Machine-made sand production station and sand making method

A technology of machine-made sand and sand-making machine, applied in the field of sand-making equipment, can solve the problems that the ratio of machine-made sand and gravel powder is not easy to control, cannot meet the requirements of high-performance concrete, and the ultra-fine powder is not easy to remove, etc., so as to reduce equipment power consumption and save equipment. Investment cost, compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The following will clearly and completely describe the technical solutions in the embodiments of the present invention in conjunction with the accompanying drawings in the embodiments of the present invention:

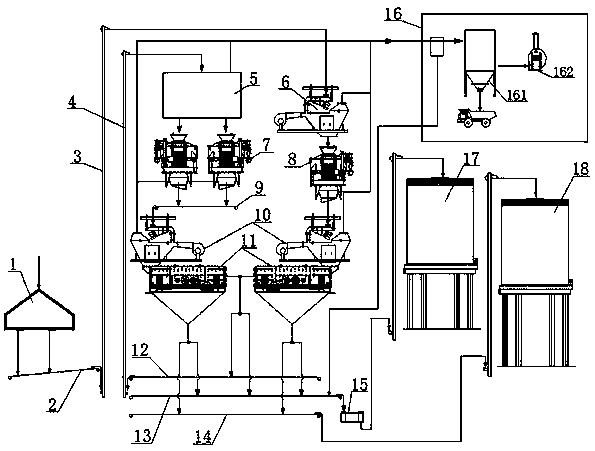

[0027] Such as figure 1 As shown, a machine-made sand production building station includes a multi-layer vertically arranged steel structure frame, and a dedusting machine (including a primary dedusting machine 6 and a secondary dedusting machine 10 ), a sand making machine machine 7, shaping machine 8, screening machine 11, dedusting equipment 16 and humidifier 15. The layout of the equipment is as follows: a material bin and a vibrating feeder 1 are arranged on the ground on one side of the steel structure frame, and a material buffer bin is arranged on the top floor 5. Sand making machine 7, first-level powder removing machine 6 and shaping machine 8, the bottom layer is equipped with screening machine 11, humidifier 15 and multiple belt conveyors, and a No. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com