Gas atomization powder production equipment and powder production method thereof

A pulverizing equipment and gas atomization technology, which are applied in the field of metal powder manufacturing, can solve the problems of high consumption of atomized gas flow, increase the cost and high cost of gas atomized metal powder, and achieve the improvement of quality, utilization rate and production efficiency. , the effect of reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

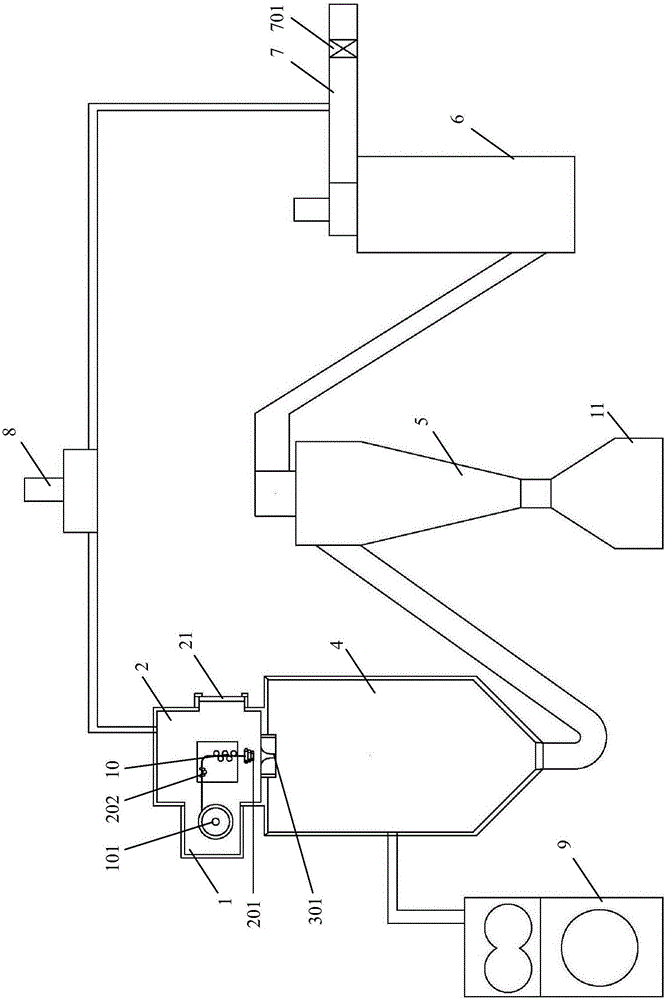

[0050] like figure 1 As shown, a gas atomization powder making equipment includes a raw material bin 1 , a melting chamber 2 , an atomizer, an atomization tower 4 , a cyclone separator 5 , and a vacuum system 9 . Wherein, the raw material bin 1 is a vacuum-sealed structure, and a rotating bracket 101 for placing a metal wire tray is arranged therein. The smelting chamber 2 communicates with the raw material bin 1 and is integrated with the raw material bin 1, and the two are sealed and isolated from the outside world. The melting chamber 2 is a vacuum-sealed double-layer water-cooled structure, with an observation window 21 on the side to monitor the melting and atomization process. The observation window 21 is preferably made of quartz glass and can be equipped with a movable shading plate.

[0051]The melting chamber 2 is provided with an induction coil 201 and a wire feeder 202 that guides the wire on the rotating bracket into the upper center of the induction coil 201. In...

Embodiment 2

[0064] like figure 1 As shown, a gas atomization powder making equipment includes a raw material bin 1, a smelting chamber 2, an atomizer, an atomization tower 4, a cyclone separator 5, a tail filter 6, an exhaust pipe 7, and an internal circulation fan 8 and vacuum system9. Wherein, the raw material bin 1 is a vacuum-sealed structure, and a rotating bracket 101 for placing a metal wire tray is arranged therein. The smelting chamber 2 communicates with the raw material bin 1 and is integrated with the raw material bin 1, and the two are sealed and isolated from the outside world. The melting chamber 2 is a vacuum-sealed double-layer water-cooled structure, with an observation window 21 on the side to monitor the melting and atomization process. The observation window 21 is preferably made of quartz glass and can be equipped with a movable shading plate.

[0065] The melting chamber 2 is provided with an induction coil 201 and a wire feeder 202 that guides the wire on the rot...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com