Electromagnetic shielding yarn with metal wire wrapped elastic yarn, production equipment and production method thereof

A technology for electromagnetic shielding and production equipment, which is applied in the direction of continuous winding spinning machine, yarn, spinning machine, etc., can solve the problems of poor contact comfort, poor comfort, tingling feeling, etc. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

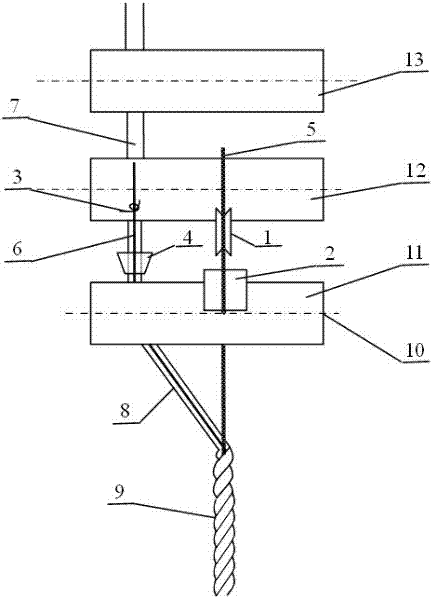

[0023] Embodiment 1: the production equipment of electromagnetic shielding yarn:

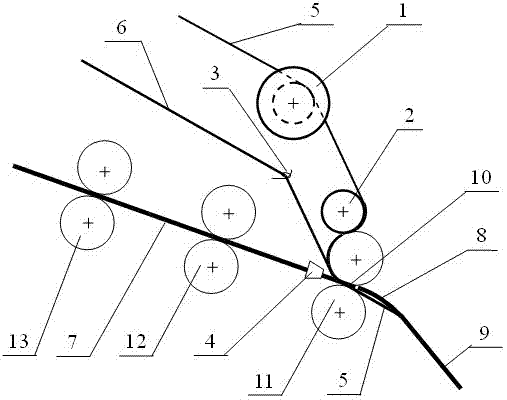

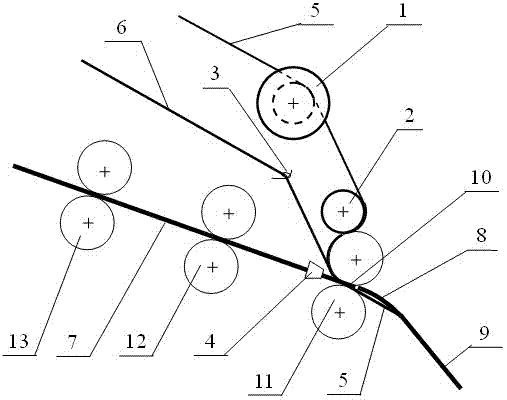

[0024] Such as figure 1 As shown, it is a top view of the production equipment of electromagnetic shielding yarn, figure 2 In its side view, the electromagnetic shielding yarn production equipment includes a ring spinning frame, and also includes a tension wheel 1 , a holding roller 2 , a yarn guide hook 3 and a cluster 4 . The grip roller 2 is in contact with the front roller 11 of the ring spinning frame, and is driven by the rotation of the front roller 11 . The tension wheel 1 is installed on the ring spinning frame at a position above the holding roller 2, and the yarn guide hook 3 and the bundler 4 are located behind the front roller nip 10 of the ring spinning frame.

[0025] When in use, take an elastic filament tube, pass the elastic filament 5 on it through the tension wheel 1 with a certain tension, and then directly pass the holding roller 2 with a certain angle of envelopment o...

Embodiment 2~7

[0026] Embodiment 2~7: Electromagnetic shielding yarn and production method thereof:

[0027]Adopt the production equipment of the electromagnetic shielding yarn described in embodiment 1, the staple fiber strip 7 is fed into the front roller nip 10 through the bundler 4, and the metal wire 6 is fed into the front roller nip 10 through the yarn guide hook 3, so that The metal wire 6 described above is located on the central axis of the short fiber strand 7, and the short fiber strand 7 and the metal wire 6 are combined on the outside of the front roller jaw 10 to form a covered yarn segment that the short fiber strand 7 coats the metal wire 6 8. After the elastic yarn 5 passes through the tension wheel 1 and the holding roller 2, it is attached to the front roller 11 and fed into the front roller nip 10, and the covered yarn segment 8 and the elastic yarn 5 exiting the front roller nip 10 are twisted Under the action, the electromagnetic shielding yarn in which the covering ...

Embodiment 2

[0033] One stainless steel wire tube, one spandex filament cake and one cotton short fiber roving tube are used, and the three-axis composite spinning is carried out according to the above composite spinning method. The specific process parameters are shown in the table below. The electromagnetic shielding yarn of the spun cotton fiber coated stainless steel wire and then outsourced spandex yarn, its covering rate, twist angle characteristics, electrical insulation, comfort and elasticity are listed in Table 1. This demonstrates the fact that the surface rigid fibers are transformed into elastic yarns.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com