the Mn13 at the upper part of the rolled mortar wall when the stone materials are crushed is in relative accordance with the abrasion loss of the rolling sand making cavity at the lower part of the high-chromium cast iron rolled mortar wall.

Owner:ZHEJIANG SHUANGJIN MACHINERY HLDG

Casting mold and casting process for broken wall of cone sand making machine

ActiveCN102962397BImprove wear resistanceHigh densityFoundry mouldsFoundry coresHigh densityVolumetric Mass Density

The invention relates to a casting mold of a conical sand maker breaking wall and a casting process capable of achieving the effect of no shrinkage cavity and effectively improving the cast density during casting feeding of the conical sand maker breaking wall. The casting mold is characterized in that the height of a breaking wall forming mold cavity in the sand box is smaller than the height of a casting riser or the volume of the forming mold cavity is smaller than the volume of the casting riser. The casting process comprises the following steps: casting high chromium cast iron into the breaking wall forming mold cavity and the casting riser, then suspending the sand box on a high-frequency vibration platform for high-frequency vibration, and cooling to obtain the high chromium cast iron breaking wall with a high density. The casting mold and the casting process have the advantages that firstly, the wear resistance of the high chromium cast iron breaking wall is effectively improved, and the sand making cost is greatly reduced; secondly, the feeding effect is good, the cast is high in density, and the occurrence of damage phenomenon is avoided; and thirdly, the wear resistance, the shock resistance and the service life are increased by nearly 5 times, and unexpected technical effects are achieved.

Owner:ZHEJIANG SHUANGJIN MACHINERY HLDG

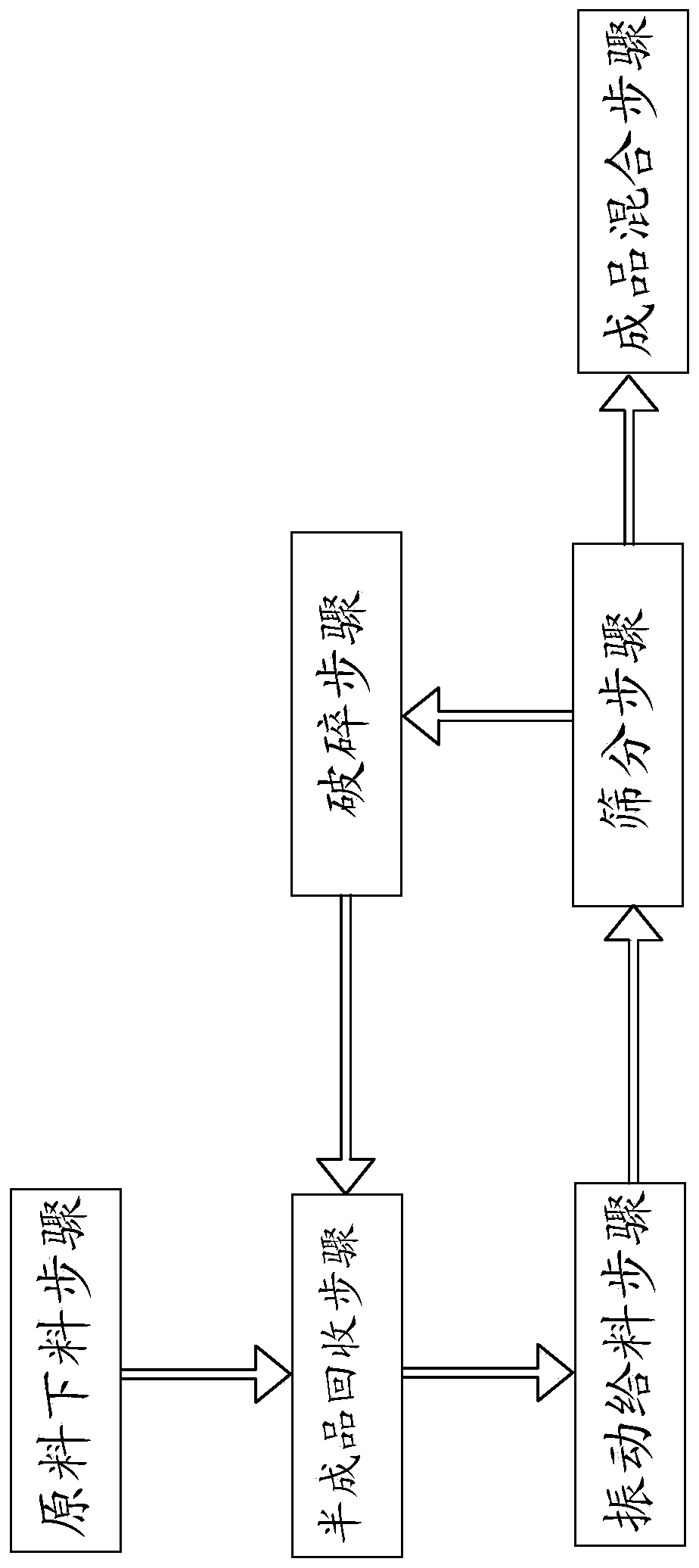

Selective crushing sand making process after mixed aggregate pre-screening

PendingCN111389564AImprove crushing efficiencyReduce crushing energy consumptionSievingScreeningProcess engineeringCrusher

