Powder conveying and paving mechanism linked with power bed

A transmission mechanism and powder spreading technology, which is applied in the field of additive manufacturing, can solve problems such as the inability to prepare gradient materials, the inability to realize follow-up powder feeding, etc., and achieve the effect of reducing volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

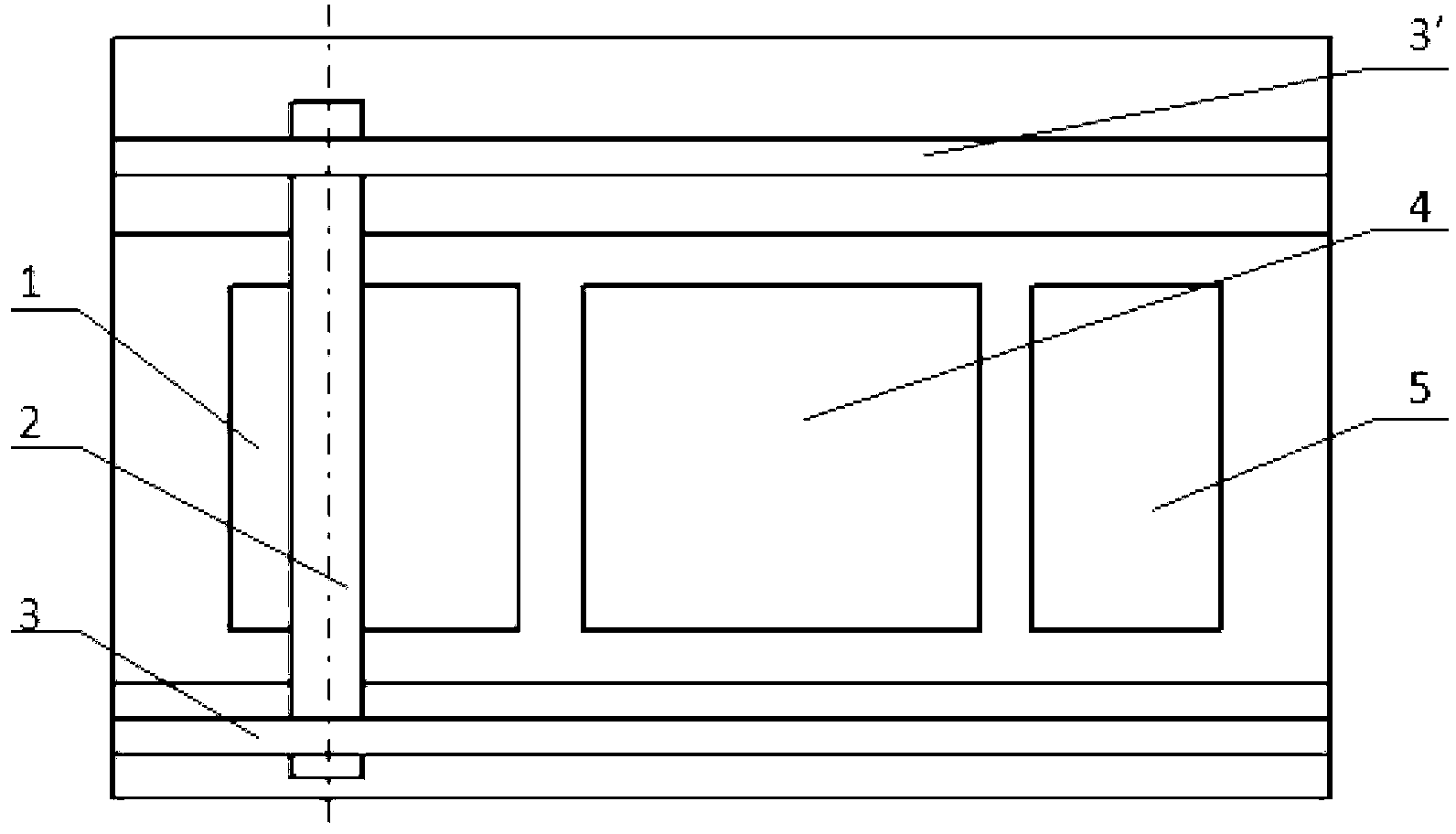

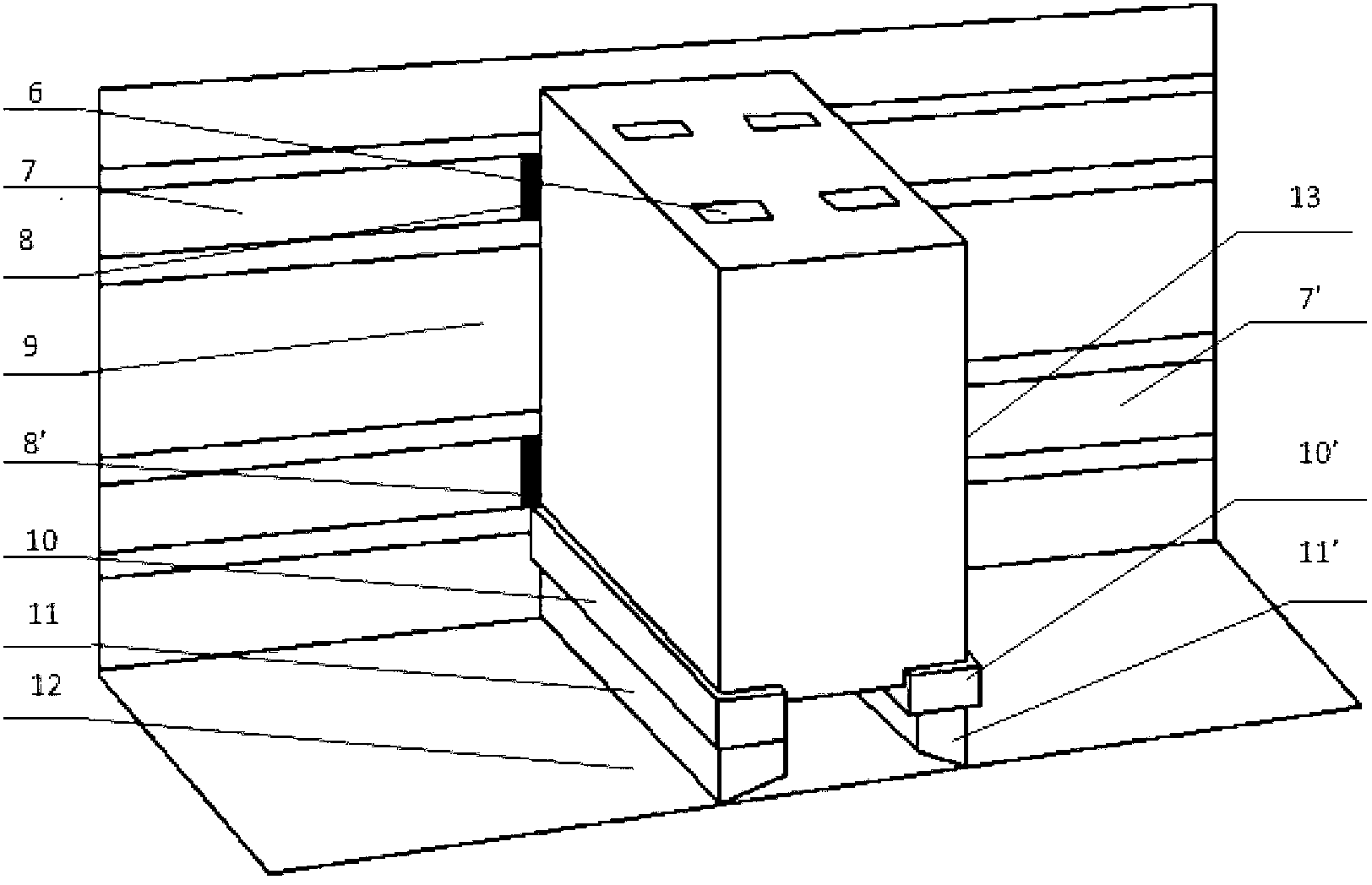

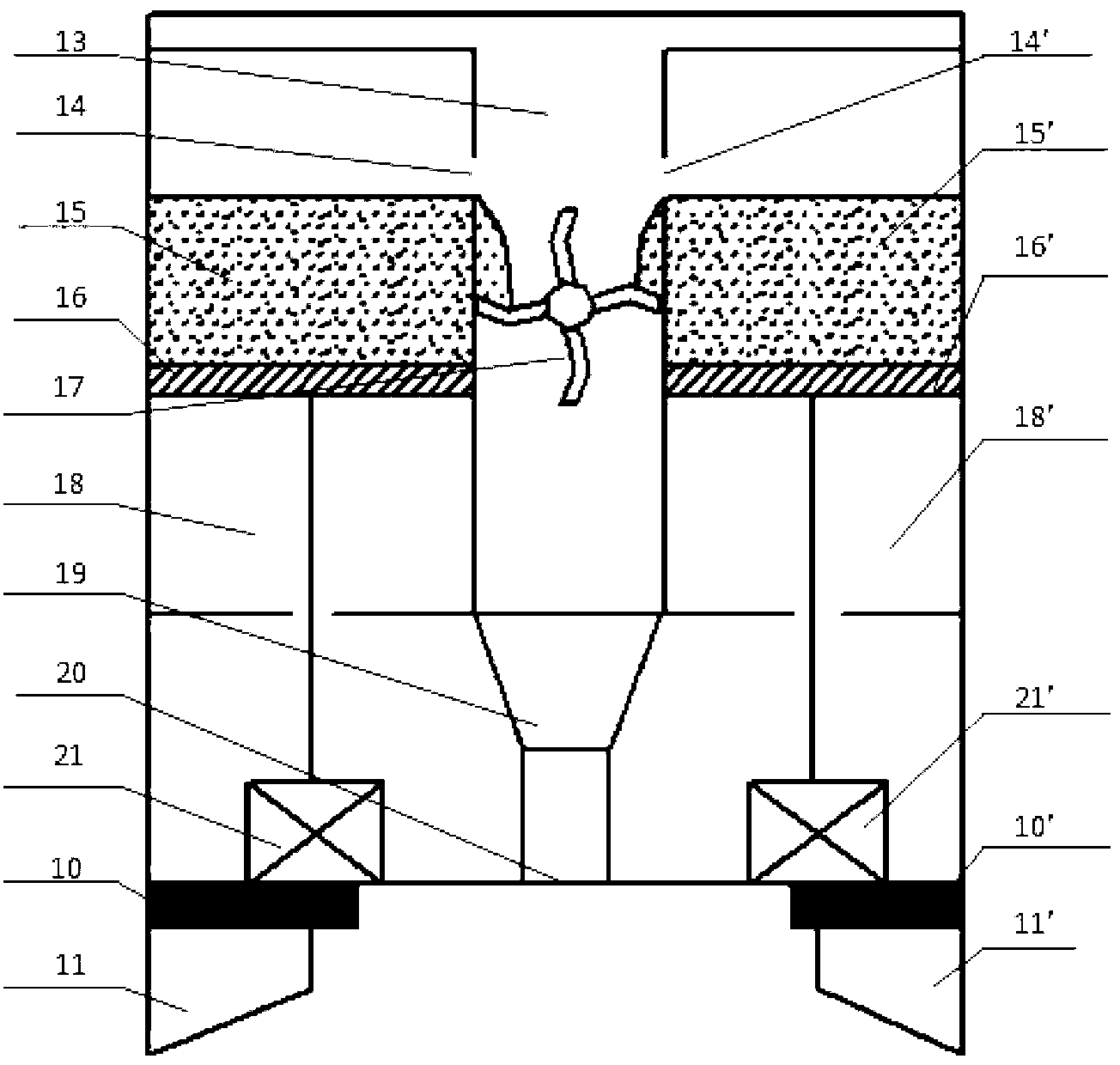

[0037] by image 3 Shown is an example of forming a gradient material containing two powders. Take the SLM process as an example. First, use UG and other modeling software to draw the parts, convert them into STL format, and import them into the PowerRP software of the rapid prototyping system. The software reads the part information, slices and layers the 3D model of the part. Fix the base plate on the working cylinder and level the base plate. In the hoppers 18, 18', a sufficient amount of A and two powders of B are respectively loaded in advance. After the preparatory processes such as vacuuming and filling the protective gas in the forming cavity are completed, the powder feeding action starts. According to the composition ratio of two different materials, the corresponding motor 21, 21' speed of the control piston 16, 16' is set. When the A powder needs to be formed as the base material in the initial state, the hopper piston 16' of the B powder can be used as the mot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com