Cone sand making machine two-component rolling sand making cavity assembly and production method thereof

A conical sand making machine, two-component technology, applied in the direction of grain processing, etc., can solve the problems of small wear state, scrapping of the wall of the rolling mortar, and serious wear, so as to prolong the service life, reduce the cost of sand making, and reduce the use cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

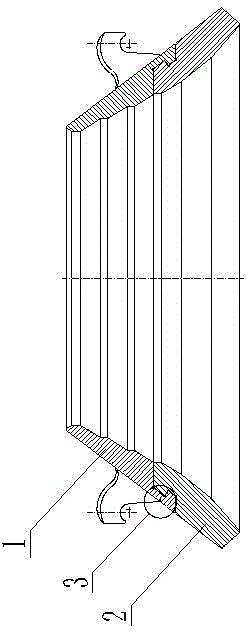

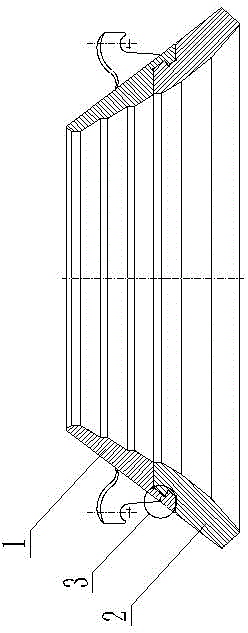

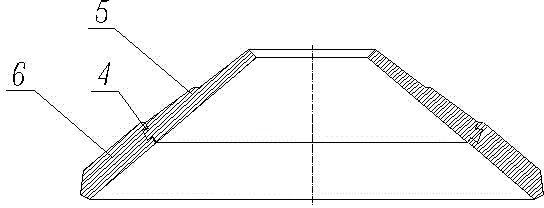

[0014] Embodiment 1: with reference to attached Figure 1-3 . A two-component rolling sand chamber assembly for a conical sand making machine, the upper part 1 of the rolling mortar wall is made of Mn13, the lower part 2 of the rolling mortar wall is made of high-carbon chromium steel, and there is an annular groove on the outer or inner wall of the lower part of the rolling mortar wall and is connected with the The annular groove on the inner or outer wall of the upper part of the rolling mortar wall forms a concave-convex casting fit 3; the upper part 5 of the crushing wall is Mn13, the lower part 6 of the crushing wall is high-carbon chromium steel, and there is an annular groove on the outer or inner wall of the lower part of the crushing wall and is connected with the upper part of the crushing wall The annular groove on the inner wall or the outer wall forms a concavo-convex casting fit 4 . A trumpet-shaped casting runner is arranged along the upper groove of the annula...

Embodiment 2

[0015] Example 2: On the basis of Example 1, a method for manufacturing a two-component rolling sand chamber assembly of a conical sand making machine, making the wall of the rolling mortar: (1) Making the casting mold for the lower part of the wall of the rolling mortar according to conventional techniques And there are grooves on the outer wall or inner wall of the lower mold of the rolling mortar wall casting mold to form a clamping mold. The lower mold of the lower casting mold of the rolling mortar wall is placed on a high-frequency vibration platform, and the molten material is melted under the vibration of the high-frequency vibration platform. The high carbon chromium steel is cast into the casting mold of the lower part of the rolling mortar wall, and the lower part of the rolling mortar wall is obtained after cooling and forming, and then the lower part of the rolling mortar wall is heat treated; (2) The groove clamping part of the lower part of the rolling mortar wall...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com