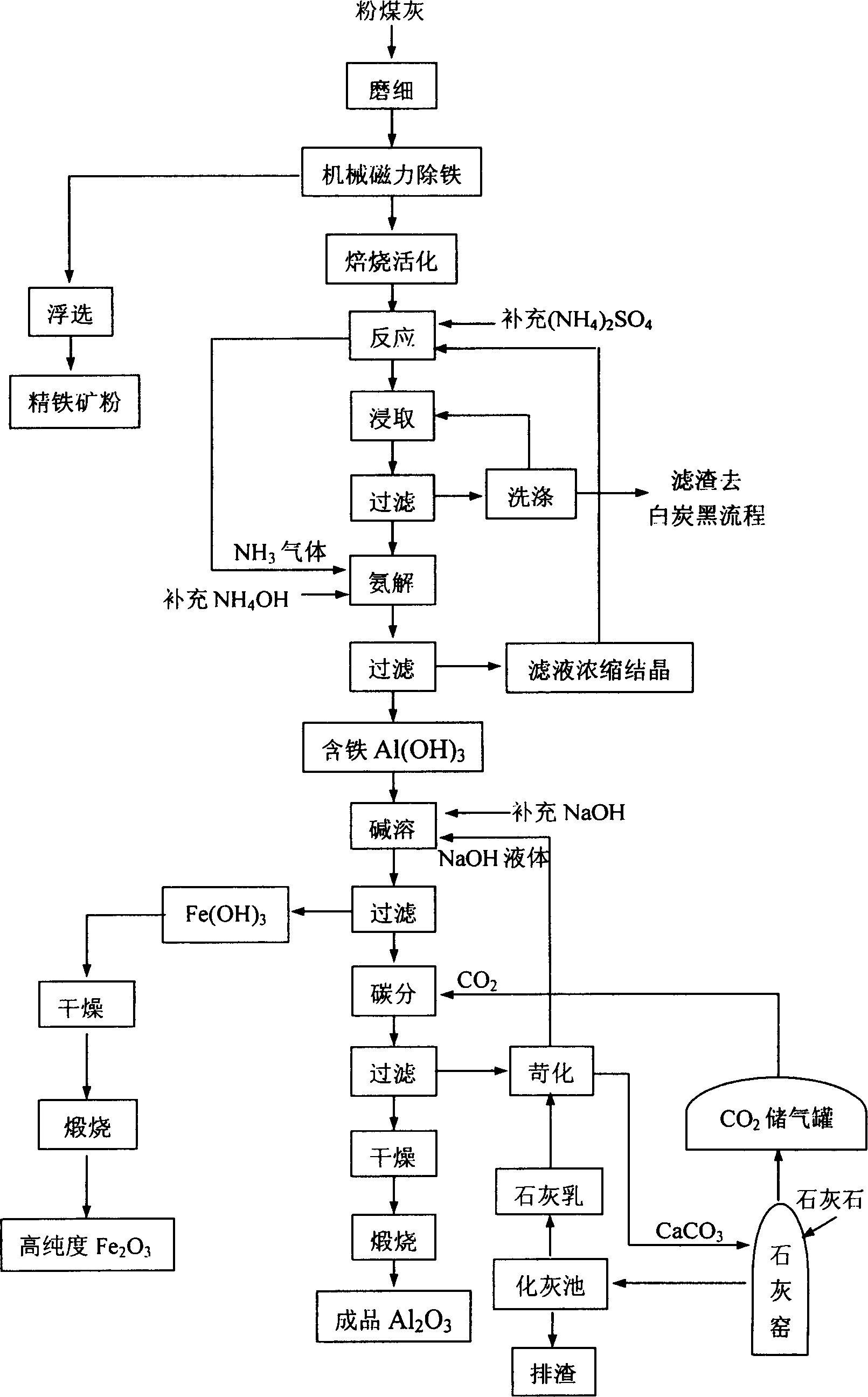

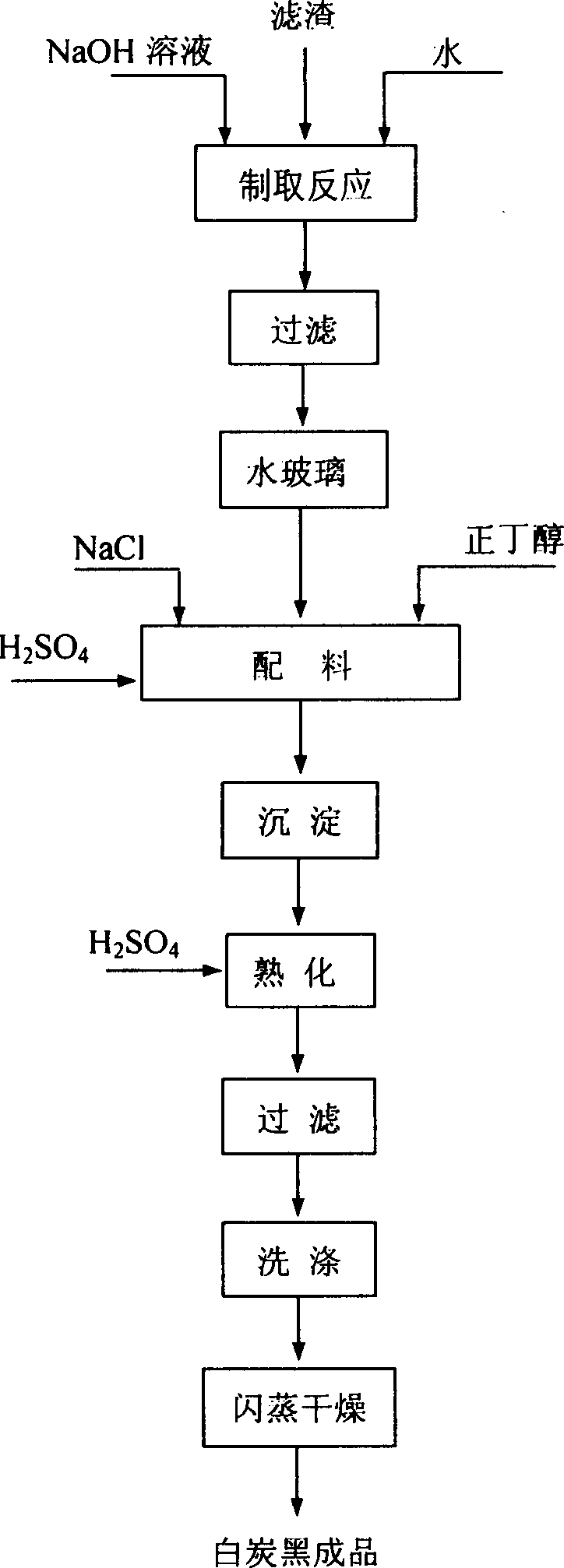

Method of extracting aluminium oxide from fly ash and simultaneously producing white carbon black

A technology of fly ash and alumina, applied in the directions of alumina/aluminum hydroxide, silicon oxide, silicon dioxide, etc., can solve the problems of easily polluted environment, complicated process, many by-products, etc., and achieves high activity and simple process. , the effect of improving the extraction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Embodiment 1: the method for co-producing white carbon black while extracting alumina from fly ash has the following steps:

[0025] 1. Grind the fly ash to 400 mesh, carry out mechanical magnetic iron removal, and then activate it by roasting at 600°C for 1 hour.

[0026] 2. Mix the activated fly ash and ammonium sulfate according to the requirements, according to the weight ratio of alumina and ammonium sulfate in the fly ash is 1:5, stir evenly, enter the reactor, and carry out solid phase reaction at 360°C , and the time is 1 hour.

[0027] 3. Add water to the above reactant, stir and leach for 20 minutes under normal pressure boiling state, and filter.

[0028] 4. Add ammonia gas (ammonia water) in proportion to the filtrate obtained in the previous step, and form a mixed precipitation of aluminum hydroxide and iron hydroxide with the molar ratio of alumina reaction amount in the fly ash to ammonia gas (ammonia water) as 1:7 and ammonium sulfate solution, after s...

Embodiment 2

[0034] Embodiment 2: the method for co-producing white carbon black while extracting alumina from fly ash has the following steps:

[0035] 1. Grind the fly ash to 500 mesh, carry out mechanical and magnetic iron removal, and then activate it by roasting at 700°C for 2 hours.

