Nano foamed concrete, reinforced insulation wallboard and preparation method of reinforced insulation wallboard

A technology of nano-foam and thermal insulation wallboard, applied in the direction of building components, buildings, building structures, etc., can solve the problem of insufficient consideration of volume shrinkage resistance, damping and shock resistance, environmental protection benefits, reduced foam stability, and failure to consider wave absorbing agents. and other problems, to achieve the effect of excellent mechanical properties and thermal insulation properties, reduced density, and uniform pore structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

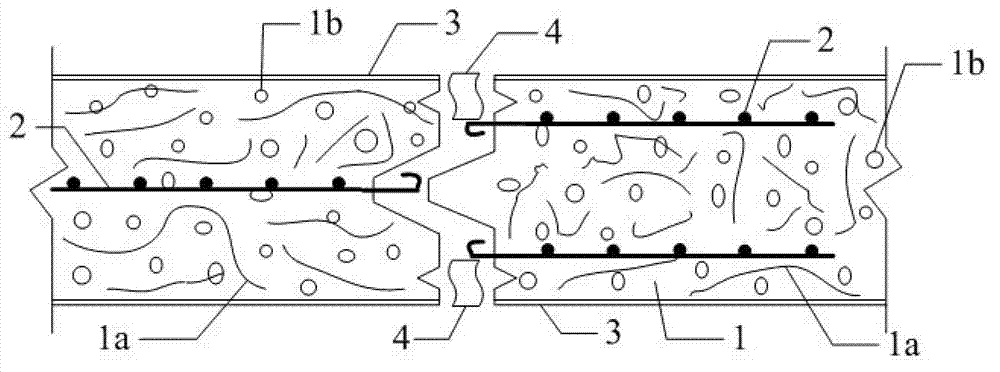

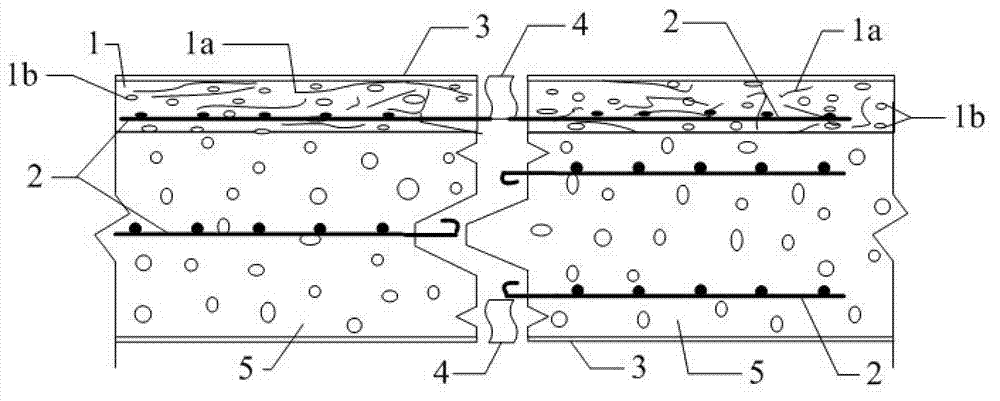

[0040] Such as figure 1 As shown, the nano-foamed concrete and reinforced thermal insulation wallboard products of the present invention include a nano-foamed concrete layer 1, a steel mesh skeleton 2 formed by a double-layer upper and lower layers, and water-resistant face protection paper 3 on the upper and lower surfaces and the embedding filling joints Mortar4. In addition to the hardened concrete, the nano-foam concrete layer also includes fiber nano-wave absorbing agent 1a and micro-bubbles 1b distributed therein.

[0041] The preparation steps of nano foam concrete products are as follows:

[0042] (1) Dissolve 0.5 parts of polycarboxylic acid superplasticizer MPEG in 60 parts of water, add 0.05 parts of carbon nanofibers CNFs with a diameter of 60-100 nm and a length of 6-30 μm, and perform ultrasonic treatment for 1 hour (ultrasonic power 100W, ultrasonic frequency 40kHz, every ultrasonic 50s, pause 10s, a total of 60 times), then add 6 parts of foaming agent SDBS, ...

Embodiment 2

[0048] The steel mesh skeleton in the embedded steel mesh insulation wallboard products is a single-layer steel mesh that has been erected at the half-height of the middle of the wallboard before the nano foam concrete slurry is spread. Others are with embodiment 1.

[0049] Respectively refer to GB / T11969-2008 "Autoclaved Air-entrained Concrete Performance Test Method", GB / T17671-1999 "Cement Mortar Strength Test Method", GB / T10294-2008 "Steady-state Thermal Resistance of Thermal Insulation Materials and Determination and Protection of Related Properties Hot plate method, JC / T603-2004 "Cement mortar dry shrinkage test method" to measure the dry density, volume water absorption, compressive strength and thermal conductivity of the corresponding nano-foam concrete and reinforced thermal insulation wallboard products , the dry shrinkage rate is 351kg / m 3 , 3.5%, 1.70MPa, 0.0589W / m.k. Referring to the damping test method of nanocomposite products in Chinese patent ZL20081006411...

Embodiment 3

[0051] The preparation process and structure of nano-foam concrete and reinforced thermal insulation wallboard products are the same as in Example 1. The difference is: the foaming agent used is modified tea saponin FP-5A, the superplasticizer is aliphatic hydroxysulfonate condensate superplasticizer, and the nano wave absorbing agent is graphene oxide GO with a diameter of 500nm. The waterproofing agent used is calcium stearate, and the cement used is P.O.525R early-strength ordinary Portland cement.

[0052] Respectively refer to GB / T11969-2008 "Autoclaved Air-entrained Concrete Performance Test Method", GB / T17671-1999 "Cement Mortar Strength Test Method", GB / T10294-2008 "Steady-state Thermal Resistance of Thermal Insulation Materials and Determination and Protection of Related Properties Hot plate method, JC / T603-2004 "Cement mortar dry shrinkage test method" to measure the dry density, volume water absorption, compressive strength and thermal conductivity of the correspond...

PUM

| Property | Measurement | Unit |

|---|---|---|

| drying shrinkage | aaaaa | aaaaa |

| drying shrinkage | aaaaa | aaaaa |

| drying shrinkage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com