The invention discloses a selective crushing sand making process after mixed aggregate pre-screening. The process comprises a raw material discharging step, a raw material conveying step, a vibrationfeeding step, a screening step and a crushing step; a first crusher and a second crusher are arranged in the crushing step, and the first crusher and the second crusher are vertical shaft impact crushers; raw materials is output through the raw material discharging step and then sequentially passes through the raw material conveying step, the vibration feeding step, the screening step and the crushing step, and the crushed coarse materials and raw materials in the raw material discharging step are output through the raw material conveying step for circle operation; and the coarse materials screened out by an uppermost screen in the screening step fall into a waterfall feeding port in the first crusher in the crushing step. Compared with the prior art, the process has the beneficial effectsthat the raw materials are crushed after being screened, and then are screened and crushed after being crushed to form a closed-loop system, so that the crushing energy consumption is reduced, the crushing effect is good, the selection between low-rotating-speed crushing and high-rotating-speed crushing is realized according to the raw materials with different particle sizes, and the crushing efficiency is greatly improved.

Owner:FUJIAN NONNON TECH

Conical sand making machine rolling cavity assembly and method composed of mn13 and high chromium cast iron

The invention relates to a conical sand making machine rolling cavity assembly made of Mn13 and high-chromium cast iron and a making method, the conical sand making machine rolling cavity assembly can not only meet the wear-resisting requirement of gravel crushing, but also can meet the wear-resisting requirement of rolling and sand making during the process of sand making by using a conical sand making machine. The upper part of a rolling wall is made of Mn13, the lower part of the rolling wall is made of high-chromium cast iron, and the upper part of the rolling wall and the lower part of the rolling wall are in concave-convex casting matching; the upper part of a crushing wall is made of Mn13, the lower part of the crushing wall is made of high-chromium cast iron, and the upper part of the crushing wall and the lower part of the crushing wall fit are in concave-convex casting matching. The conical sand making machine rolling cavity assembly made of Mn13 and high-chromium cast iron and the making method have the advantages as follows: the critical defect that sand making cannot be carried out due to the fact a groove is formed in a rolling and sand making cavity is fundamentally overcome, the defect is caused by the fact that little wear is produced at the upper parts of the rolling wall and the crushing wall and serious wear is produced at the lower parts of the rolling wall and the crushing wall, because stones with different specifications have different wearing capacities on the rolling wall and the crushing wall; besides, the wearing capacities of the upper parts of the rolling wall and the crushing wall made of Mn13 during stone crushing is in relative consistent with that of the lower part of the crushing wall made of high-chromium cast iron when rolling a sand making cavity.

Owner:ZHEJIANG SHUANGJIN MACHINERY HLDG

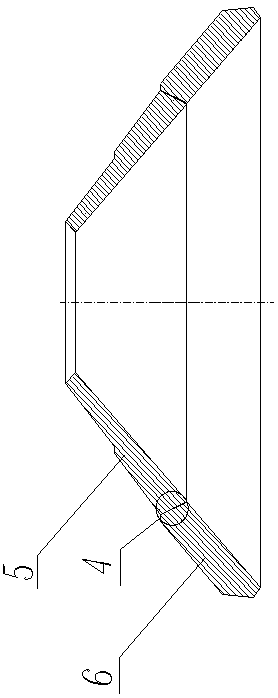

Rolling mortar wall of conical sand making machine, made of Mn13 and high-chromium iron, and method

The invention relates to a rolling mortar wall of a conical sand making machine and a manufacturing method, wherein the rolling mortar wall of the conical sand making machine is made of Mn13 and high-chromium iron, not only can meet the wear-resistant requirement of aggregate crushing , but also can meet the wear-resistant requirement of rolling for sand making during a sand making process, the upper part of a rolling mortar wall is made of Mn13, the lower part of the rolling mortar wall is made of the high-chromium iron, and the upper part of the rolling mortar wall and the lower part of the rolling mortar wall are in concave-convex casting matching. The rolling mortar wall provided by the invention has the advantages as follows: firstly, the rolling mortar wall fundamentally overcomes the critical defect of incapability of making sand due to the formation of a groove formed by rolling a sand making cavity since the abrasion at the upper part of the rolling mortar wall is small and the abrasion at the lower part of the rolling mortar wall is large due to different abrasion losses, caused by stones with different specifications, to the rolling mortar wall during the sand making process by the rolling mortar wall made of the single material; secondly, the abrasion losses, produced during stone crushing, by Mn13 at the upper part of the rolling mortar wall, is relatively in accordance with the abrasion loss caused by that the lower part of the high-chromium iron rolling mortar wall rolls the sand making cavity, so that the condition of groove formation caused by that the abrasion loss produced when the lower part of a rolling mortar wall made of a single material rolls a sand making cavity during rolling for a sand making process, is larger than the abrasion loss of the upper part of the rolling mortar wall can be avoided.

Owner:ZHEJIANG SHUANGJIN MACHINERY HLDG

Two-component cone sand making machine rolling mortar wall and its production method

The invention relates to a double component rolled mortar wall for a cone sand making machine and a manufacturing method. The double component rolled mortar wall can meet not only the abrasion resistant requirements on broken stone crushing but also the abrasion resistant requirements on rolling sand making when the cone sand making machine is in the sand making process. The upper part of the rolled mortar wall is made of Mn13, the lower part of the rolled mortar wall is made of high-chromium cast iron, and a ring-shaped groove is formed in the outer wall or the inner wall at the lower part of the rolled mortar wall, and is in concave-convex fusion casting coordination with a ring-shaped groove formed in the inner wall or the outer wall at the upper part of the rolled mortar wall. The double component rolled mortar wall has the advantages that 1, the critical defects that in the sand making process on the rolled mortar wall made of a single material, the abrasion losses on the rolled mortar wall by stone materials in different specifications are different, so that the upper part of the rolled mortar wall is slightly abraded while the lower part of the rolled mortar wall is seriously abraded, then a groove is formed in a rolling sand making cavity, and the sand cannot be made, are solved radically; 2, the abrasion loss of the Mn13 at the upper part of the rolled mortar wall when the stone materials are crushed is in relative accordance with the abrasion loss of the rolling sand making cavity at the lower part of the high-chromium cast iron rolled mortar wall.

