Foam concrete and preparing process thereof

A foam concrete and foaming agent technology, applied in the field of concrete, can solve the problems affecting the normal use of foam concrete, low tensile strength of foam concrete, large shrinkage of foam concrete, etc., achieve good waterproof effect, low water absorption, and reduce plasticity Effect of Shrinkage Crack and Stress Crack Levels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

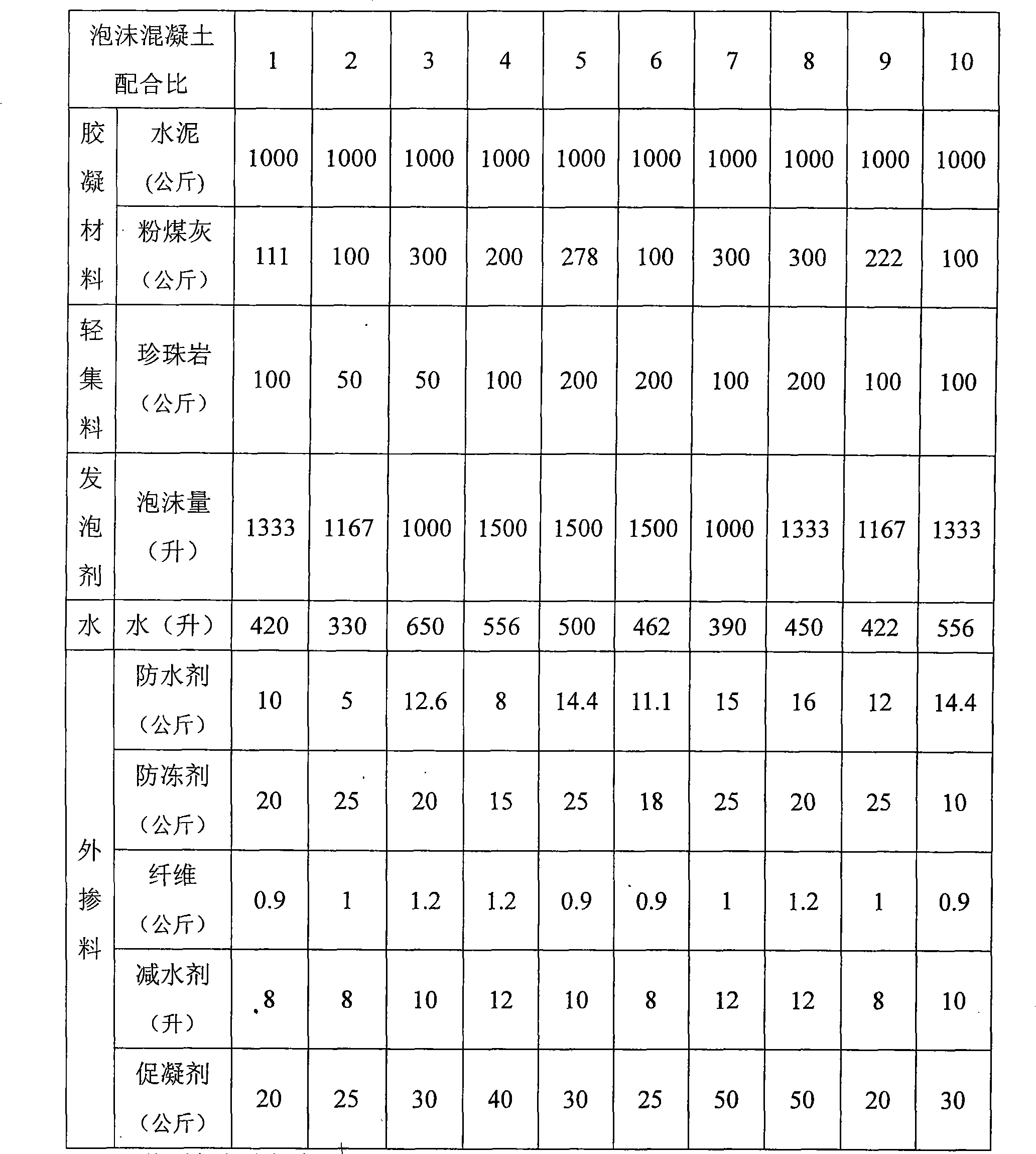

[0076] A kind of foam concrete, it is made up of following weight percent raw material:

[0077] Raw material parts by weight

[0078] (1) Gelling material:

[0079] Cement 100 parts

[0080] Fly ash 25 parts

[0081] (2) Light aggregate:

[0082] 15 parts perlite

[0083] (3) 45 parts of water

[0084] (4) Additives:

[0085] Waterproofing agent 1.5 parts

[0086] Antifreeze 1.8 parts

[0087] 1 part water reducer

[0088] Coagulant 3.5 parts

[0089] Fiber 0.1 parts

[0090] (5) Foaming agent: the percentage of volume (liter) to cement weight (kg) is 100-170%.

[0091] A preparation method of foam concrete, comprising the following steps:

[0092] 1. Selection of raw materials: The cement is 42.5-grade ordinary Portland cement produced by Huaxin Cement Co., Ltd. on the market, and its performance preparation complies with the provisions of GB175-1999 "Portland cement, ordinary Portland cement"; The first-class fly ash produced by Wuhan Luoyang Power Plant is sel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com