Method for preparing functional gradient material by adopting doctor-blade casting process

A technology of functionally graded materials and tape casting, which is applied in the field of preparing functionally graded materials, can solve problems such as changing raw material components or process parameters, lack of preparation methods, and limiting the development of functionally graded materials, and achieves the effects of simplifying procedures and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

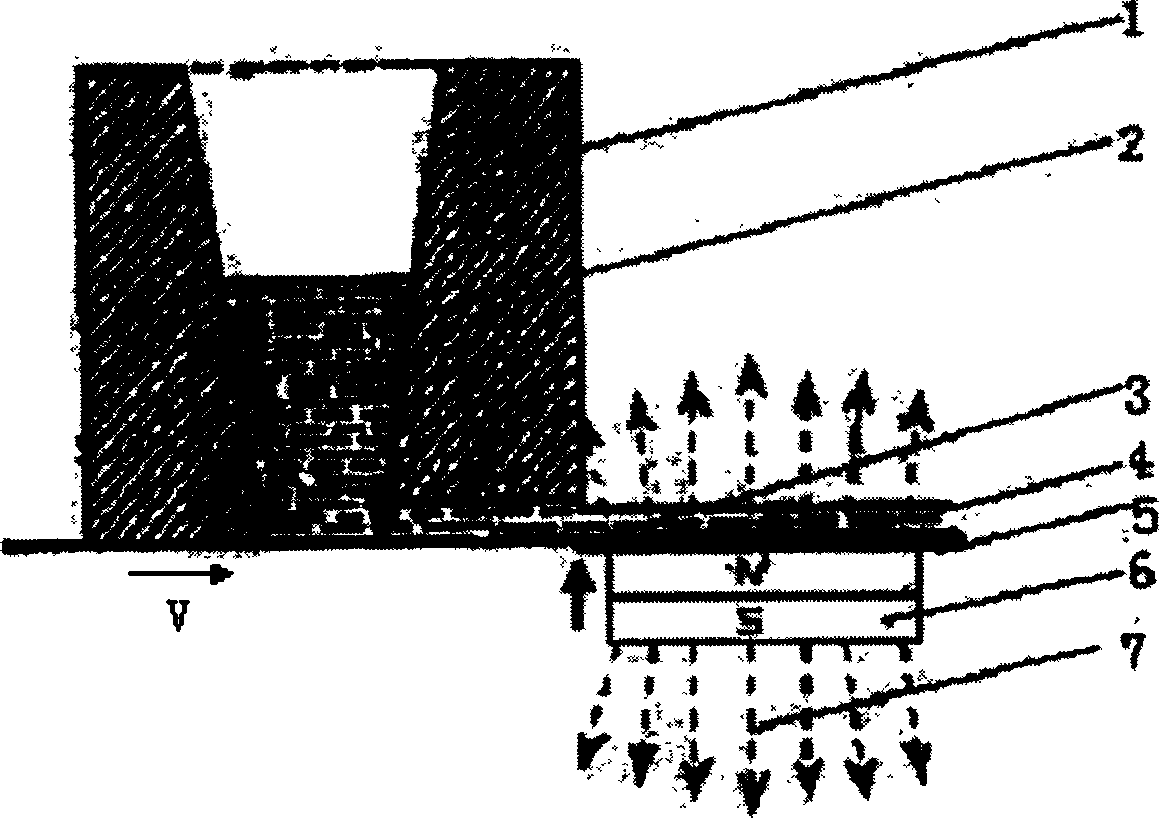

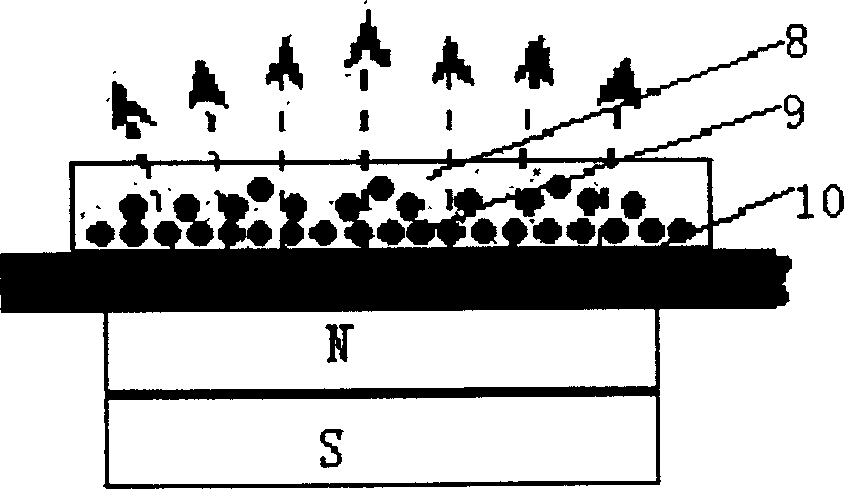

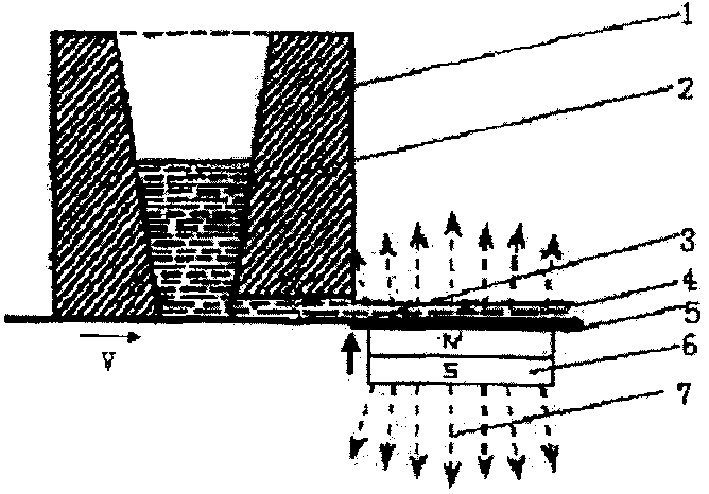

Method used

Image

Examples

Embodiment 1

[0031] 1) Nickel powder with an average particle size of 20 μm and Al with an average particle size of 9 μm 2 o 3 The powder is composed of mixed powder in a ratio of 1:2, and a mixed solvent is added. The mixed solvent is trichlorethylene and ethanol mixed at a ratio of 1:1, and the dispersant triolein is added. The above raw materials are mixed and ball milled for 30 hours, and then added into the bonding Agent PVB, plasticizer glycerin and dioctyl phthalate. The binder is 30% of the mass fraction of the slurry, and the binder / plasticizer weight ratio is 0.6. Then ball mill the slurry for 36 hours, disperse it by ultrasonic wave for 5 minutes, and degas it under vacuum to remove air bubbles to make a uniformly dispersed slurry. The solvent volume fraction in this slurry is 50% of the slurry, the dispersant is 3% of the slurry volume fraction, the slurry viscosity is 60mPa·s, the pH value is 5.7, and the temperature is 32°C.

[0032] 2) The ambient temperature during casti...

Embodiment 2