Owner:ZHEJIANG SHUANGJIN MACHINERY HLDG

A conical sand making machine rolling mortar wall high-frequency vibration pouring mold and casting process

ActiveCN102962398BImprove wear resistanceHigh densityFoundry mouldsFoundry coresHigh densityShock resistance

The invention relates to a high-frequency vibration casting mold of a conical sand maker rolling mortar wall and a casting process capable of achieving the effect of no shrinkage cavity and effectively improving the cast density during casting feeding of the conical sand maker rolling mortar wall. The high-frequency vibration casting mold is characterized in that a sand box is located on a high-frequency vibration platform; the height of a rolling mortar wall forming mold cavity in the sand box is smaller than the height of a casting riser or the volume of the forming mold cavity is smaller than the volume of the casting riser. The casting process comprises the following steps: casting high chromium cast iron into the rolling mortar wall forming mold cavity and the casting riser, then carrying out high-frequency vibration on the high-frequency vibration platform, and cooling to obtain the high chromium cast iron rolling mortar wall with a high density. The high-frequency casting mold and the casting process have the advantages that firstly, the wear resistance of the high chromium cast iron rolling mortar wall is effectively improved, and the sand making cost is greatly reduced; secondly, the feeding effect is good, the cast is high in density, and the occurrence of damage phenomenon is avoided; and thirdly, the wear resistance, the shock resistance and the service life are increased by nearly 5 times, and unexpected technical effects are achieved.

Owner:ZHEJIANG SHUANGJIN MACHINERY HLDG

Cone sand making machine two-component rolling sand making cavity assembly and production method thereof

The invention relates to a cone sand making machine two-component rolling sand making cavity assembly and a production method thereof. According to the invention, the upper part of a rolling mortar wall is made of Mn13, a lower part of the rolling mortar wall is high-carbon chromium steel, an ringed groove is arranged at outer wall or inner wall of the lower part of the rolling mortar wall, and the ringed groove can form concave-convex fusion casting cooperation with a ringed groove on the inner wall or outer wall at upper part of the rolling mortar wall, the upper part of a crushing wall is made of Mn13, a lower part of the crushing wall is made of high-carbon chromium steel, a ringed groove is arranged at outer wall or inner wall of the lower part of the crushing wall, and the ringed groove can form concave-convex fusion cooperation with a ringed groove on the inner wall or outer wall at upper part of the crushing wall. The method has the following advantages that 1)during a sand making process, wear extent of the rolling mortar wall and the crushing wall is different by stone with different specification, defect that a groove is formed on the rolling sand making cavity so that sands can not be produced due to little wearing at upper part of the rolling mortar wall and the crushing wall as well as large wearing at lower part of the rolling mortar wall and the crushing wall can be solved; and 2)wear extent of Mn13 at upper part of the rolling mortar wall and the crushing wall generated during stone crushing is relatively consistent with the wear extent of the rolling sand making cavity at lower part of the high-carbon chromium steel rolling mortar wall.

Owner:ZHEJIANG SHUANGJIN MACHINERY HLDG

Rolling mortar wall and method of conical sand making machine made of mn13 and high chromium cast iron

The invention relates to a rolling mortar wall of a conical sand making machine and a manufacturing method, wherein the rolling mortar wall of the conical sand making machine is made of Mn13 and high-chromium iron, not only can meet the wear-resistant requirement of aggregate crushing , but also can meet the wear-resistant requirement of rolling for sand making during a sand making process, the upper part of a rolling mortar wall is made of Mn13, the lower part of the rolling mortar wall is made of the high-chromium iron, and the upper part of the rolling mortar wall and the lower part of the rolling mortar wall are in concave-convex casting matching. The rolling mortar wall provided by the invention has the advantages as follows: firstly, the rolling mortar wall fundamentally overcomes the critical defect of incapability of making sand due to the formation of a groove formed by rolling a sand making cavity since the abrasion at the upper part of the rolling mortar wall is small and the abrasion at the lower part of the rolling mortar wall is large due to different abrasion losses, caused by stones with different specifications, to the rolling mortar wall during the sand making process by the rolling mortar wall made of the single material; secondly, the abrasion losses, produced during stone crushing, by Mn13 at the upper part of the rolling mortar wall, is relatively in accordance with the abrasion loss caused by that the lower part of the high-chromium iron rolling mortar wall rolls the sand making cavity, so that the condition of groove formation caused by that the abrasion loss produced when the lower part of a rolling mortar wall made of a single material rolls a sand making cavity during rolling for a sand making process, is larger than the abrasion loss of the upper part of the rolling mortar wall can be avoided.

