Strontium calcium aluminium sulphate cement

A technology of calcium strontium sulfoaluminate and sulfoaluminate, which is applied in the field of cement materials, can solve the problems of low strength and achieve the effects of high strength, energy saving and economic benefit improvement in the later stage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

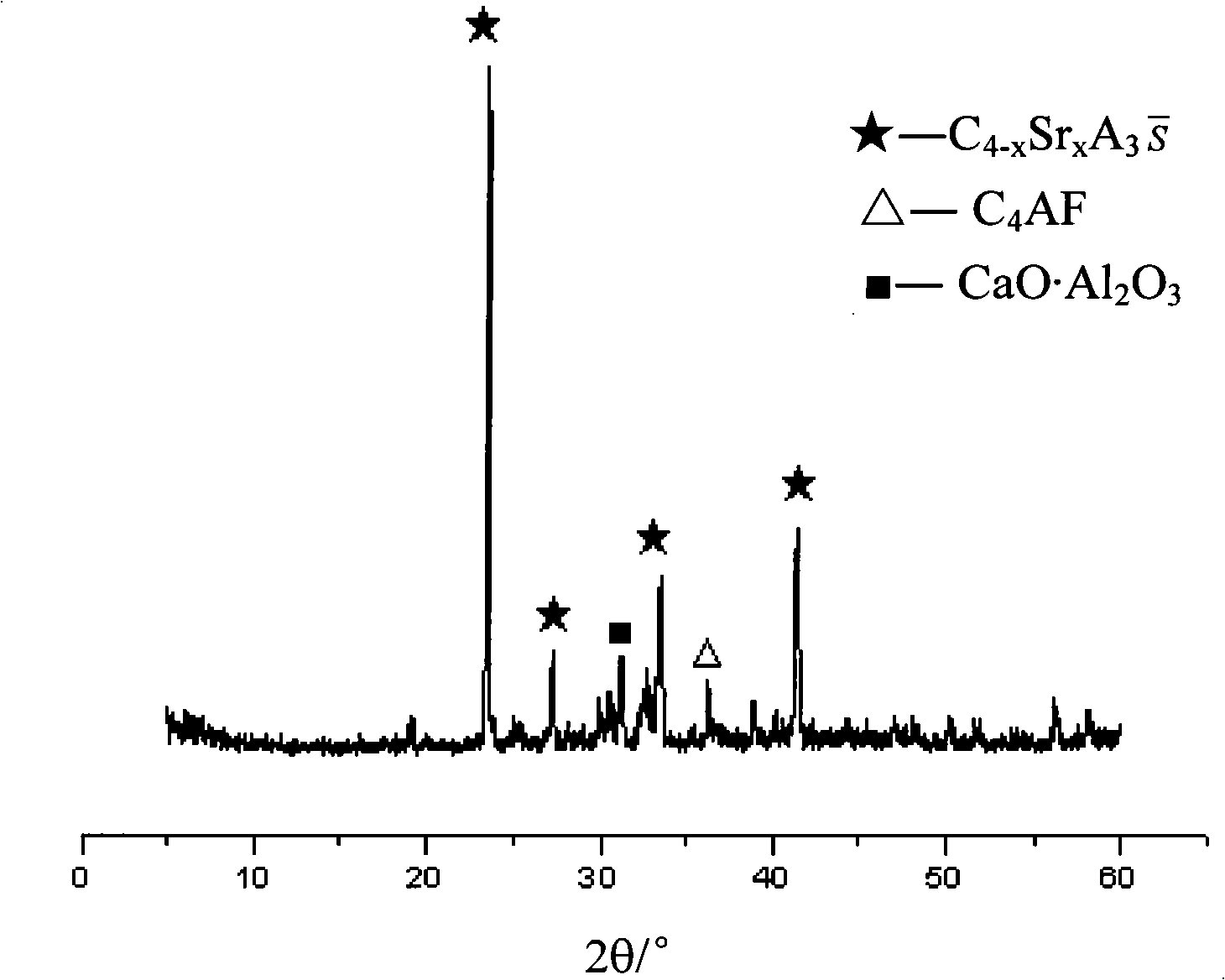

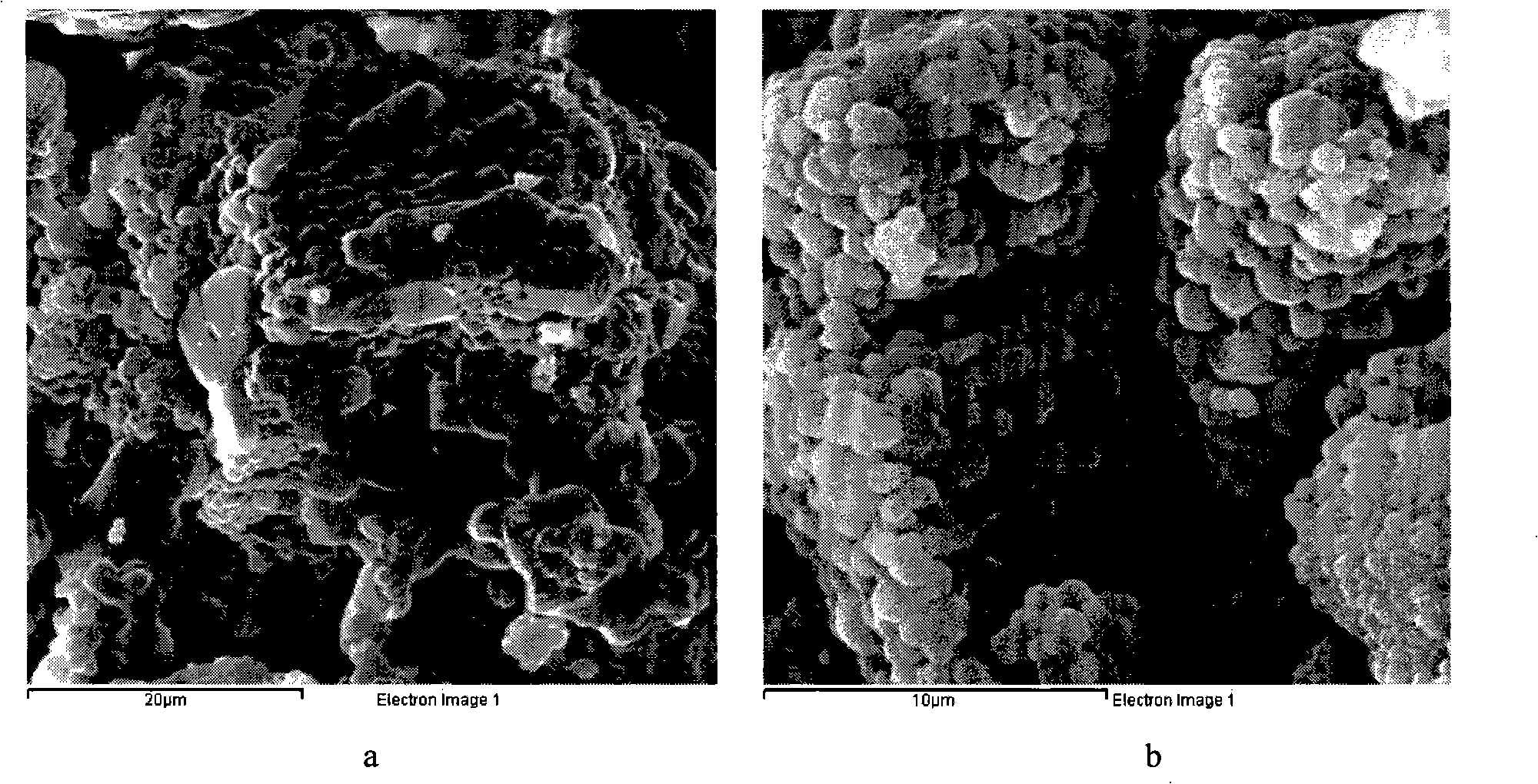

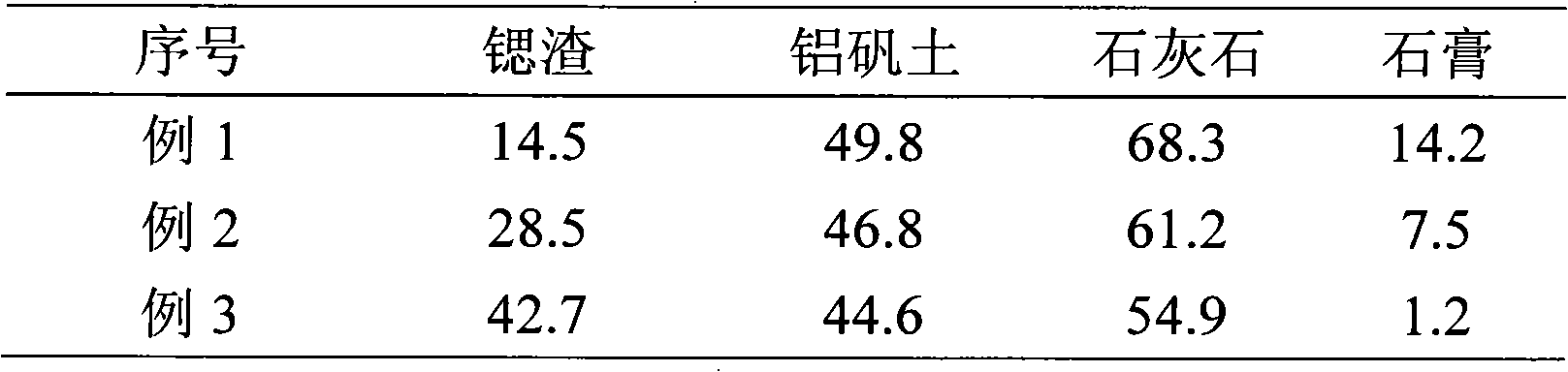

[0028] See Table 1, Table 2, Table 3 and Table 4 for specific examples of strontium calcium sulfoaluminate cement described in the present invention.

[0029] Table 1 raw material formula (kg)

[0030]

[0031] Table 2 Cement clinker mineral composition %

[0032]

[0033] Table 3 Cement clinker chemical composition %

[0034]

[0035] For the above three types of clinker, 5% gypsum was added, and the physical properties of the cement are shown in Table 4.

[0036] Table 4 cement physical properties

[0037]

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com