Synthesis of nano-ZSM-5 molecular sieve

A technology of ZSM-5 and synthesis method, which is applied in the direction of crystalline aluminosilicate zeolite, borocarbane silicone crystalline aluminosilicate zeolite, etc., can solve the problems of increasing the complexity of the post-processing process after increasing the operation repeatability, and achieves the benefit of industrialization Production and application, high specific surface area, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] In the first step, the molar ratio is Al in the aluminum source 2 o 3 : SiO in silicon source 2 : NaOH in alkali source: organic base: H 2 O is 0.025:1:0.12:0.4:12, the aluminum source is sodium metaaluminate, the silicon source is silica sol, the alkali source is sodium hydroxide, and the organic base is isopropylamine .

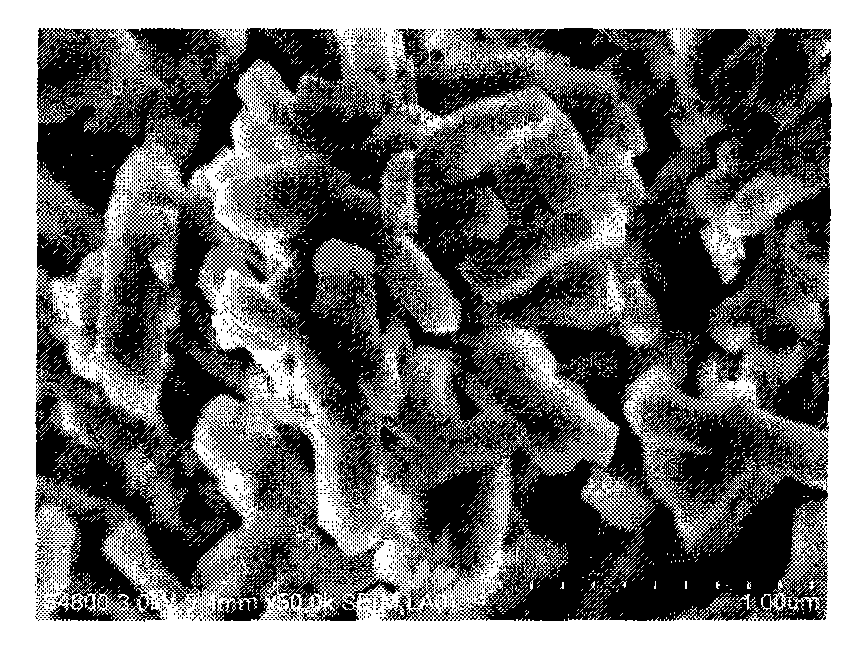

[0021] In the second step, hydrothermal crystallization was carried out at 170° C. for 3 days. The scanning electron micrograph picture of the obtained nanometer ZSM-5 molecular sieve is for reference figure 1 , in the figure: the molecular sieve grain shape is a rod-like structure, the average diameter of the grain section is about 90nm, and the length is about 400nm.

Embodiment 2

[0023] In the first step, the molar ratio is Al in the aluminum source 2 o 3 : SiO in silicon source 2 : NaOH in alkali source: organic base: H 2 O is 0.01:1:0.2:1.0:20, the aluminum source is sodium metaaluminate, the silicon source is silica sol, the alkali source is sodium hydroxide, and the organic base is isopropylamine .

[0024] In the second step, hydrothermal crystallization was carried out at 170° C. for 3 days. The scanning electron micrograph figure of the nano ZSM-5 molecular sieve that obtains and figure 1 Similarly, the average diameter of its grain cross-section is about 85 nm.

Embodiment 3

[0026] In the first step, the molar ratio is Al in the aluminum source 2 o 3 : SiO in silicon source 2 : NaOH in alkali source: organic base: H 2 O is 0.05:1:0.2:1.0:50, the aluminum source is sodium metaaluminate, the silicon source is silica sol, the alkali source is sodium hydroxide, and the organic base is isopropylamine .

[0027] In the second step, hydrothermal crystallization was carried out at 170° C. for 3 days. The scanning electron micrograph figure of the nano ZSM-5 molecular sieve that obtains and figure 1 Similarly, the average diameter of its grain cross-section is about 90 nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com