Owner:ZHEJIANG SHUANGJIN MACHINERY HLDG

Rolling mortar wall of conical sand making machine made of high manganese steel and high carbon chromium steel and its manufacturing method

ActiveCN104801384BExtended service lifeReduce manufacturing costGrain treatmentsHigh carbonCrushed stone

The invention relates to a cone sand making machine, which can not only meet the wear-resisting requirements of gravel crushing but also meet the wear-resistant requirements of crushing sand during the sand making process. The cone is composed of high manganese steel and high carbon chromium steel The rolling mortar wall of the sand making machine and its manufacturing method, the upper part of the rolling mortar wall is made of high manganese steel, and the lower part of the rolling mortar wall is made of high carbon chromium steel. Advantages: First, it fundamentally solves the problem that the upper part of the rolling mortar wall wears less and the lower part of the rolling mortar wall wears less due to the different amounts of wear on the rolling mortar wall caused by different specifications of stone materials during the sand making process. The fatal flaw of the sand-pressing chamber is that grooves are formed in the shape of the rolling sand-pressing chamber; the second is that the wear amount of the high-manganese steel on the upper part of the rolling mortar wall when crushed stones is different from that of the high-carbon chromium steel rolling sand-pressing chamber on the lower part of the mortar wall. The amount of wear is relatively consistent, so it fundamentally solves the situation that the groove caused by the wear amount of the lower part of the rolling mortar wall is greater than the wear amount of the upper part of the rolling mortar wall during the sand rolling process of the single material rolling mortar wall.

Owner:ZHEJIANG SHUANGJIN MACHINERY HLDG

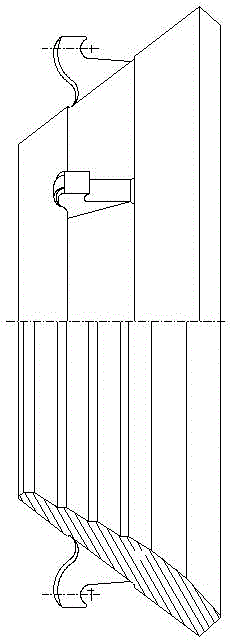

A high-frequency vibration casting mold and casting process for the broken wall of the cone sand making machine

ActiveCN102962399BImprove wear resistanceHigh densityFoundry mouldsFoundry coresHigh densityCasting mold

The invention relates to a high-frequency vibration casting mold of a conical sand maker breaking wall and a casting process capable of achieving the effect of no shrinkage cavity and effectively improving the cast density during casting feeding of the conical sand maker breaking wall. The high-frequency vibration casting mold is characterized in that a sand box is located on a high-frequency vibration platform; and the height of a breaking wall forming mold cavity in the sand box is smaller than the height of a casting riser or the volume of the forming mold cavity is smaller than the volume of the casting riser. The casting process comprises the following steps: casting high chromium cast iron into the breaking wall forming mold cavity and the casting riser, then carrying out high-frequency vibration on the high-frequency vibration platform, and cooling to obtain the high chromium cast iron breaking wall with a high density. The high-frequency vibration casting mold and the casting process have the advantages that firstly, the wear resistance of the high chromium cast iron breaking wall is effectively improved, and the sand making cost is greatly reduced; secondly, the feeding effect is good, the cast is high in density, and the occurrence of damage phenomenon is avoided; and thirdly, the wear resistance, the shock resistance and the service life are increased by nearly 5 times, and unexpected technical effects are achieved.

Owner:ZHEJIANG SHUANGJIN MACHINERY HLDG

A sand making production line

InactiveCN103406185BReduce pollutionTake advantage ofGrain treatmentsWet separationProduction lineEngineering

The invention relates to a production line for producing sand, which comprises a feeding machine, sand producing machines, a sand washer and sedimentation tanks, wherein the number of the sand producing machines is N, and N is an integral number not less than 1; feed inlets are formed in the sand producing machines; the feed inlets comprise stone inlets and water inlets; the feeding machine is respectively connected with the feed inlets of the N sand producing machines; the feed inlets of the N sand producing machines are respectively connected with the sedimentation tanks through pipelines; discharge outlets of the N sand producing machines are respectively connected with the sand washer; the sand washer is connected with the sedimentation tanks through pipelines. According to the invention, a cyclically utilized production line is formed, on one hand, the sand producing efficiency is improved, and the sand producing cost is reduced, and on the other hand, noise, dust and sewage pollution during the sand producing process are reduced, various intermediate products are enabled to be fully utilized, and the requirements of the present market are satisfied.

Owner:李小福

Rolling sand chamber assembly and method of cone sand making machine with diameter less than 2000mm

The invention relates to a conical sand making machine with a diameter of less than 2000mm which can meet the wear resistance requirements of crushed stone and the wear resistance requirements of rolling sand during the sand making process. The assembly and the manufacturing method include a rolling mortar wall and a crushing wall, the upper part of the rolling mortar wall is made of Mn13, the lower part of the rolling mortar wall is made of high-chromium cast iron; the upper part of the broken wall is made of Mn13, and the lower part of the broken wall is made of high-chromium cast iron. Advantages: First, in the sand making process of single material rolling mortar wall and crushing wall, due to the different wear of different specifications of stone on the rolling mortar wall and crushing wall, the wear of the rolling mortar wall and the upper part of the crushing wall is small, The fatal defect of rolling sand cavity to form grooves and unable to make sand due to the large wear of the lower part; the second is that the wear amount of Mn13 on the upper part of the rolling mortar wall and the crushing wall in the crushed stone is the same as that of the high chromium cast iron in the lower part of the rolling mortar wall. The wear amount of the crushed sand cavity is relatively consistent, which greatly prolongs the service life of the rolling mortar wall and the crushing wall.

