Ultraviolet/heating-curing epoxy resin adhesive and preparation method thereof

An epoxy resin, dual-curing technology, applied in the direction of epoxy resin glue, adhesive, adhesive type, etc., can solve the problem of poor compatibility and stability, poor stability of compatibilizer, and poor crosslinking density Insufficient and other problems, to avoid compatibility and stability problems, solve storage stability, and reduce storage costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

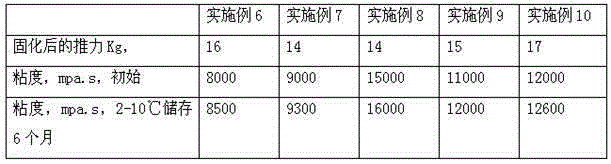

Examples

Embodiment 1

[0046] Example 1, an epoxy resin adhesive that can be double-cured by ultraviolet heating, which is made of the following mass percentage of raw materials:

[0047] Bisphenol A epoxy resin 20%, alicyclic epoxy resin 50%,

[0048] Aromatic sulfonium salt 2%, hexafluoroantimonate 1%,

[0049] Aliphatic glycidyl ether 12%, polyester diol 10%,

[0050] Fumed silica 4%, carbon black 1%.

Embodiment 2

[0051] Embodiment 2, an epoxy resin adhesive that can be double-cured by ultraviolet heating, which is made of the following mass percentage of raw materials:

[0052] Bisphenol A type epoxy resin 10%, bisphenol F type epoxy resin 15%, alicyclic epoxy resin 45%,

[0053] Aromatic iodonium salt 2%, hexafluoroantimonate 2%,

[0054] Aliphatic diglycidyl ether 10%, cross-linked acrylate polymer 13%,

[0055] Organic bentonite 3%, Sudan black 1%.

Embodiment 3

[0056] Example 3, an epoxy resin adhesive that can be double-cured by ultraviolet heating, which is made of the following mass percentage of raw materials:

[0057] Bisphenol A type epoxy resin 30%, alicyclic epoxy resin 35%,

[0058] Aromatic sulfonium salt 1%, aromatic iodonium salt 2%,

[0059] Hexafluoroantimonate 2%, fumed silica 5%,

[0060] Aliphatic glycidyl ether 8%, aliphatic diglycidyl ether 5%,

[0061] Polyester diol 6%, cross-linked acrylate polymer 5%,

[0062] Carbon black 0.5%, Sudan black 0.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com