3D printing dispensing extruding device capable of realizing online alloying

A technology of 3D printing and extrusion device, applied in the field of 3D printing, can solve the problems of high cost, inability to realize the integrated forming of online batching and metal parts, and low efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

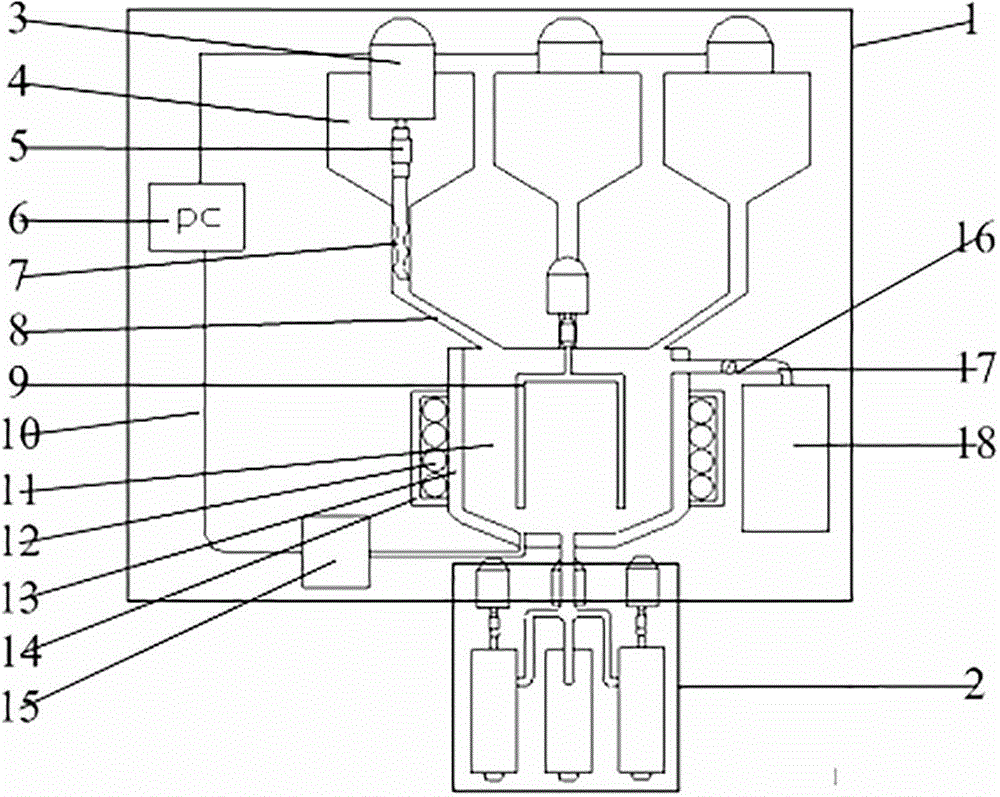

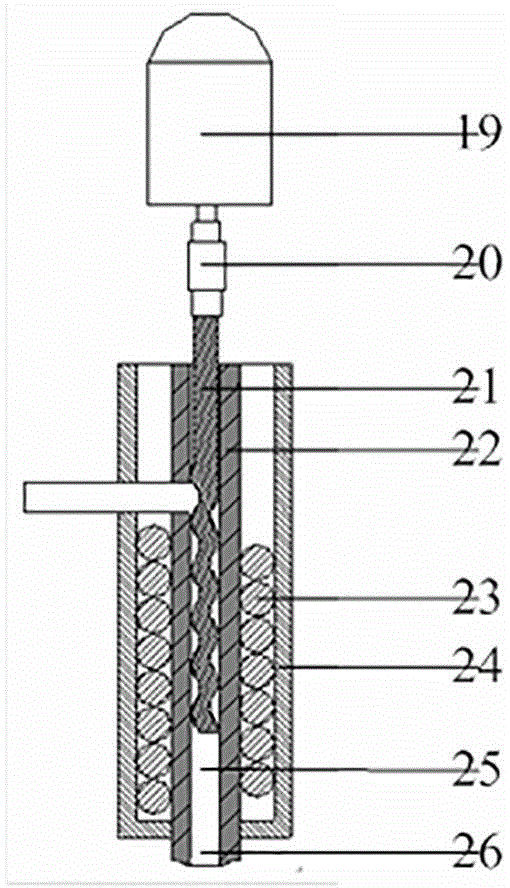

[0017] like figure 1 A new nozzle that can realize online alloying is shown, including an online batching mechanism (1) and a molten metal extrusion nozzle (2), and the online batching mechanism (1) includes no less than one storage bin ( 4), the feeding screw device (7) controlled by the PC (6), the mixing chamber (11) that can realize metal melting, the segmental heating device (12), and the molten metal composition can be realized and fed back to the PC (6) ), the online detection device (15) for the molten metal composition in ), the delivery pipe (8) connecting the mixing chamber (11) and the molten metal extrusion nozzle (2); the molten metal extrusion nozzle (2) includes a nozzle inner chamber (25), the screw (21) and the motor (19) connected by the coupling (20), the section heating device (23) is installed on the outer wall of the nozzle (22), and the thermal insulation layer (24) is installed outside the nozzle heating device ), the mixing chamber (11) and the inner...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com