Owner:ZHEJIANG SHUANGJIN MACHINERY HLDG

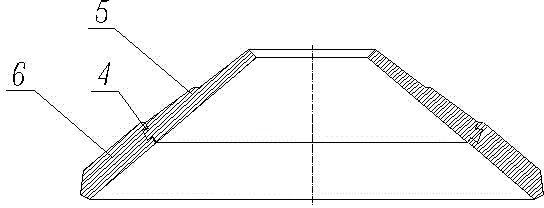

Crushing wall of cone sand making machine composed of high manganese steel and high carbon chromium steel and production method

ActiveCN104801371BExtended service lifeReduce manufacturing costGrain treatmentsHigh carbonWear resistant

The invention relates to a crushing wall of a conical sand making machine and a manufacturing method, wherein the crushing wall of the conical sand making machine is made of high manganese steel and high-carbon chromium steel, not only can meet the wear-resistant requirement of aggregate crushing, but also meets the wear-resistant requirement of rolling for sand making during a sand making process, the upper part of the crushing wall is made of the high manganese steel and the lower part of the crushing wall is made of the high-carbon chromium steel. The crushing wall provided by the invention has the advantages as follows: firstly, the crushing wall of the conical sand making machine fundamentally overcomes the critical defect of incapability of making sand due to the formation of a groove in a rolling sand making cavity, caused by small abrasion at the upper part of the crushing wall and the large abrasion at the lower part of the crushing wall since abrasion losses, caused by stones with different specifications, to the crushing wall are different during a sand making process by the crushing wall made of the single material; secondly, the abrasion loss of the high manganese steel at the upper part of the crushing wall is relatively in accordance with the abrasion loss caused by that the lower part of the high-carbon chromium steel crushing wall rolls the sand making cavity.

Owner:ZHEJIANG SHUANGJIN MACHINERY HLDG

Sand making technology of sandstone

The invention relates to a sand making technology of sandstone, which comprises the steps of taking a material, breaking, screening, and performing stone and powder separation, wherein in the step of taking the material, limestone with the particle size below 50mm is selected; in the step of breaking, the limestone with the particle size below 50mm is put in a sand making machine, and clear water with the volume more than three times that of the limestone is added, mixed and smashed; in the step of screening, a smashed mixture is put in a screening machine for screening treatment; and in the step of the stone and powder separation, the screened mixture is subjected to water washing to form finished sand. According to the sand making technology, the high-quality artificial sand is manufactured; hardware consumption in a sand making process is reduced greatly; the sand making efficiency is improved; the sand making cost is lowered; noise and dust pollution in the sand making process are reduced; and a requirement of a market at present is met.

Owner:李小福

Two-component crushing wall and method of cone sand making machine with diameter less than 2000mm

The invention relates to a cone sand maker two-component crushing wall being smaller than 2000 mm in diameter and a manufacturing method, and aims to meet not only the abrasion-resistant requirement of stone crushing but also the abrasion-resistant requirement of rolling-based sand making during a sand making process. The upper part and the lower part of the cone sand maker two-component crushing wall are made of high manganese steel and high-carbon chromium steel respectively. The cone sand maker two-component crushing wall has the following advantages: (1) the fatal defect that sand making cannot be performed during the sand making process because a single material rolling mortar wall suffers different abrasion losses from different sized stones, the upper part of the single material rolling mortar wall is slightly abraded while the lower part thereof is seriously abraded, and a groove is formed in a rolling-based sand making cavity can be fundamentally overcome; (2) the abrasion loss caused by high manganese steel at the upper part of the cone sand maker two-component crushing wall during the stone crushing process is relatively consistent with that of the rolling-based sand making cavity in the high-carbon chromium steel lower part of the cone sand maker two-component crushing wall.

Owner:ZHEJIANG SHUANGJIN MACHINERY HLDG

Cone sand maker rolling-based sand making cavity assembly being smaller than 2000 mm in diameter and manufacturing method

The invention relates to a cone sand maker rolling-based sand making cavity assembly being smaller than 2000 mm in diameter and a manufacturing method, and aims to meet not only the abrasion-resistant requirement of stone crushing but also the abrasion-resistant requirement of rolling-based sand making during a sand making process. The cone sand maker rolling-based sand making cavity assembly comprises a rolling mortar wall and a crushing wall, wherein the upper parts of the rolling mortar wall and the crushing wall are made of Mn13, and the lower parts thereof are made of high-chromium iron. The cone sand maker rolling-based sand making cavity assembly has the following advantages: (1) the fatal defect that sand making cannot be performed during the sand making process because the single material rolling mortar wall and a single material crushing wall suffer different abrasion losses from different sized stones, the upper parts of the single material rolling mortar wall and the single material crushing wall are slightly abraded while the lower parts thereof are seriously abraded, and a groove is formed in a rolling-based sand making cavity can be overcome; (2) the abrasion loss caused by Mn13 at the upper parts of the rolling mortar wall and the crushing wall during the stone crushing process is relatively consistent with that of the rolling-based sand making cavity in the high-chromium iron lower part of the rolling mortar wall, so that the service lives of the rolling mortar wall and the crushing wall are greatly prolonged.

