Preparation method for carbon fibre fabric-reinforced polyetheretherketone polymer composite material

A technology of carbon fiber fabric and polyether ether ketone, which is applied in the field of preparation of carbon fiber fabric reinforced polyether ether ketone composite materials, can solve the problems of difficult technical and process control, high melt viscosity, high equipment requirements, etc., and achieve good mechanical properties, The effect of simple equipment and simple process method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

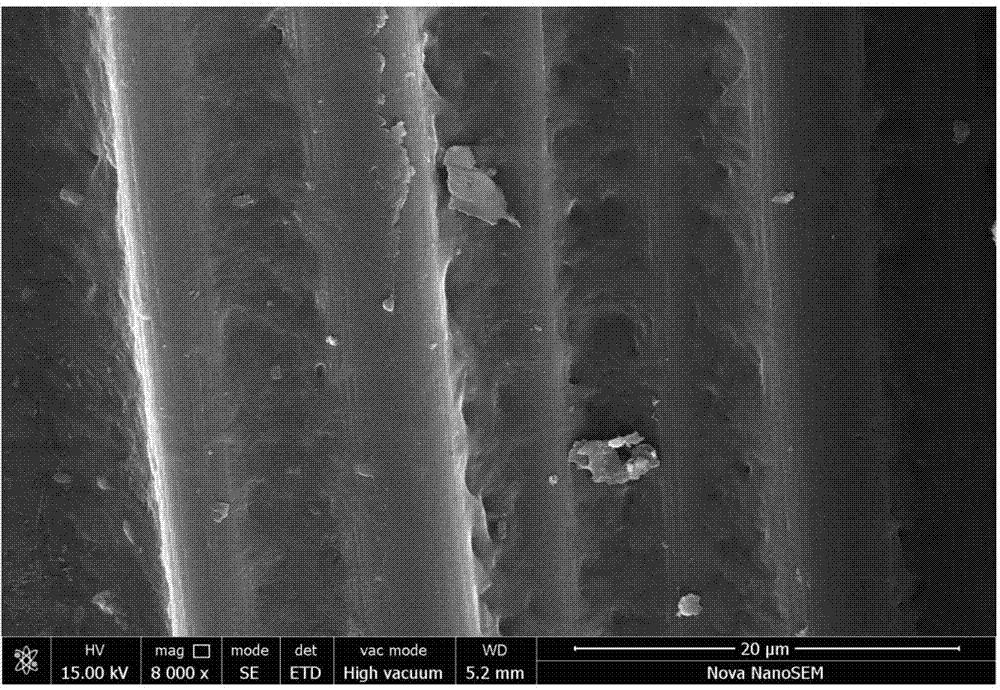

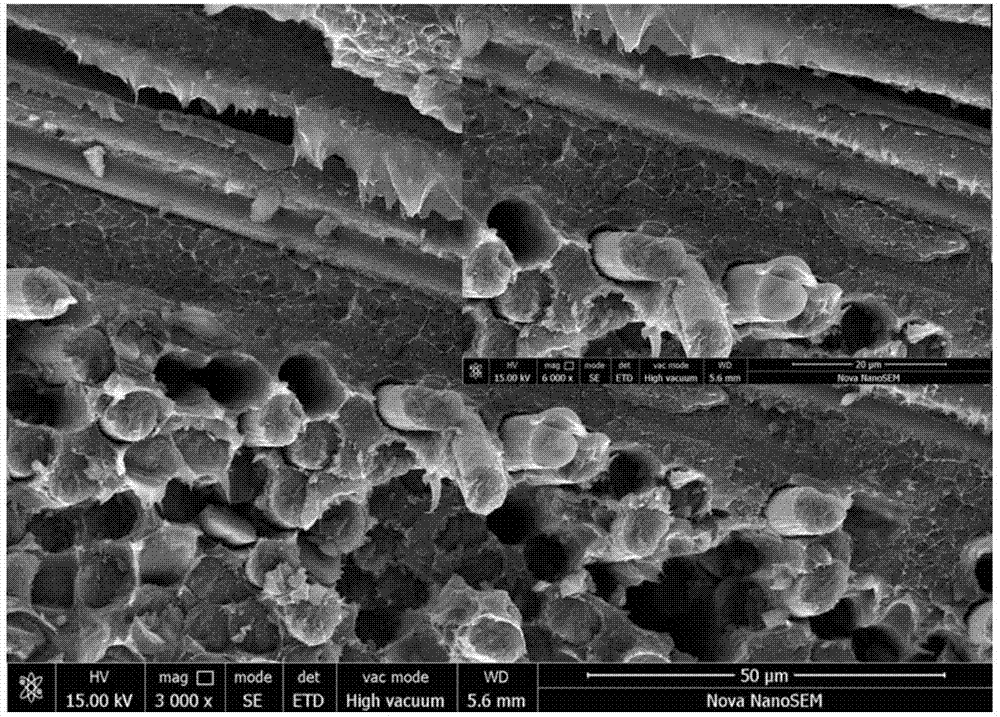

[0023] The plain weave 2D carbon fiber woven preform with a weaving angle θ = 90° is soaked in acetone and heated for 48 to 72 hours with ultrasound to remove the carbon fiber surface sizing agent, then washed with dedistilled water, dried, and weighed. Dissolve the biphenyl polyether ether sulfone (PPSU) powder in an appropriate amount of chloroform to form a polymer solution with a mass concentration of 3.2%, and then in the solution according to the mass ratio of carbon fiber (CF): polyether ether ketone ultrafine powder (PEEK) = 0.45:0.55 ratio of high melt index polyetheretherketone (PEEK) superfine powder is added, fully stirred, so that it is evenly mixed to obtain a suspension. Spread the treated carbon fiber fabric in a cloth funnel, pour the prepared suspension on the carbon fiber fabric, filter under low pressure, and take it out after the chloroform is completely volatilized. Put it in a hot press, raise the temperature to 380°C, melt for 60 minutes, pressurize at ...

Embodiment 2

