Cation-doped gradient high-nickel multi-material precursor and preparation method and application thereof

A technology of doping gradients and cations, applied in electrical components, battery electrodes, circuits, etc., can solve problems such as hindering the industrialization process, poor rate performance and cycle performance of multi-component materials, and complex synthesis process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

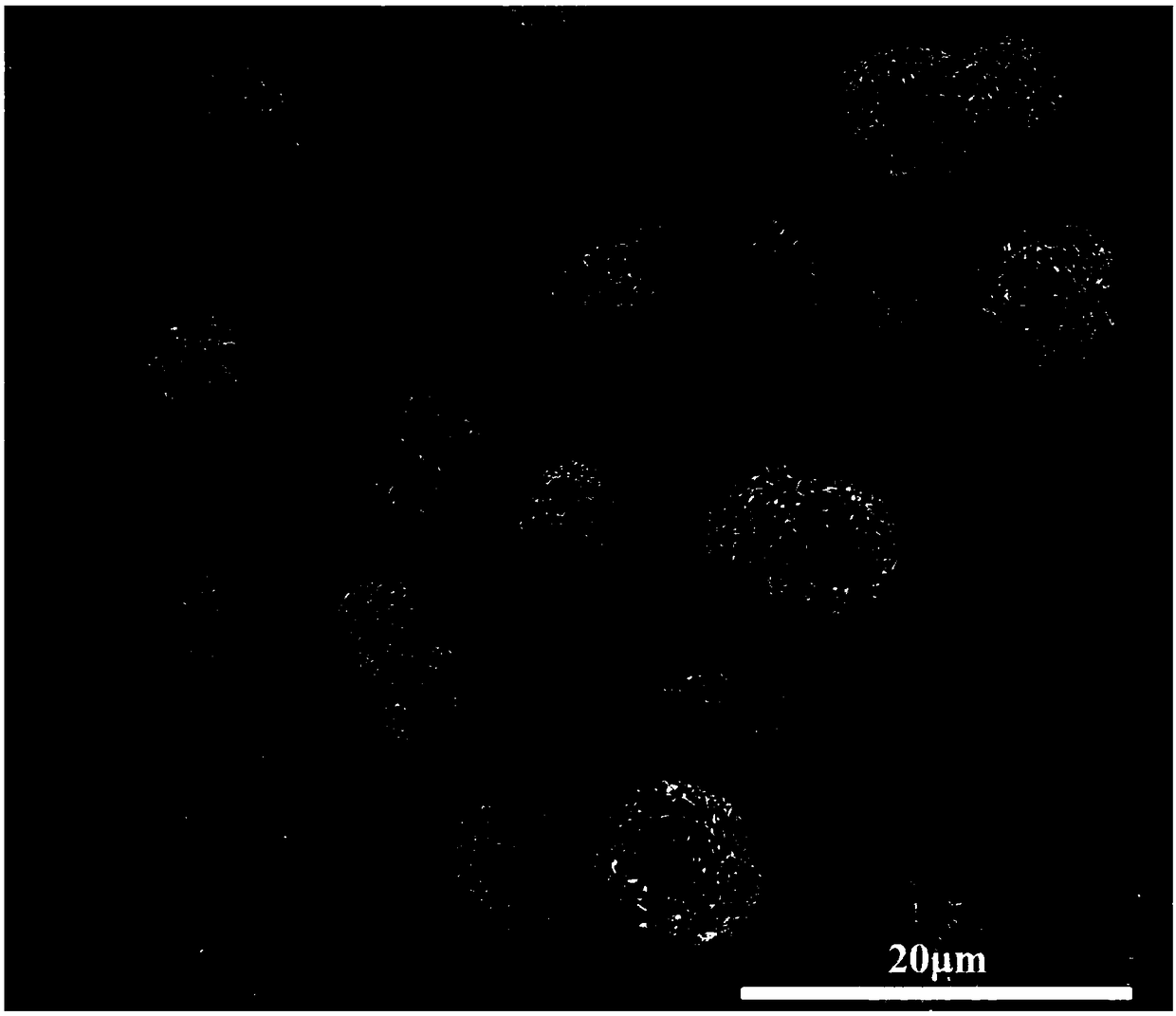

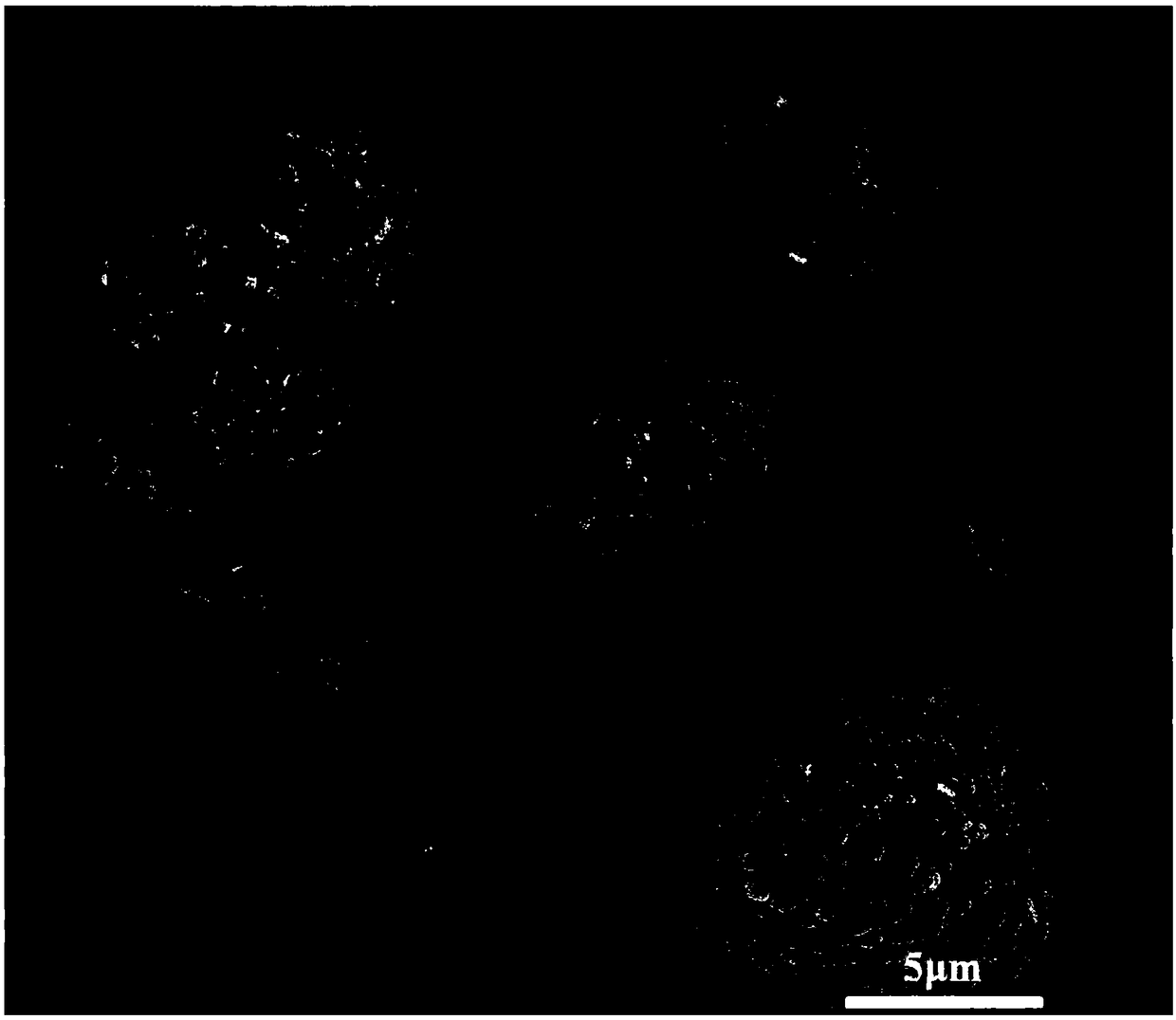

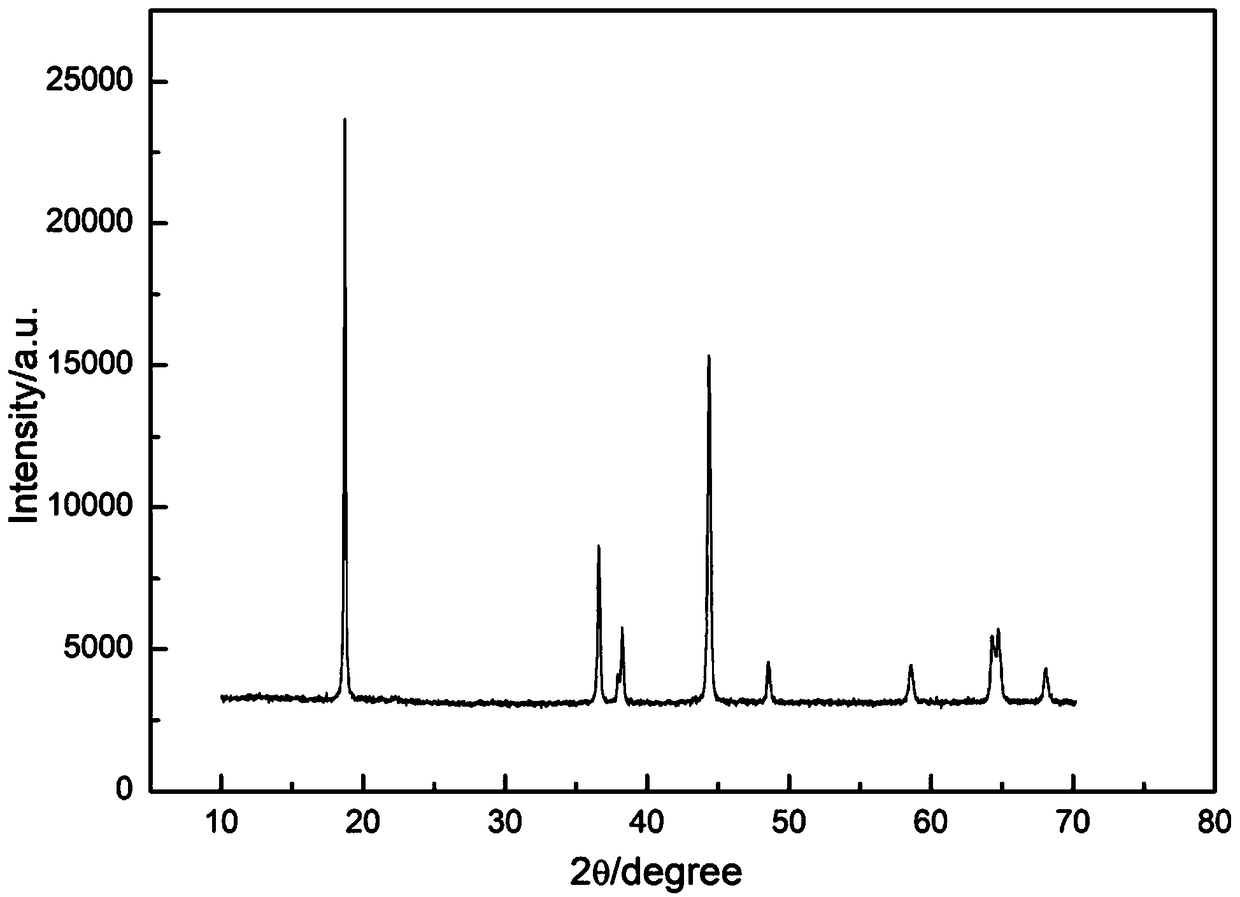

[0040] This embodiment prepares Al 3+ Gradient high-nickel ternary precursor Ni modified by doping 0.7992 co 0.0999 mn 0.0999 Al 0.001 (OH) 2.001 and gradient high-nickel multi-element material LiNi 0.7992 co 0.0999 mn 0.0999 Al 0.001 o 2 , including the following steps:

[0041] (1) Preparation of nickel salt and doped metal salt solutions: Weigh 7.992 mol of nickel sulfate hexahydrate and 0.005 mol of aluminum sulfate octadecahydrate respectively, dissolve them in an appropriate amount of pure water, and prepare 8.002 liters of salt solution A.