Owner:ZHEJIANG SHUANGJIN MACHINERY HLDG

Two-component rolling mortar wall and method for conical sand making machine with diameter less than 2000mm

ActiveCN104801374BExtended service lifeReduce manufacturing costGrain treatmentsCrushed stoneWear resistance

The invention relates to a conical sand making machine with a diameter of less than 2000mm and a two-component rolling cone sand making machine which can meet the wear-resistant requirements for crushing crushed stones and meet the wear-resistant requirements for crushing sand during the sand making process. The mortar wall and its manufacturing method are as follows: the upper part of the rolled mortar wall is made of high manganese steel, and the lower part of the rolled mortar wall is made of high carbon chromium steel. Advantages: First, it fundamentally solves the problem that the upper part of the rolling mortar wall wears less and the lower part of the rolling mortar wall wears less due to different specifications of stones on the rolling mortar wall during the sand making process. The fatal flaw of the sand-pressing chamber is that grooves are formed in the shape of the rolling-pressed sand chamber; the second is that the wear amount of the high-manganese steel on the upper part of the rolling mortar wall when crushing stones is different from that of the high-carbon chromium steel rolling-mortar wall on the lower part of the sand-pressing chamber. The amount of wear is relatively consistent, so it fundamentally solves the situation that the groove caused by the wear amount of the lower part of the rolling mortar wall is greater than the wear amount of the upper part of the rolling mortar wall during the sand rolling process of the single material rolling mortar wall.

Owner:ZHEJIANG SHUANGJIN MACHINERY HLDG

Rolling sand chamber assembly and manufacturing method of two-component cone sand making machine

ActiveCN104801380BExtended service lifeReduce use costGrain treatmentsMechanical engineeringMaterials science

