3D printing method of metal ceramic functional gradient part in alternating magnetic field

A cermet and alternating magnetic field technology, which is applied in the direction of improving energy efficiency, process efficiency, additive manufacturing, etc., and can solve problems such as the inability to prepare intermetallic or cermet gradient parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific example 1

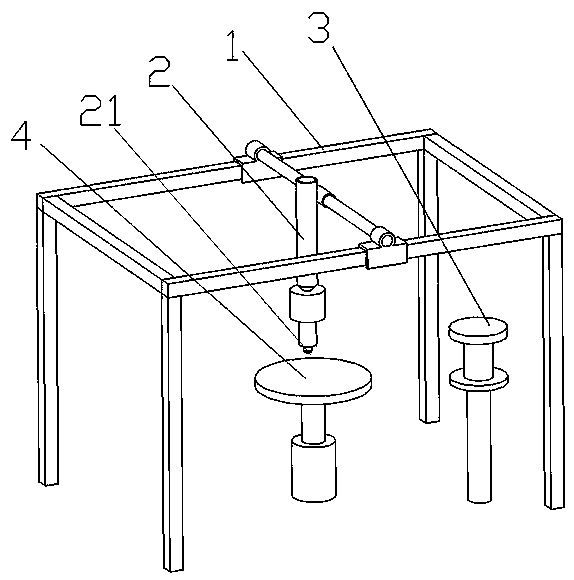

[0051] see figure 1 , Figure 5 , Image 6 with Figure 7 As shown, one of the present invention is a 3D printing method of cermet functionally graded parts in an alternating magnetic field, and the steps of the method are as follows:

[0052] One: The preparation of the mixed slurry, the cermet powder and the polymer binder are evenly mixed and then heated, the mixed slurry melts at 170°C and solidifies rapidly at room temperature;

[0053] The composition and mass percent of the mixed slurry are as follows:

[0054] 60% metal ceramic powder, 40% polymer binder;

[0055] The composition and mass percentage of the cermet powder are as follows:

[0056] Metal powder 33%, ceramic powder 67%;

[0057] The metal powder: 1-90 μm, with a median particle size of 40 μm;

[0058] The metal powder material is Cu;

[0059] The ceramic powder: 1-90 μm, with a median particle size of 40 μm;

[0060] The ceramic powder material is Al2O3;

[0061] The composition and mass percentag...

specific example 2

[0068] see figure 1 , Figure 5 , Image 6 with Figure 7 As shown, one of the present invention is a 3D printing method of cermet functionally graded parts in an alternating magnetic field, and the steps of the method are as follows:

[0069] One: The preparation of the mixed slurry, the cermet powder and the polymer binder are evenly mixed and then heated. The metal slurry melts at 200 ° C and solidifies rapidly at room temperature;

[0070] The composition and mass percent of the mixed slurry are as follows:

[0071] Metal-ceramic powder 63%, polymer binder 37%;

[0072] The composition and mass percentage of the cermet powder are as follows:

[0073] Metal powder 35%, ceramic powder 65%;

[0074] The metal powder: 1-90 μm, with a median particle size of 40 μm;

[0075] The metal powder material is Fe;

[0076] The ceramic powder: 1-90 μm, with a median particle size of 40 μm;

[0077] The ceramic powder material is SiC;

[0078] The composition and mass percentag...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com