Conical sand making machine rolling cavity assembly and method composed of mn13 and high chromium cast iron

A technology of cone sand making machine and high-chromium cast iron, which is applied to grain processing and other directions, can solve the problems of small wear state, scrapped rolling mortar wall, and very serious wear, so as to reduce the cost of sand making, reduce the cost of use, and prolong the use. effect of life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

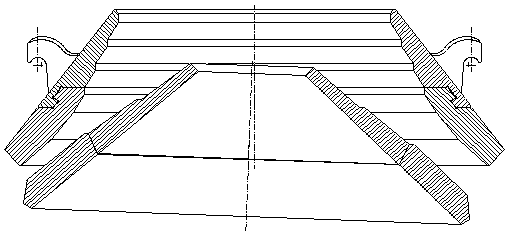

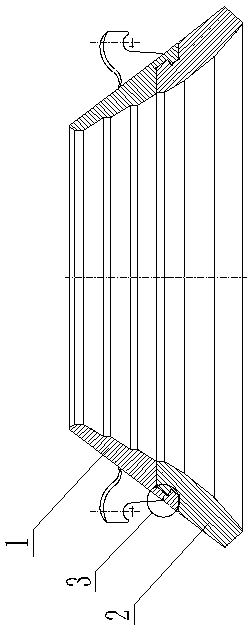

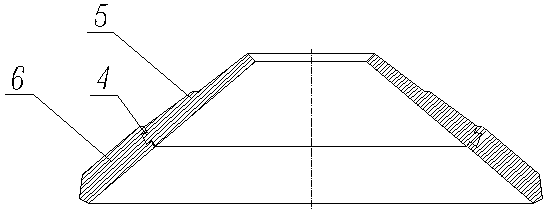

[0014] Embodiment 1: with reference to attached Figure 1-3 . A conical sand making machine rolling cavity assembly composed of Mn13 and high chromium cast iron, the upper part 1 of the rolling mortar wall is Mn13, the lower part 2 of the rolling mortar wall is high chromium cast iron, and the upper part of the rolling mortar wall and the lower part of the rolling mortar wall are concave and convex fusion casting Coordination 3; the upper part 5 of the crushing wall is Mn13, the lower part 6 of the crushing wall is high chromium cast iron, and the upper part of the crushing wall and the lower part of the crushing wall are concave-convex casting fit 4. The height of Mn13 rolling wall is greater than that of high chromium cast iron; the height of Mn13 crushing wall is greater than that of high chromium cast iron. The material of the Mn13 rolling wall is ZGMn13-1, ZGMn13-2, ZGMn13-3, ZGMn13-4, ZGMn13-5; the material of the Mn13 broken wall is ZGMn13-1, ZGMn13-2, ZGMn13-3, ZGMn13...

Embodiment 2

[0015] Example 2: On the basis of Example 1, the lower end surface of the Mn13 rolling mortar wall and the upper end surface of the high-chromium cast iron rolling mortar wall are in a concave-convex fusion casting fit; the lower end surface of the Mn13 crushing wall is in a concave-convex casting fit with the upper end surface of the high-chromium cast iron crushing wall. The lower end surface of the Mn13 rolling mortar wall is an annular boss and the section of the annular boss is a trapezoidal structure with a wide bottom and a narrow top. Matches with the annular boss on the lower end of the Mn13 rolling mortar wall; the lower end of the Mn13 crushing wall is an annular boss and the cross-section of the annular boss is a trapezoidal structure with a wide bottom and a narrow top. The cross section of the groove is a trapezoidal structure with a wide bottom and a narrow top and matches with the annular boss on the lower end surface of the Mn13 broken wall.

Embodiment 3

[0016] Example 3: On the basis of Example 1, the lower end surface of the Mn13 rolling mortar wall is an annular groove and the annular concave section is a trapezoidal structure with a wide top and a narrow bottom. The cross-section of the table is a trapezoidal structure with a wide top and a narrow bottom and matches the annular groove on the lower end of the Mn13 rolling mortar wall; the lower end of the Mn13 crushing wall is a circular groove and the annular concave section is a trapezoidal structure with a wide top and a narrow bottom, high chromium cast iron The upper end surface of the crushing wall is an annular boss and the section of the annular boss is a trapezoidal structure with a wide top and a narrow bottom, which matches the annular groove on the lower end surface of the Mn13 crushing wall.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com