[0042] (2) cobalt salt and manganese salt solution preparation: with nickel salt, cobalt salt and manganese salt according to mol ratio Co:Mn=8:1:1, according to the result of step (1), take by weighing 0.999mol cobalt sulfate heptahydrate and 0.999 mol of manganese sulfate monohydrate was dissolved in an appropriate amount of pure water to prepare 1.998 liters of salt solution B.

[0043] (3) Precipitating agent preparat...

Embodiment 2

[0054] This embodiment prepares Zr 4+ Gradient high-nickel ternary precursor Ni modified by doping 0.7976 co 0.0997 mn 0.0997 Zr 0.003 (OH) 2.006 and gradient high-nickel multi-element material LiNi 0.7976 co 0.0997 mn 0.0997 Zr 0.003 o 2 , including the following steps:

[0055] (1) Preparation of nickel salt and doped metal salt solutions: Weigh 7.976 mol of nickel sulfate hexahydrate and 0.03 mol of zirconium sulfate tetrahydrate respectively, dissolve them in an appropriate amount of pure water, and prepare 8.006 liters of salt solution A.

[0056] (2) cobalt salt and manganese salt solution preparation: with nickel salt, cobalt salt and manganese salt according to molar ratio Co:Mn=8:1:1, according to the result of step (1), take by weighing 0.997mol cobalt sulfate heptahydrate and 0.997mol of manganese sulfate monohydrate was dissolved in an appropriate amount of pure water to prepare 1.994 liters of salt solution B.

[0057] (3) Precipitating agent preparatio...

Embodiment 3

[0062] This embodiment prepares Zr 4+ with Al 3+ Gradient high-nickel multi-component precursor Ni modified by co-doping 0.7968 co 0.0996 mn 0.099 6 Zr 0.003 Al 0.001 (OH) 2.007 and gradient high-nickel multi-element material LiNi 0.7968 co 0.0996 mn 0.0996 Zr 0.003 Al 0.001 o 2 , including the following steps:

[0063] (1) Preparation of nickel salt and doped metal salt solution: Weigh 7.968mol nickel sulfate hexahydrate, 0.03mol zirconium sulfate tetrahydrate, and 0.005mol aluminum sulfate octadecahydrate respectively, dissolve them in an appropriate amount of pure water, and prepare 8 liters of salt solution A.

[0064] (2) cobalt salt and manganese salt solution preparation: with nickel salt, cobalt salt and manganese salt according to molar ratio Co:Mn=8:1:1, according to the result of step (1), take by weighing 0.996mol cobalt sulfate heptahydrate and 0.996mol of manganese sulfate monohydrate was dissolved in an appropriate amount of pure water to prepare ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com