Casting mold of conical sand maker rolling mortar wall and casting process

A conical sand making machine and casting process technology, which is applied in the direction of manufacturing tools, casting molding equipment, casting molds, etc., can solve the problems of high crushing cost, poor feeding effect, and poor casting density, so as to avoid damage Phenomenon, good feeding effect, and improved impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

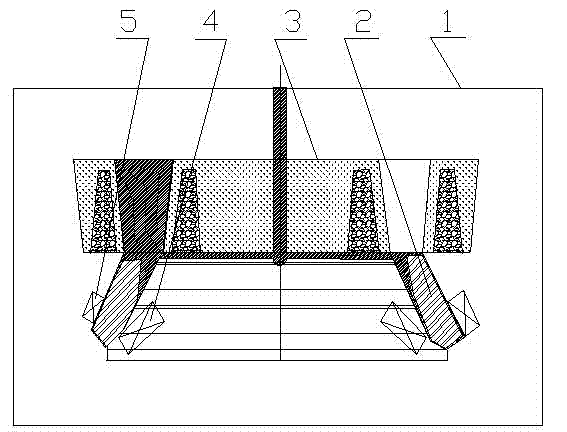

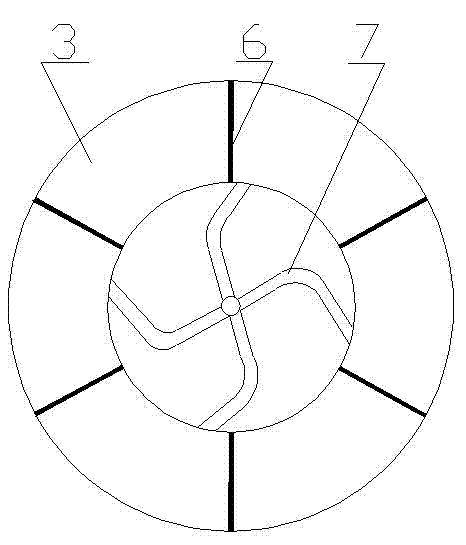

[0016] Embodiment 1: with reference to attached Figure 1-3 . A conical sand making machine rolling mortar wall pouring mold casting process, the height of the molding cavity 2 of the rolling mortar wall in the sand box 1 is smaller than the height of the pouring riser 3 or the volume of the molding cavity 2 is smaller than the volume of the pouring riser 3, or the height The weight of the chromium cast iron rolling wall is less than the weight of the pouring riser. The high chromium cast iron is poured into the rolling wall molding cavity 2 and the pouring riser 3, and then the sand box 1 is hoisted on the high-frequency vibration platform for high-frequency vibration. After vibration and cooling, a high-density high-chromium cast iron rolling mortar wall can be obtained. The inner wall and the outer wall of the mold cavity 2 of the rolling mortar wall are equipped with a plurality of built-in cold irons 4 and external cold irons 5, and the cold irons 4 and 5 are evenly dist...

Embodiment 2

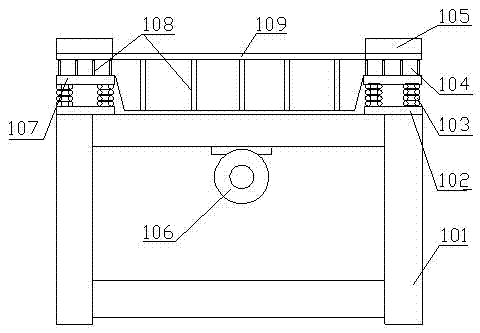

[0017] Embodiment 2: with reference to attached image 3 . A high-frequency vibration platform for the casting mold of the rolling mortar wall of the conical sand making machine. One or more compression springs 103 are respectively placed at the four corners of the rectangular support 101, and the pressure-bearing vibration platform 104 is placed on the compression springs 103. 105 is located in the middle of the back of the pressure-bearing vibration platform 104 and drives the pressure-bearing vibration platform to vibrate at high frequency. A pressing plate 102 is disposed on the lower end surface of the compression spring 103 . Angular baffles 105 are provided at the four corners of the platform surface of the pressure-bearing vibration platform 104 . The pressure-bearing vibration platform 104 is composed of a platen 109, a vertical plate 108 and a four-corner spring top plate 107. The vertical plate 108 is vertically welded on the back of the platen 109, and the four-c...

Embodiment 3

[0018] Embodiment 3: with reference to attached figure 1 . A casting mold for the rolling mortar wall of a conical sand making machine, comprising a sand box 1, the height of the molding cavity 2 of the rolling mortar wall in the sand box 1 is smaller than the height of the pouring riser 3 or the volume of the molding cavity 2 is smaller than the volume of the pouring riser 3, and the pouring A circle of the riser 3 is provided with a plurality of riser spacers 6 . The inner and outer walls of the mold cavity 2 for rolling the wall are provided with a plurality of built-in cold irons 4 and external cold irons 5 . The pouring riser 3 is provided with a plurality of runners 7 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com