Preparation method of full-gradient high-nickel ternary precursor and full-gradient high-nickel ternary cathode material

A positive electrode material and full-gradient technology, applied in electrical components, battery electrodes, structural parts, etc., can solve the problems that full-gradient materials are difficult to implement in industrial production, and achieve the effects of easy control, optimized performance, and reduced phase boundary resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

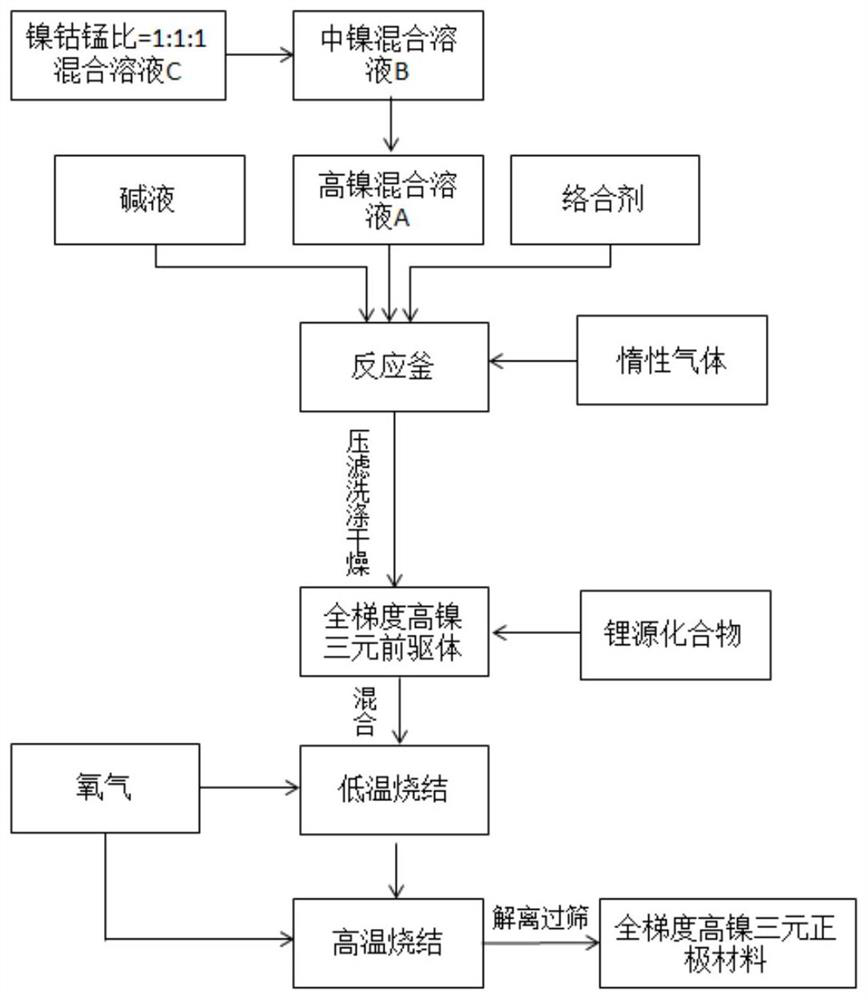

[0039] see figure 1 , the process schematic diagram of the preparation method of the full-gradient high-nickel ternary positive electrode material, adding nickel sulfate and cobalt sulfate in deionized water to prepare 400L mixed solution A, and controlling the molar concentration of nickel and cobalt in the mixed solution A. The ratio is 0.95:0.05, and the sum of the molar concentration of nickel and cobalt in the control mixed solution A is 3mol / L; the mixed solution A is stored in the first raw material tank, and the stirring device arranged in the first raw material tank is started; Add nickel sulfate, cobalt sulfate, and manganese sulfate to deionized water to prepare a 200L mixed solution B, and control the molar concentration of nickel, cobalt, and manganese in the mixed solution B to a ratio of 5:2:3. The sum of the molar concentration of nickel, the molar concentration of cobalt and the molar concentration of manganese in mixed solution B is 2mol / L; Mixed solution B i...

Embodiment 2

[0044] see figure 1 , the schematic diagram of the process flow of the preparation method of the full-gradient high-nickel ternary positive electrode material, adding nickel sulfate, cobalt sulfate, and manganese sulfate in deionized water to prepare 300L mixed solution A, and controlling the molar concentration of nickel and cobalt in the mixed solution A The ratio of the molar concentration to the molar concentration of manganese is 8:1:1, and the sum of the molar concentration of nickel and cobalt in the mixed solution A is controlled to be 2mol / L; the mixed solution A is stored in the first raw material tank and started Stirring device provided in the first raw material tank; add nickel sulfate, cobalt sulfate, manganese sulfate in deionized water to prepare 100L mixed solution B, control the molar concentration of nickel, cobalt and manganese in the mixed solution B The ratio is 6:2:2, and the sum of the molar concentration of nickel, cobalt and manganese in the mixed sol...

Embodiment 3

[0046] see figure 1, the schematic diagram of the process flow of the preparation method of the full-gradient high-nickel ternary positive electrode material, nickel sulfate is added to deionized water to prepare 300L mixed solution A, and the molar concentration of nickel in the mixed solution A is controlled to be 4mol / L; the mixed solution A Store in the first raw material tank, start the stirring device that is provided with in the first raw material tank; Add nickel sulfate, cobalt sulfate, manganese sulfate in deionized water, prepare the mixed solution B of 100L, control the molar concentration of nickel in the mixed solution B, The ratio of the molar concentration of cobalt to the molar concentration of manganese is 4:2:4, and the sum of the molar concentration of nickel, the molar concentration of cobalt and the molar concentration of manganese in the mixed solution B is controlled to be 2mol / L; the mixed solution B is stored in In the second raw material tank, start ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com