Apparatus and methods for the production of powders

An equipment and powder technology, which is used in the production of ultra-fine powder, also known as nano-powder, in the field of explosion and discharge, and can solve the problems of unbalanced lattice and high quenching speed of pure metal.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

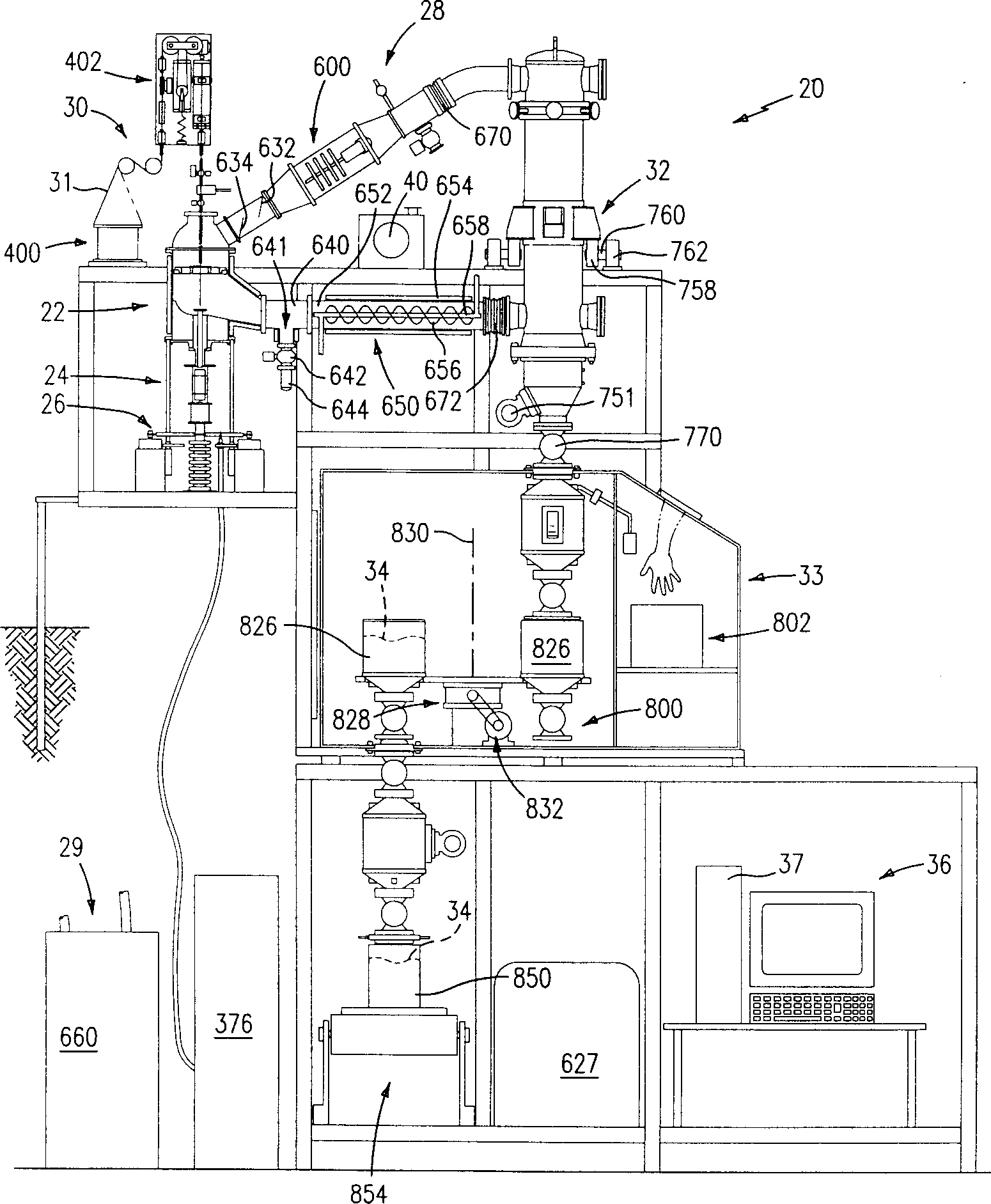

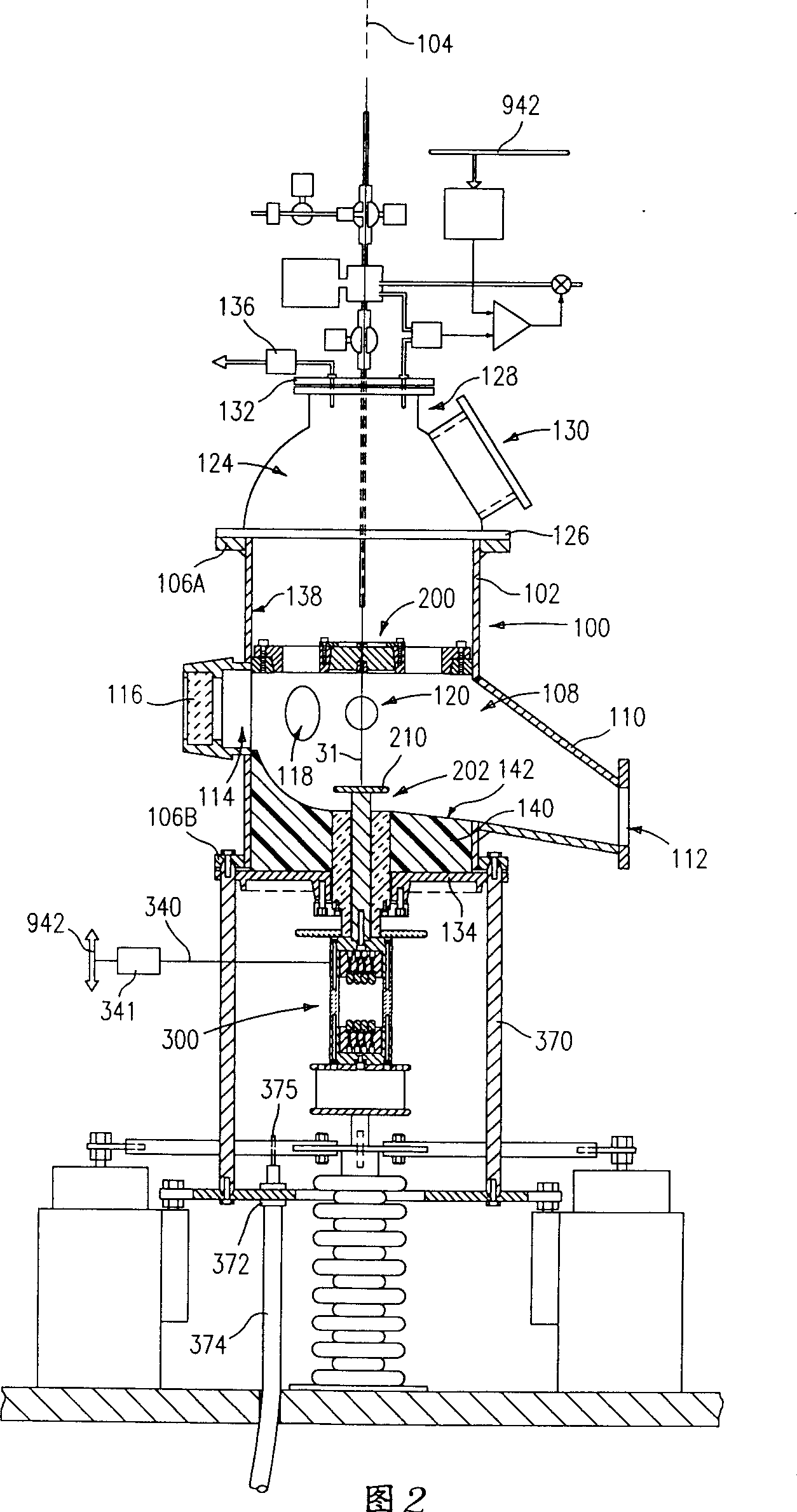

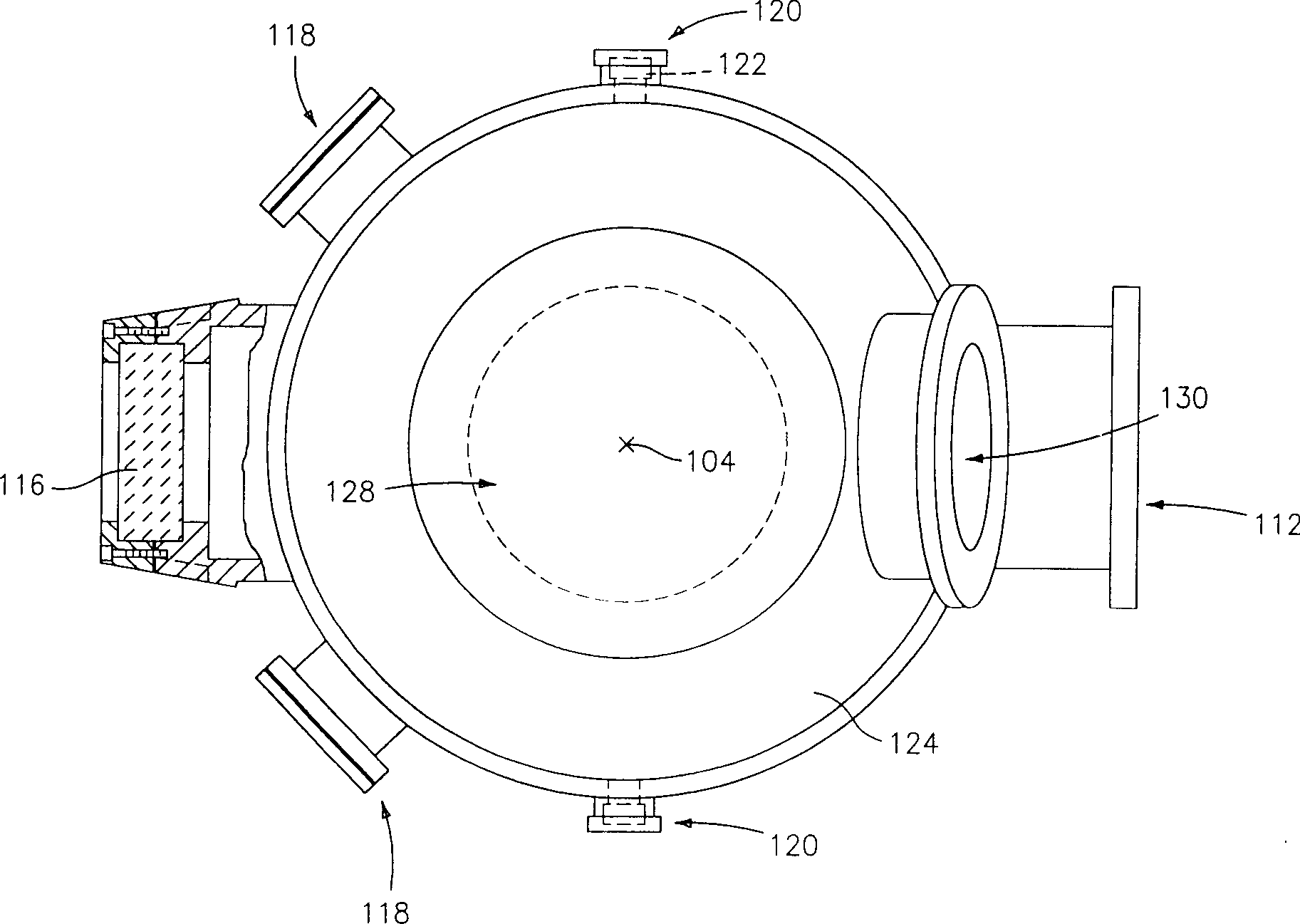

[0050] The present invention provides an improved method and method for the production of ultrafine metal powders, or equivalently metal oxides, metal nitrides, metal carbides and other compounds which can be produced by the reaction of a dense metal plasma with the surrounding (bath) gas equipment. Provides high voltage, high current, pulsed power to efficiently deliver large amounts of electrical energy to the wire. Preferably, the energy delivered is substantially in excess of that required to vaporize the metal (eg, by a factor of about 1.1 to about 3 in preferred embodiments), resulting in a condition known as "superheating." Energy is delivered for a short enough time (eg, a few microseconds in a preferred embodiment) to ensure that the wire bursts apart rather than simply vaporizing.

[0051] For example, with 26AWG (0.404mm diameter) aluminum wire stock (e.g. Alloy 1188 (minimum 99.88% purity), tempered to H-18 (very soft)) blasted in 10 inch (25cm) lengths, applicabl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com