Powder-material-oriented SLM/SLS powder laying technology

A powder material and powder spreading technology, applied in the field of SLM/SLS powder spreading process, can solve the problems of difficult to meet the gradient material manufacturing, difficult to meet the personalized gradient material manufacturing, hinder the development of 3D printing, etc., and achieve the effect of improving work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

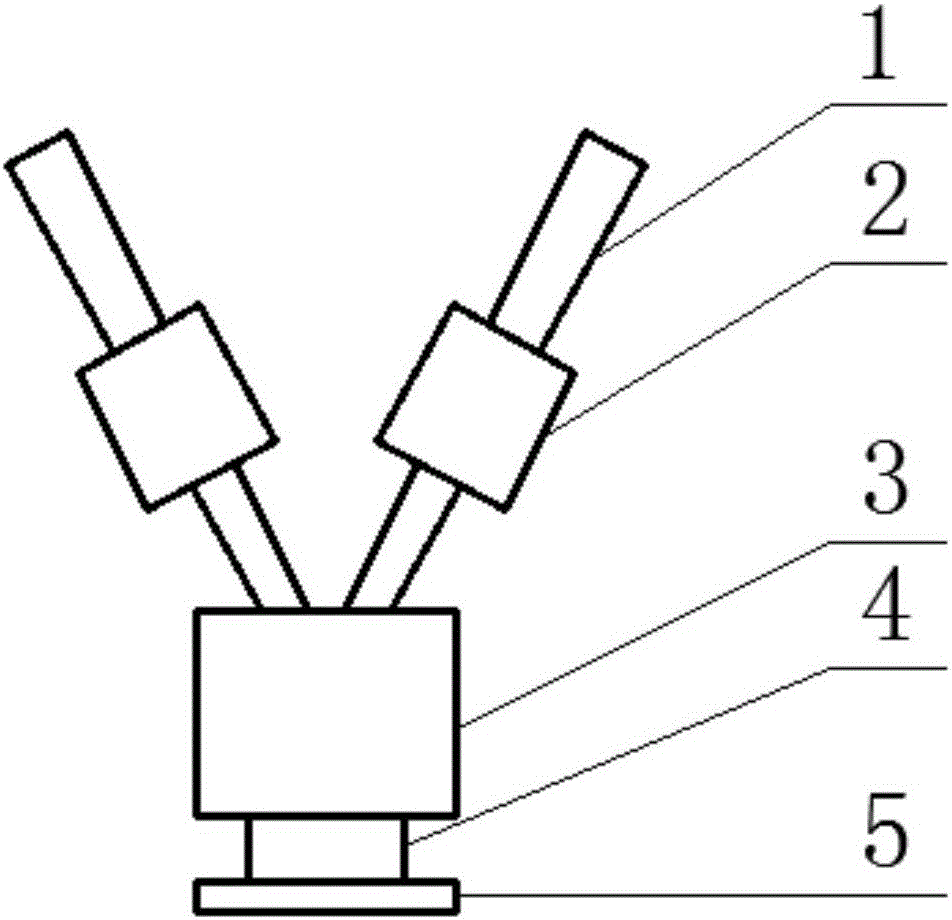

[0022] figure 1 It is the basic structure diagram of the powder mixer. The powder channel inlets 1 are symmetrically distributed, and the number is two or more, which can satisfy the manufacture of two or more materials. The angle between the flow channel direction and the vertical direction is 30 degrees.

[0023] The flow controller 2 is located in the middle of the flow channel, and controls the powder flow through the size of the opening. Each flow channel is equipped with a flow controller, and each flow controller cooperates with each other to obtain mixed powder with different proportions.

[0024] The mixer 3 is connected with the powder flow channel, and different kinds of powders are uniformly mixed in the mixer. There is a stirring device in the mixer, which can fully and evenly mix the powder.

[0025] Below the mixer is the outlet (nozzle) 4 of the powder channel, and the evenly mixed powder flows out onto the workbench from the outlet of the channel.

[0026...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com