W/Cu functionally gradient material and preparation method thereof

A technology of functionally graded materials and gradient materials, which is applied in the field of additive manufacturing technology and powder metallurgy, can solve problems such as functional defects, difficulty in meeting design requirements of materials, and difficulty in accurately controlling the pore distribution of W skeleton, etc., achieving short processing cycle and high efficiency , high precision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

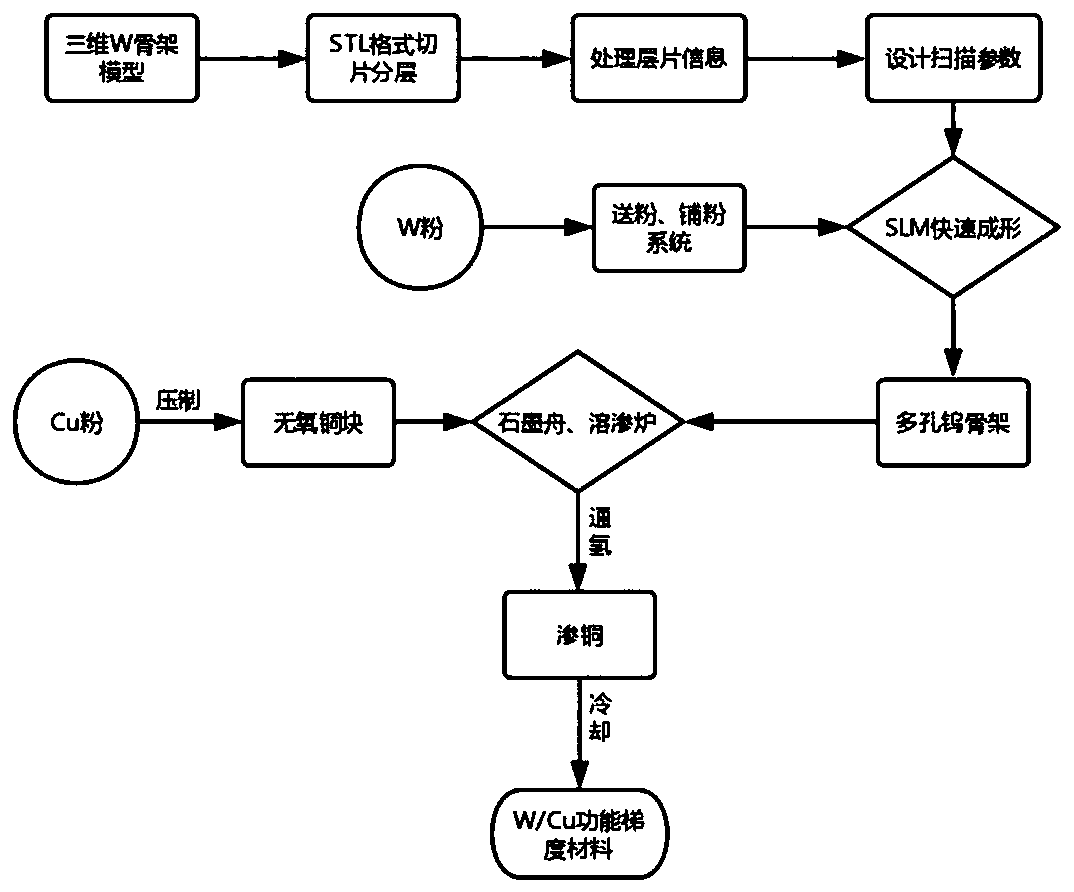

[0050] Please refer to figure 1 , the embodiment of the present invention provides a preparation method of W / Cu functionally graded material based on 3D printing, comprising the following steps:

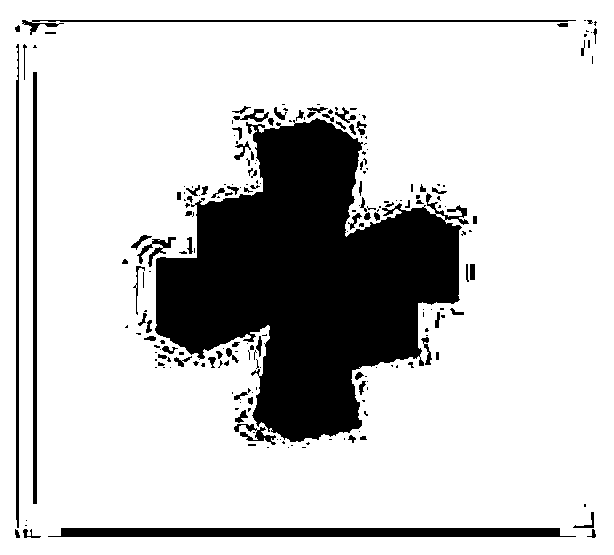

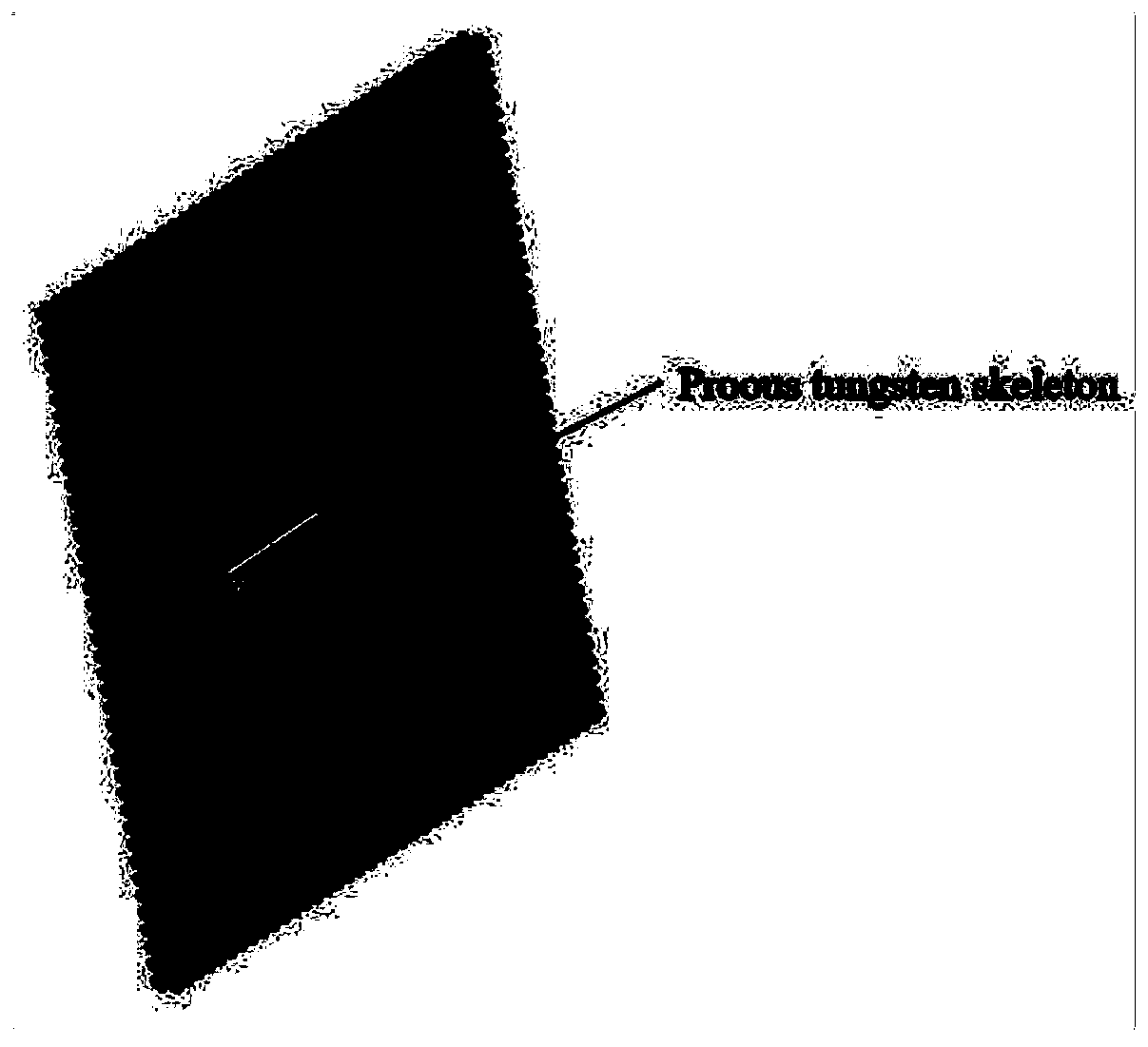

[0051] 1) Create a 3D model of the porous tungsten skeleton through magics20.03, slice and layer the 3D model of the porous tungsten skeleton. The size of the 3D model of the single-layer porous tungsten skeleton is 20mm*20mm*1mm. cross, figure 2 It is a schematic diagram of a three-dimensional cross unit body of a single layer of a porous tungsten skeleton three-dimensional model in an embodiment of the present invention, image 3 It is a schematic diagram of the single-layer structure of the three-dimensional model of the porous tungsten skeleton in the embodiment of the present invention.

[0052] Merge the single layers established one by one into a three-layer gradient tungsten skeleton 3D model, and import the data into the 3D printing device; in the established tungsten ske...

Embodiment 2

[0061] The embodiment of the present invention provides a method for preparing a W / Cu functionally graded material based on 3D printing, comprising the following steps:

[0062] 1) Create a 3D model of the porous tungsten skeleton through magics20.03, slice and layer the 3D model of the porous tungsten skeleton. The size of the 3D model of the single-layer porous tungsten skeleton is 20mm*20mm*1mm. cross.

[0063] Merge the established single layers one by one into a four-layer gradient tungsten skeleton three-dimensional model, and import the data into the 3D printing device; in the established three-dimensional tungsten skeleton model, the porosity ratio is controlled by changing the size of the three-dimensional cross unit, so as to ensure that the permeability Gradient change of W / Cu mass after copper.

[0064] Weigh tungsten powder, the tungsten powder is spherical or nearly spherical, the average particle size is 15 μm ~ 40 μm, and the purity is 99.9%. When 3D printing,...

Embodiment 3

[0072] The embodiment of the present invention provides a method for preparing a W / Cu functionally graded material based on 3D printing, comprising the following steps:

[0073] 1) Create a 3D model of the porous tungsten skeleton through magics20.03, slice and layer the 3D model of the porous tungsten skeleton. The size of the 3D model of the single-layer porous tungsten skeleton is 20mm*20mm*1mm. cross.

[0074] Merge the single layers built one by one into a five-layer gradient tungsten skeleton three-dimensional model, and import the data into the 3D printing device; in the established three-dimensional tungsten skeleton model, the porosity ratio is controlled by changing the size of the three-dimensional cross unit, so as to ensure Gradient change of W / Cu mass after copper.

[0075] Weigh tungsten powder, the tungsten powder is spherical or nearly spherical, the average particle size is 15 μm ~ 40 μm, and the purity is 99.9%. When 3D printing, first set the forming param...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com