Special mobile linear vibrating screen and method for dry sand production line

A linear vibrating sieve, mobile technology, applied to chemical instruments and methods, filter screens, solid separation, etc., can solve problems such as the inability to use linear vibrating sieves, reduce sand making costs, improve sand passing efficiency, and save labor for replacement Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

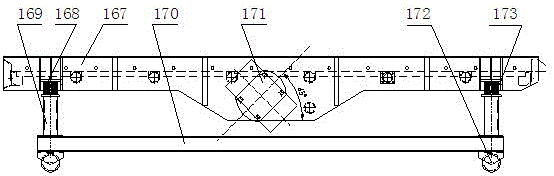

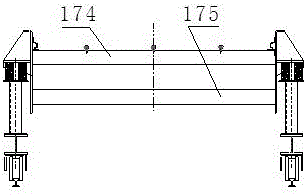

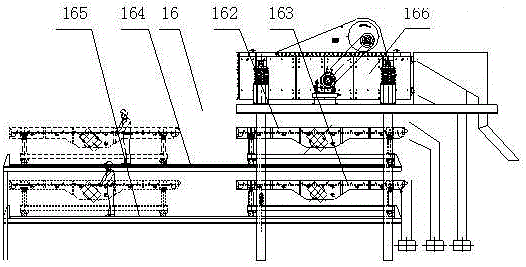

[0011] Embodiment 1: with reference to attached Figure 1-3 . A mobile linear vibrating screen dedicated to a dry sand production line. The mobile linear vibrating screen 4 consists of an upper moving linear vibrating screen 162 and a lower moving linear vibrating screen 163 with the same structure. On the guide rail 165 of the lower linear vibrating screen; the excitation motor 171 in the upper movable linear vibrating screen 162 is installed in the middle of the screen box 167, the four corners of the back of the screen box 167 are provided with grooves 173, and the grooves at the four corners of the back of the screen box 167 are respectively passed through elastic Pad 168 cooperates with the upper end surface of supporting leg 169 and is used to support screen box 167. The lower end of supporting leg 169 is connected with the upper end surface of I-shaped steel bar 170. The lower end of I-shaped steel bar 170 is equipped with track wheel 172. On the guide rails 164 and 16...

Embodiment 2

[0012] Embodiment 2: On the basis of Embodiment 1, a vibration method of a special mobile linear vibrating screen for a dry sand making production line, in the mobile linear vibrating screen 162, under the action of the excitation motor 171, the screen mesh is excited and vibrated At the same time, the mobile linear vibrating screen performs a small amount of sand screening movement back and forth on the guide rail.

Embodiment 3

[0013] Embodiment 3: On the basis of Embodiment 2, a vibration method of a special mobile linear vibrating screen for a dry sand making production line, a multi-layer mobile vibrating linear screen is provided below the fixed linear vibrating screen 166, and a multi-layer mobile linear vibrating screen is provided. In the vibrating screen 162, under the action of the vibrating motor 171, the screen mesh is vibrated and vibrated, and at the same time, the mobile linear vibrating screen performs a small amount of sand sieving movement back and forth on the guide rail.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com