[0025] Soak the twill 2D carbon fiber woven preform with a weaving angle θ = 90° in acetone and heat it ultrasonically for 48-72 hours to remove the carbon fiber surface sizing agent, then wash it with dedistilled water, dry it, and weigh it. Dissolve the biphenyl polyether ether sulfone (PPSU) powder in an appropriate amount of chloroform to form a polymer solution with a mass concentration of 3.2%, and then in the solution according to the mass ratio of carbon fiber (CF): polyether ether ketone ultrafine powder (PEEK) = 0.45:0.55 ratio of high melt index polyetheretherketone (PEEK) superfine powder is added, fully stirred, so that it is evenly mixed to obtain a suspension. Spread the treated carbon fiber fabric in a cloth funnel, pour the prepared suspension on the carbon fiber fabric, filter under low pressure, and take it out after the chloroform is completely volatilized. Put it in a hot press, raise the temperature to 380°C, melt for 60 minutes, pressurize at 15MPa, and ...

Embodiment 3

[0027] The plain weave 2D carbon fiber woven preform with a weaving angle θ = 90° is soaked in acetone and heated for 48 to 72 hours with ultrasound to remove the carbon fiber surface sizing agent, then washed with dedistilled water, dried, and weighed. Dissolve polyethersulfone (PES) powder in an appropriate amount of DMF to form a polymer solution with a mass concentration of 3.2%, and then in the solution by mass ratio carbon fiber (CF): polyetheretherketone ultrafine powder (PEEK) = 0.45: Add high melt index polyetheretherketone (PEEK) superfine powder at a ratio of 0.55, and stir well to make it evenly mixed to obtain a suspension. Spread the treated carbon fiber fabric on the cloth funnel, pour the prepared suspension on the carbon fiber fabric, filter it with low pressure, dry it and take it out. Put it in a hot press, raise the temperature to 380°C, melt for 60 minutes, pressurize at 15MPa, and keep the pressure for 30 minutes. Then cool at a moderate cooling rate of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com