Supercritical hydro extraction of kerogen and aqueous extraction of alumina and soda ash with a residue for portland cement production

A technology for kerogen and residues, which is applied in the fields of supercritical water extraction of kerogen and water extraction of alumina and soda ash and residues used for Portland cement preparation, can solve problems such as low oil yield and the like, and achieves The effect of reducing environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

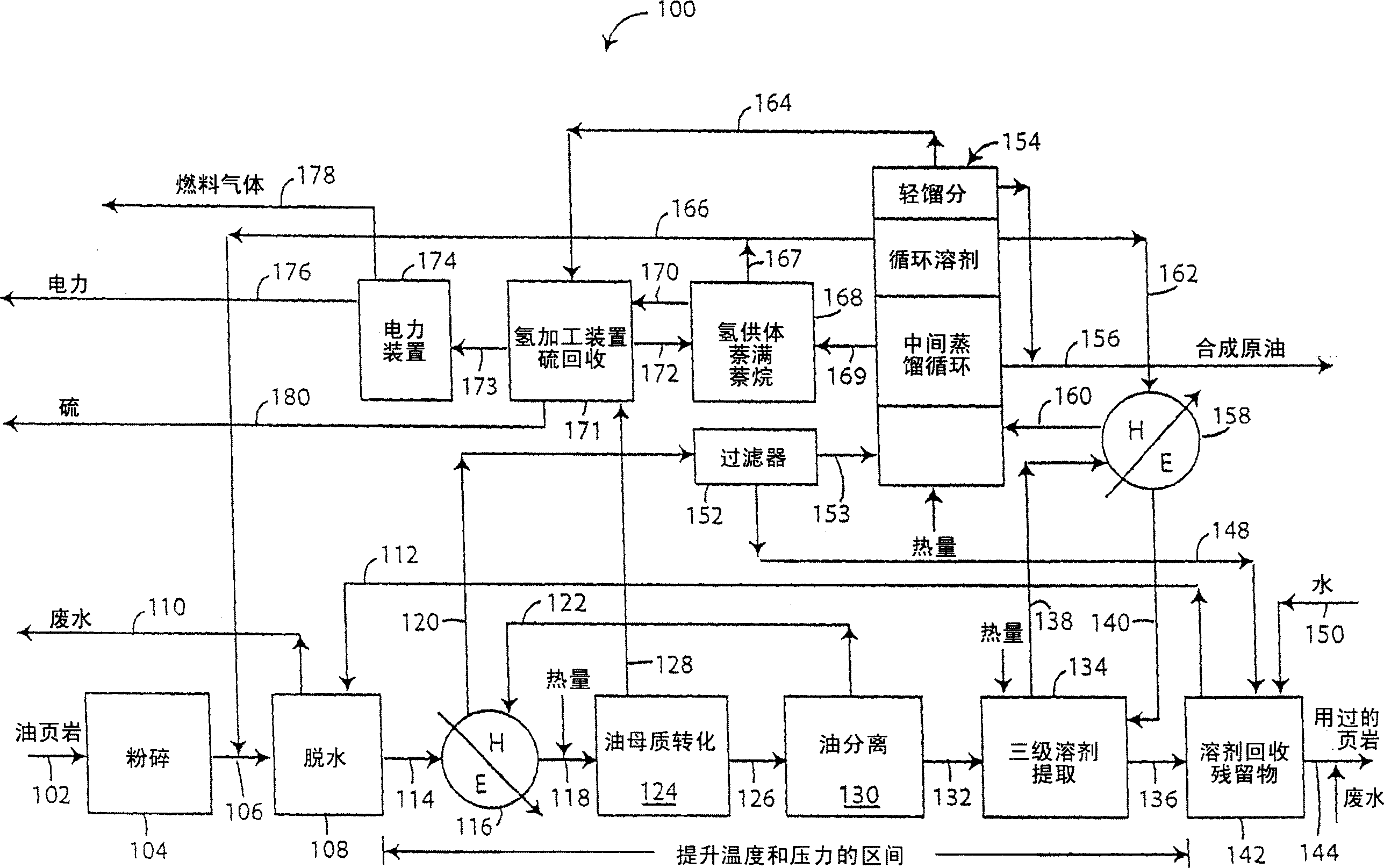

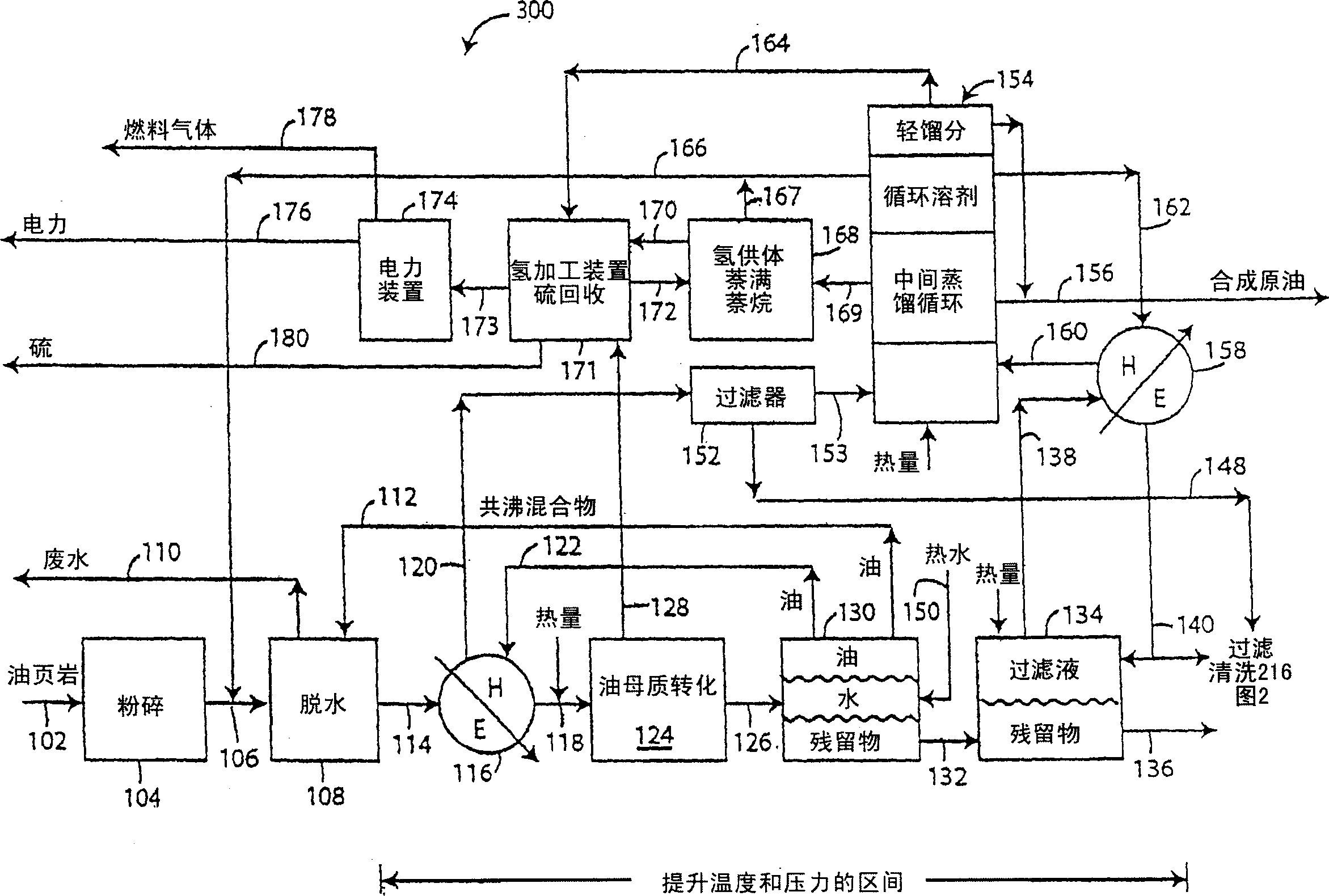

[0037] figure 1 An embodiment of an oil shale processing apparatus of the present invention is shown in FIG. The main product produced is synthetic crude oil suitable for pipeline transportation. The oil shale input 102 is crushed by a pulverizer 104 . Crushed oil shale stream 106 is mixed with recycled solvent and input to dehydrator 108 . Wastewater 110 is removed from the system. A recovered solvent vapor stream 112 is added, concentrated for heat recovery, and output as a slurry stream 114 . Heat exchanger 116 provides a recovered heat stream 118 and outputs an oil product stream 120 . The downstream process receives hot oil product stream 122 and loses the elevated heat to heat recovered stream 118 , leaving cooled oil product 120 . The kerogen converter 124 outputs a slurry 126 . The reactant gas is exhausted in stream 128 . Oil separator 130 outputs an oily solids stream 132 and an oil product stream 122 . Solvent extractor 134 outputs a solids stream 136 , and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com