Owner:ZHEJIANG SHUANGJIN MACHINERY HLDG

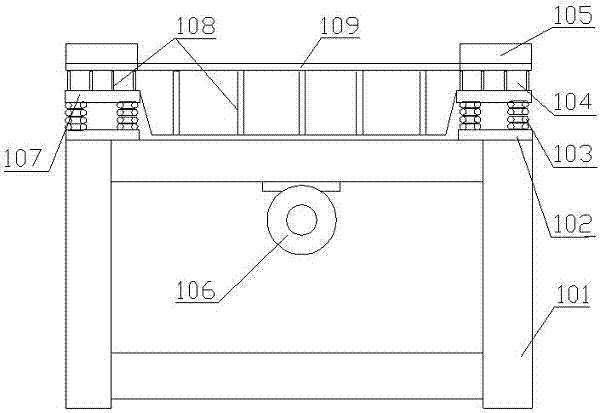

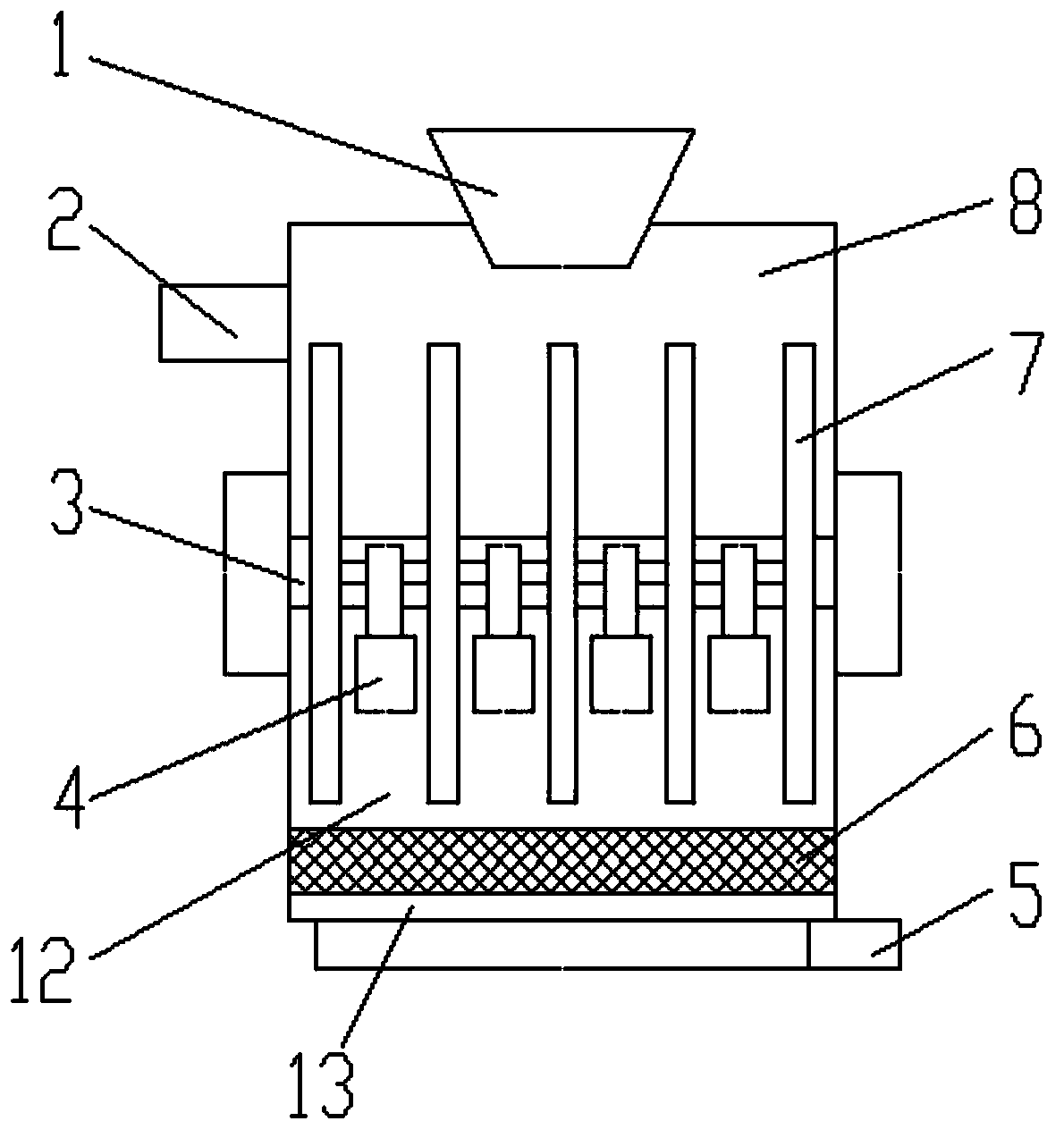

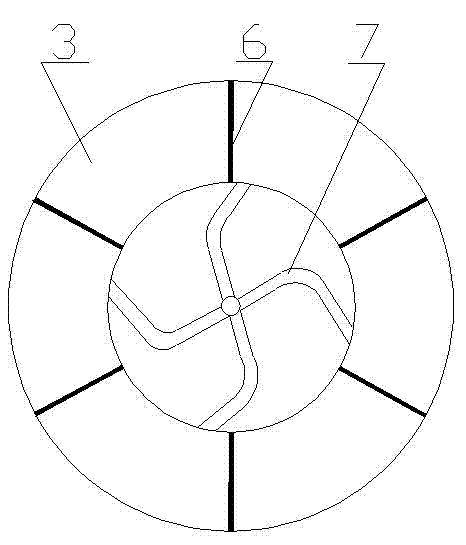

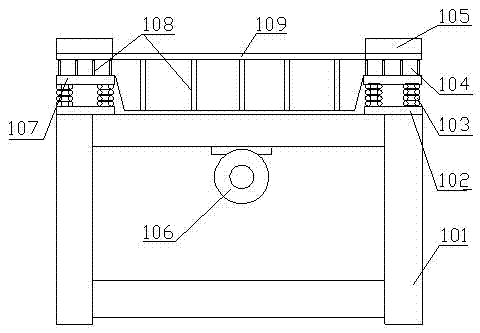

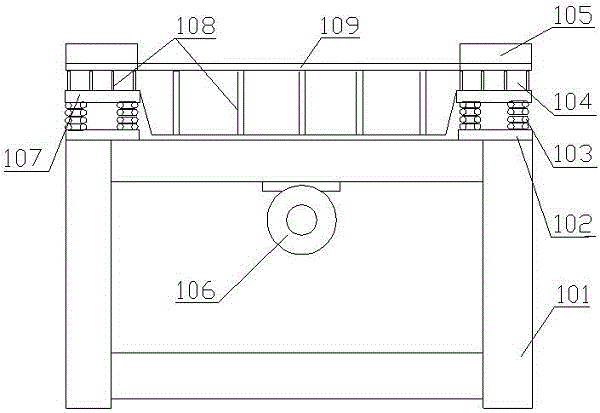

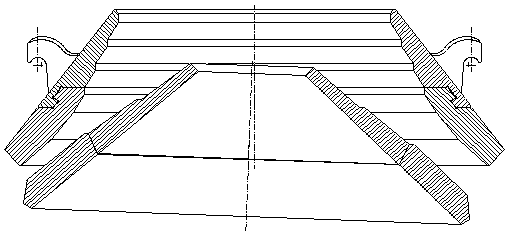

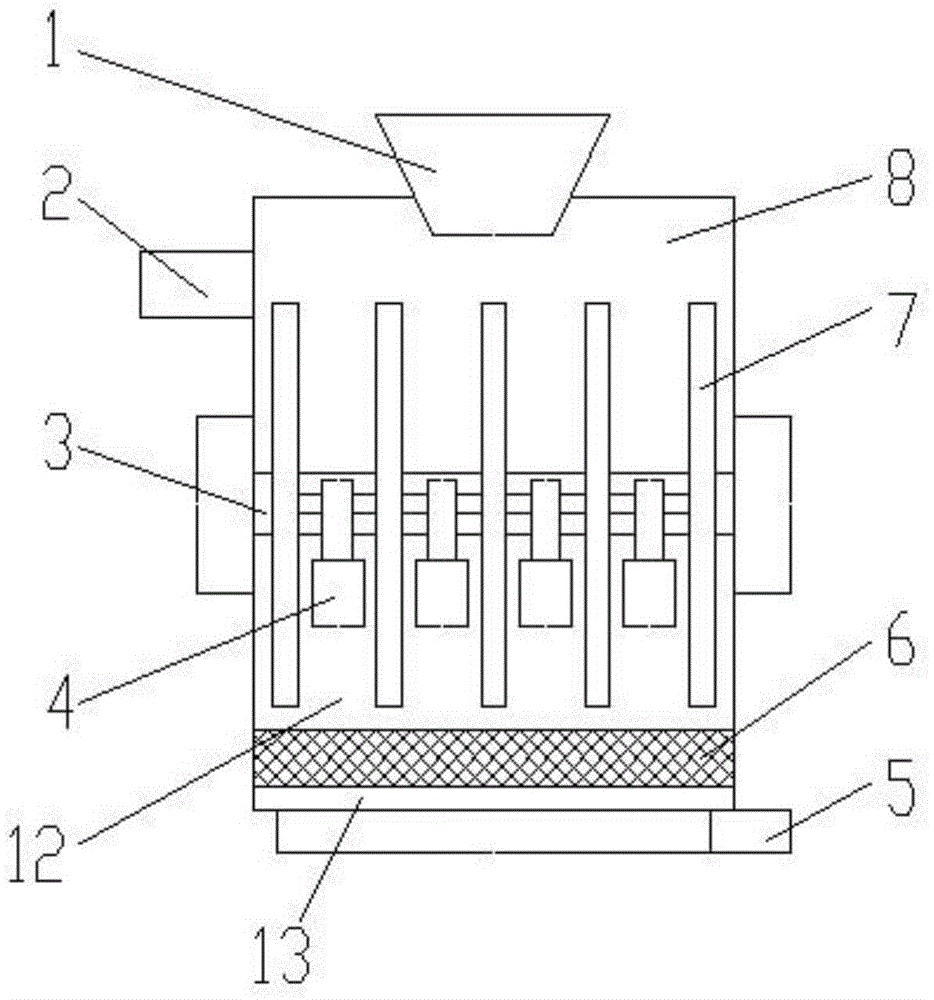

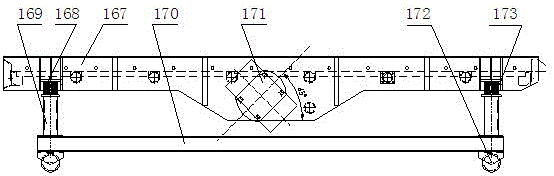

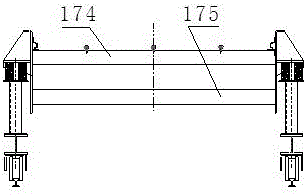

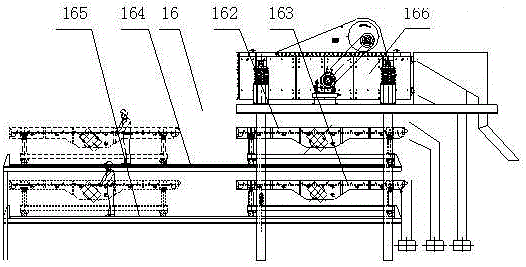

Special mobile linear vibrating screen and method for dry sand production line

ActiveCN104549999BImprove sand passing efficiencyQuick launchSievingScreeningProduction lineDry sand

The invention relates to a movable linear vibrating screen and a vibratory sand screening movement method special for a dry sand making production line, which can guarantee that a screen in the linear vibrating screen has an exciting sand screening function and also has a trace front-back movement sand screening function. The movable linear vibrating screen comprises an upper movable linear vibrating screen and a lower movable linear vibrating screen with same structures which are distributed up and down and are positioned on an upper linear vibrating screen guide rail and a lower linear vibrating screen guide rail respectively, wherein an exciting motor in the upper movable linear vibrating screen is arranged on the middle part of a screen box; four corners of the back face of the screen box are provided with grooves; the grooves in the four corners of the back face of the screen box are matched with upper end faces of supporting legs through elastic cushions respectively and are used for supporting the screen box; the lower ends of the supporting legs are connected with the upper end faces of I steel bars; the lower ends of the I steel bars are provided with track wheels; the track wheels are positioned on the linear vibrating screen guide rails; an upper layer screen plate assembly and a lower layer screen plate assembly are positioned on the upper part and the lower part on the inner side of the screen box respectively.

Owner:ZHEJIANG SHUANGJIN MACHINERY HLDG

Rolling cavity assembly of conical sand making machine, made of Mn13 and high-carbon chromium steel, and method

