Composite-type cement concrete curing agent and preparation method thereof

A technology of cement concrete and curing agent, which is applied in the field of composite cement concrete curing agent and its preparation. It can solve problems such as affecting construction, difficult to remove film formation, and small spraying thickness, so as to reduce water evaporation, improve stability, and good compatibility. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] (1)将硫酸铝、硅酸钠和水按比例投入反应瓶中,其中质量百分比为:硫酸铝10%、硅酸钠25%、水65%;然后,在50℃温度下搅拌25min制得硫酸铝改性硅酸钠溶液,待用。

[0026] (2)按照配比(质量百分比)称取各组分,将水性环氧树脂乳液40%,利用搅拌器控制转速,在低转速(200~400rpm)的情况下,缓慢加入硫酸铝改性的硅酸钠溶液52%以及偶联剂1.5%,搅拌40min,形成均匀稳定的改性乳液。

[0027] (3)然后依次加入成膜助剂3%、流平剂1.5%、消泡剂2%,在高转速(600~850rpm)的情况下搅拌5min后静置,即得到高效的复合型水泥混凝土养护剂。

[0028] 本发明上述实施方式依据JC901-2002《水泥混凝土养护剂》进行测试,结果见表1。

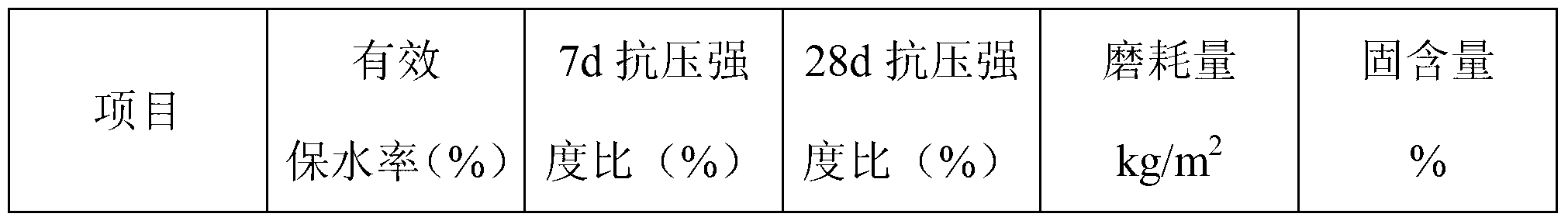

[0029] 表1是本发明上述实施方式进行检测的结果:

[0030]

[0031]

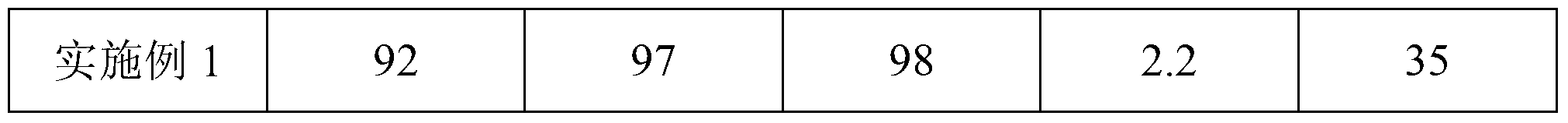

[0032] JC901-2002《水泥混凝土养护剂》对于养护剂性能指标要求如下:

[0033]

[0034] 实施例1制备的养护剂的性能均能满足规范对混凝土养护剂一级品的性能要求,有效保水率达到92%,实现了高效保水目标。

Embodiment 2

[0036] (1)将硫酸铝、硅酸钠和水按比例投入反应瓶中,其中质量百分比为:硫酸铝15%、硅酸钠30%、水55%;然后,在45℃温度下搅拌30min制得硫酸铝改性硅酸钠溶液,待用。

[0037] (2)按照配比(质量百分比)称取各组分,将水性环氧树脂乳液37%,利用搅拌器控制转速,在低转速(200~400rpm)的情况下,缓慢加入54%硫酸铝改性的硅酸钠溶液以及2.5%偶联剂,搅拌35min,形成均匀稳定的乳液。

[0038] (3)然后依次加入成膜助剂4%、流平剂1%、消泡剂1.5%,在高转速(600~850rpm)的情况下搅拌6min后静置,即得到高效的复合型水泥混凝土养护剂。

[0039] 本发明上述实施方式依据JC901-2002《水泥混凝土养护剂》进行测试,结果见表2。

[0040] 表2是本发明上述实施方式进行检测的结果:

[0041]

Embodiment 3

[0043] (1) Put aluminum sulfate, sodium silicate and water into the reaction bottle in proportion, and the mass percentages are: 15% aluminum sulfate, 25% sodium silicate, and 60% water; then, stir at 60°C for 25 minutes to prepare Aluminum sulfate modified sodium silicate solution, ready for use.

[0044] (2) Weigh each component according to the proportion (mass percentage), add 44% of the water-based epoxy resin emulsion, use the stirrer to control the speed, and slowly add aluminum sulfate modified 50% sodium silicate solution and 1.5% coupling agent were stirred for 45 minutes to form a uniform and stable modified emulsion.

[0045] (3) Then add 3% of film-forming aid, 0.5% of leveling agent, and 1% of defoamer in sequence, stir for 4 minutes at high speed (600-850rpm) and then stand still to obtain high-efficiency composite cement concrete curing agent.

[0046] The above embodiments of the present invention were tested according to JC901-2002 "Cement Concrete Curing Age...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com