Precise laser micro-forming and powder feed method and coaxial laser powder device thereof

A powder feeding device and micro-forming technology, applied in metal material coating process, coating and other directions, can solve the requirements of precision micro-forming that are not suitable for micro-nano powder, powder feeding controllability, poor continuity, forming accuracy and quality It can achieve the effect of low cost, good optical powder coupling performance and high forming accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

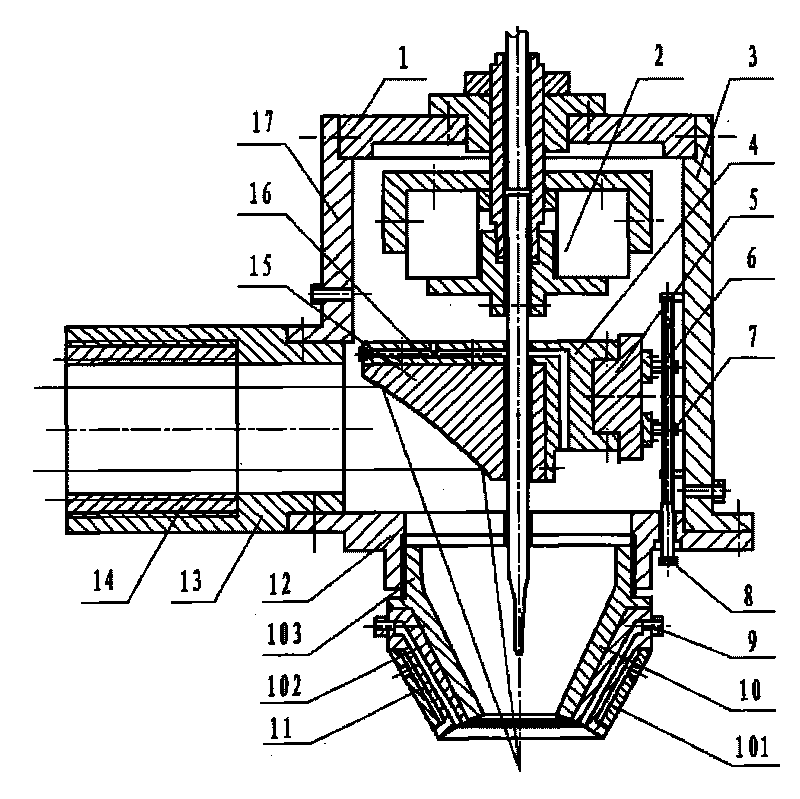

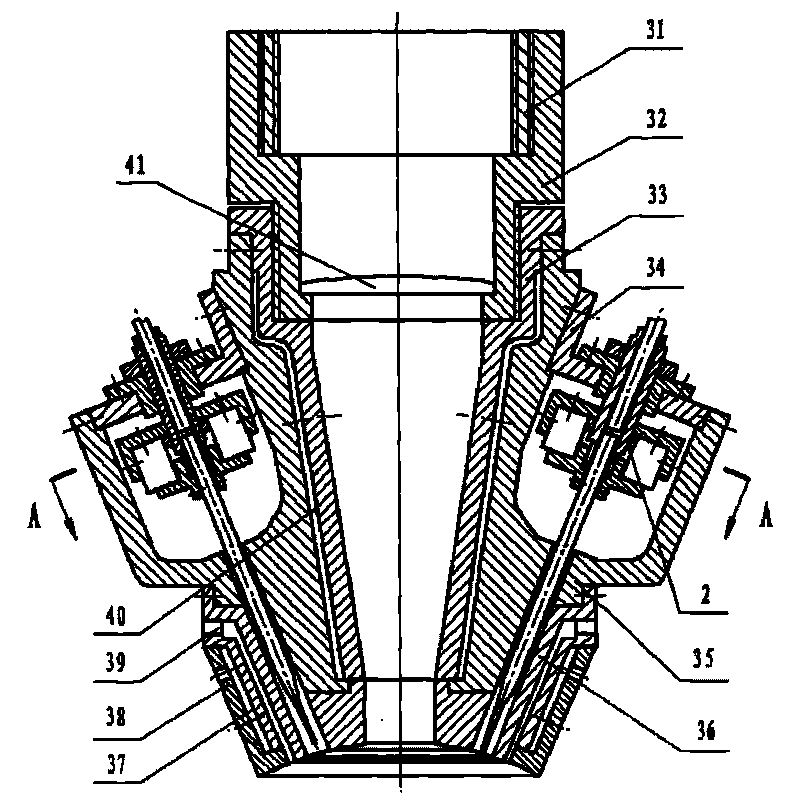

[0026] The present invention will be further described below in conjunction with the accompanying drawings.

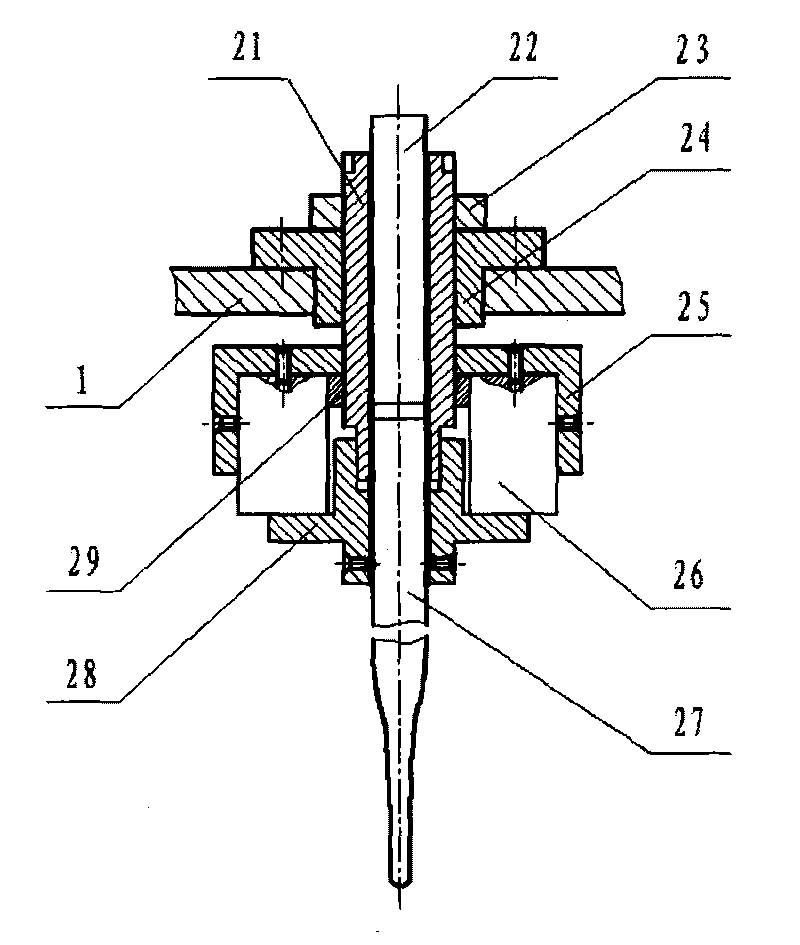

[0027] Such as figure 2 As shown, a laser precision micro-forming powder feeding method of the present invention uses a powder feeding device 2 for piezoelectric-driven powder feeding. After the piezoelectric ceramic of the piezoelectric driver 26 in the powder feeding device 2 is powered on, its inverse piezoelectric effect The generated pulse inertial force is transmitted to the quartz micro-nozzle 27 to drive the metal powder to overcome the resistance and pulse forward continuously; the piezoelectric ceramic of the piezoelectric driver 26 is controlled by a computer.

[0028] According to the laser precision micro-forming powder feeding method of the present invention, according to the different components, uniformity, sphericity and powder forming methods of the metal powder, the speckle diameter of the powder sprayed by the quartz micro-nozzle 27 can be controll...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com