The invention relates to a rolling cavity assembly of a conical sand making machine and a manufacturing method, wherein the rolling cavity assembly of the conical sand making machine is made of Mn13 and high-carbon chromium steel, not only can meet the wear-resistant requirement of aggregate crushing, but also can meet the wear-resistant requirement of rolling for sand making during a sand making process, the upper part of a rolling mortar wall is made of Mn13, the lower part of the rolling mortar wall is made of the high-carbon chromium steel, and the upper part of the rolling mortar wall and the lower part of the rolling mortar wall are in concave-convex casting matching; the upper part of a crushing wall is made of the Mn13 and the lower part of the crushing wall is made of the high-carbon chromium steel, and the upper part of the crushing wall and the lower part of the crushing wall are in concave-convex casting matching. The rolling cavity assembly provided by the invention has the advantages as follows: firstly, the rolling cavity assembly overcomes the critical defect of incapability of making sand due to the formation of a groove formed by rolling a sand making cavity since the abrasion at the upper part of the rolling mortar wall and the crushing wall is small and the abrasion at the lower part of the rolling mortar wall and the crushing wall is large due to different abrasion losses, caused by stones with different specifications to the crushing wall during the sand making process by the rolling mortar wall and the crushing wall made of the single material ; secondly, the abrasion losses, produced during stone crushing, by Mn13 at the upper parts of the rolling mortar wall and the crushing wall, is relatively in accordance with the abrasion loss caused by that the lower part of the high-carbon chromium steel rolling mortar wall rolls the sand making cavity.

Owner:ZHEJIANG SHUANGJIN MACHINERY HLDG

Rolling cavity assembly and method of conical sand making machine composed of mn13 and high carbon chromium steel

Owner:ZHEJIANG SHUANGJIN MACHINERY HLDG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com