Construction method for installing plastic sounding pipe

A construction method and acoustic tube technology, which is applied in basic structure engineering, construction, and basic structure tests, etc., can solve the problems of high construction intensity of workers, inability to achieve acoustic measurement results, and high cost, so as to improve market competitiveness and effectively Good for sound wave transmission and simple construction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

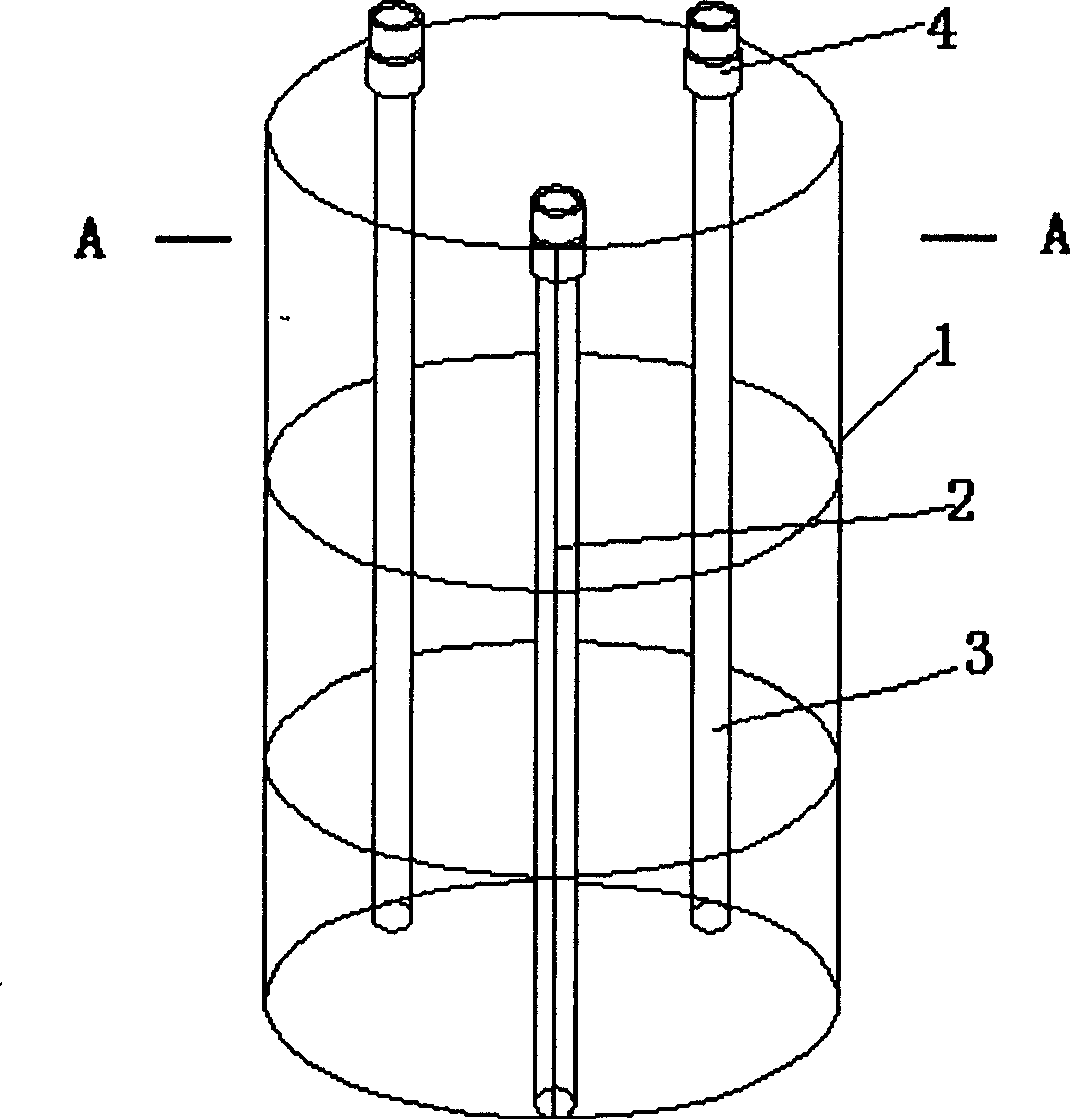

[0023] Further illustrate the specific embodiment of the present invention below in conjunction with accompanying drawing

[0024] Considering that conventional plastic pipes are used as acoustic measuring pipes under the condition of no pressure, and ensure that they are not damaged at a depth of about 50 meters underwater, they must have sufficient strength and toughness to meet the requirements. In the specific embodiment of the present invention, a special UPVC reinforced pipe with an inner diameter of 50 mm, a standard pipe length of 9 meters and a pipe wall thickness of 3 mm is used as the acoustic measuring pipe. Certainly the plastic pipe of the present invention is not limited to UPVC plastic pipe.

[0025] The installation and construction method of the plastic acoustic measuring tube of the present invention comprises the following steps:

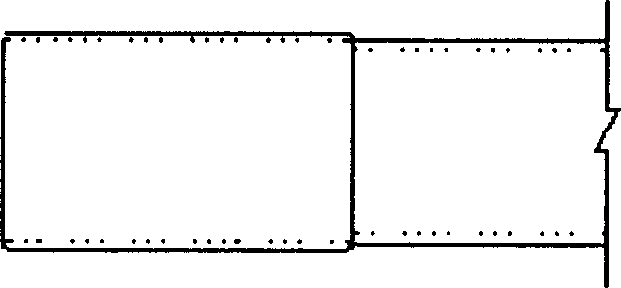

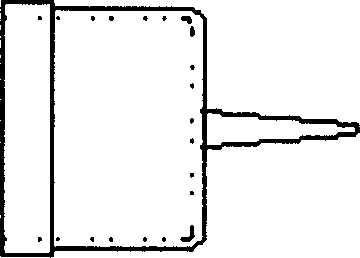

[0026] (1) see figure 1 , Figure 4 , the plastic acoustic tube 3 with the same length as the steel cage 1 is fixedly connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com