[0036] 1) Select Co powder with an average particle size of 14 μm and ZrO with an average particle size of 12.2 μm 2 The powder is mixed in a ratio of 1:2 to form a mixed powder, and a mixed solvent is added. The mixed solvent is methyl ethyl ketone and ethanol, mixed according to 1:1, and the dispersant triethanolamine is added, the above raw materials are mixed and ball milled for 30 hours, and then the binder PVB, the plasticizer polyethylene glycol (PEC) and phthalic acid (PHT) are added . The binder is 30% of the mass fraction of the slurry, and the binder / plasticizer weight ratio is 0.8. Then ball mill for 36 hours, disperse with ultrasonic waves for 3 minutes, and degas in vacuum to remove air bubbles to make a uniformly dispersed slurry. The solvent volume fraction in this slurry is 60% of the slurry, the dispersant is 2% of the slurry volume fraction, the slurry viscosity is 40mPa·s, the pH value is 6.2, and the temperature is 30°C.

[0037] 2) The ambient temperat...

Embodiment 3

[0041] 1) Select Co powder with an average particle size of 16 μm and TiC powder with an average particle size of 28 μm, form a mixed powder in a ratio of 1:1, and add a mixed solvent. The mixed solvent is trichlorethylene / ethanol, mixed according to 1:1, and the dispersant triethanolamine is added. The above raw materials were mixed and ball milled for 30 hours, and then the binder PVB and the plasticizer glycerin were added. The binder is 20% of the mass fraction of the slurry, the binder / plasticizer weight ratio is 0.8, and ball milled for 30 hours. Disperse with ultrasound for 5 min. After vacuum degassing and air bubble removal, a uniformly dispersed slurry is made. The solvent volume fraction in this slurry is 50% of the slurry, the dispersant is 2% of the slurry volume fraction, the slurry viscosity is 80mPa·s, the pH value is 7, and the temperature is 30°C.

[0042] 2) The ambient temperature during casting is 23°C, the casting speed used is 0.8cm / s, the height of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com