[0036] 2. Mix the activated fly ash and ammonium sulfate according to the requirements, according to the weight ratio of alumina and ammonium sulfate in the fly ash is 1:6, stir evenly, enter the reactor, and carry out solid phase reaction at 460 °C , and the time is 3 hours.

[0037] 3. Add water to the above reactant, stir and leach for 40 minutes under normal pressure boiling state, and filter.

[0038] 4. Add ammonia gas (ammonia water) in proportion to the filtrate obtained in the previous step, and form a mixed precipitation of aluminum hydroxide and iron hydroxide with the molar ratio of alumina reaction amount in the fly ash to ammonia gas (ammonia water) as 1:8 and ammonium sulfate solution, ...

Embodiment 3

[0043] Embodiment 3: the method for co-producing white carbon black while extracting alumina from fly ash has the following steps:

[0044] 1. Grind the fly ash to 450 mesh, carry out mechanical and magnetic iron removal, and then activate it by roasting at 650°C for 1.5 hours.

[0045] 2. Mix the activated fly ash and ammonium sulfate according to the requirements. According to the weight ratio of alumina and ammonium sulfate in the fly ash is 1:5.5, stir evenly, enter the reactor, and carry out solid-state reaction at 410°C , and the time is 2 hours.

[0046] 3. Add water to the above reactant, stir and leach for 30 minutes under normal pressure boiling state, and filter.

[0047] 4. Add ammonia gas (ammonia water) in proportion to the filtrate obtained in the previous step, and form a mixed precipitation of aluminum hydroxide and ferric hydroxide with the molar ratio of alumina reaction amount in the fly ash to ammonia gas (ammonia water) as 1:7.5 and ammonium sulfate sol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com