Method for preparing magnesium alloy plate strip with grain size in symmetric gradient distribution along plate thickness direction

A technology of magnesium alloy plate and grain size, which is applied in the field of magnesium alloy processing, can solve the problems of poor ductility, achieve the effects of improving strength and ductility, reasonable process design, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

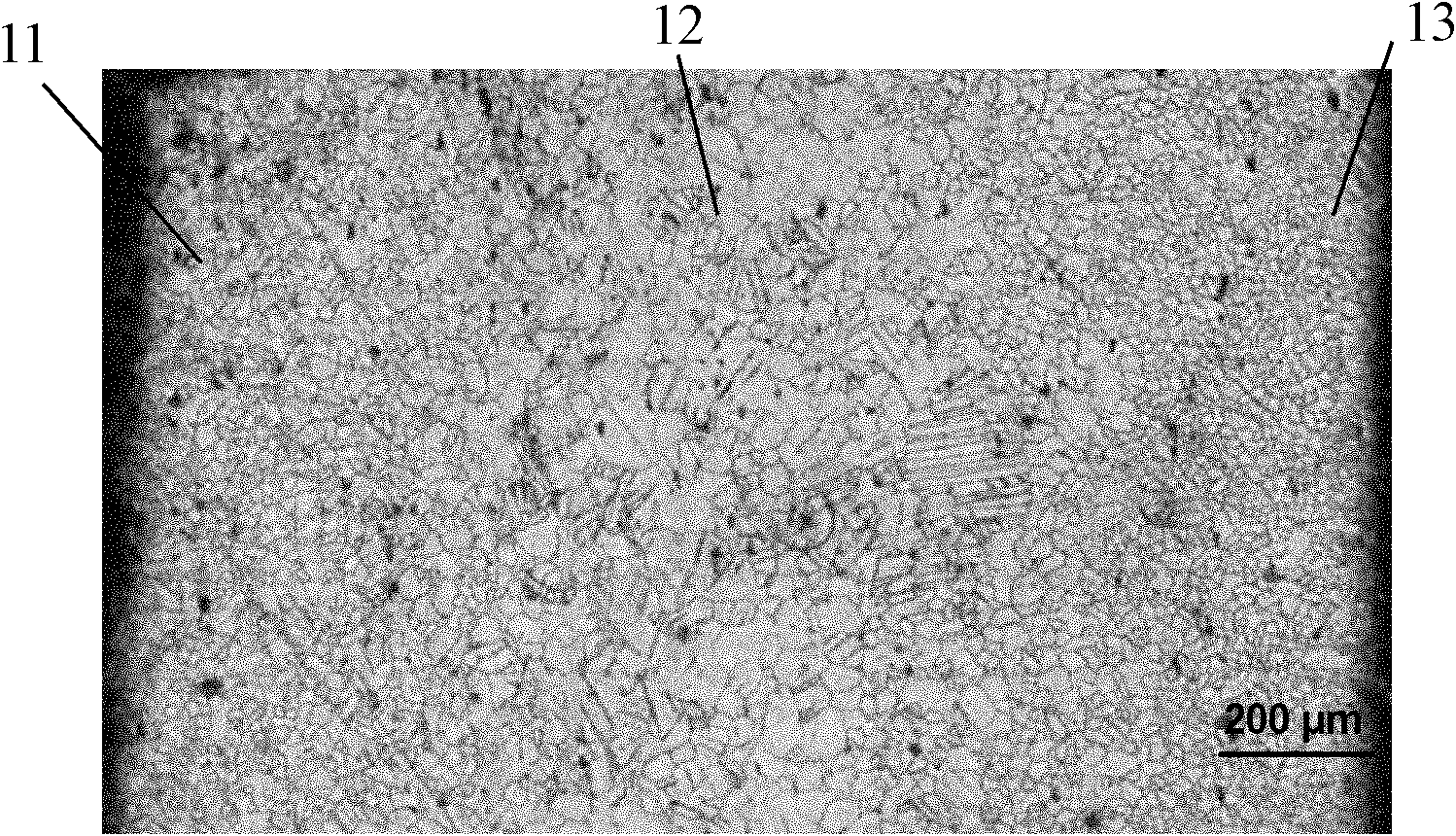

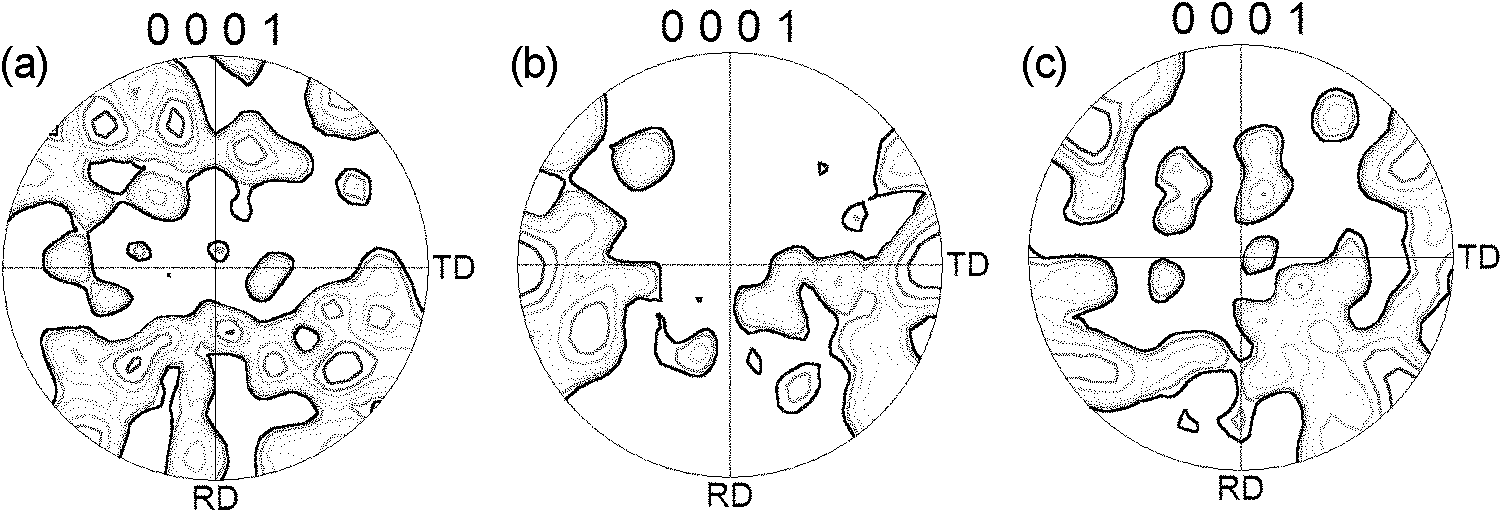

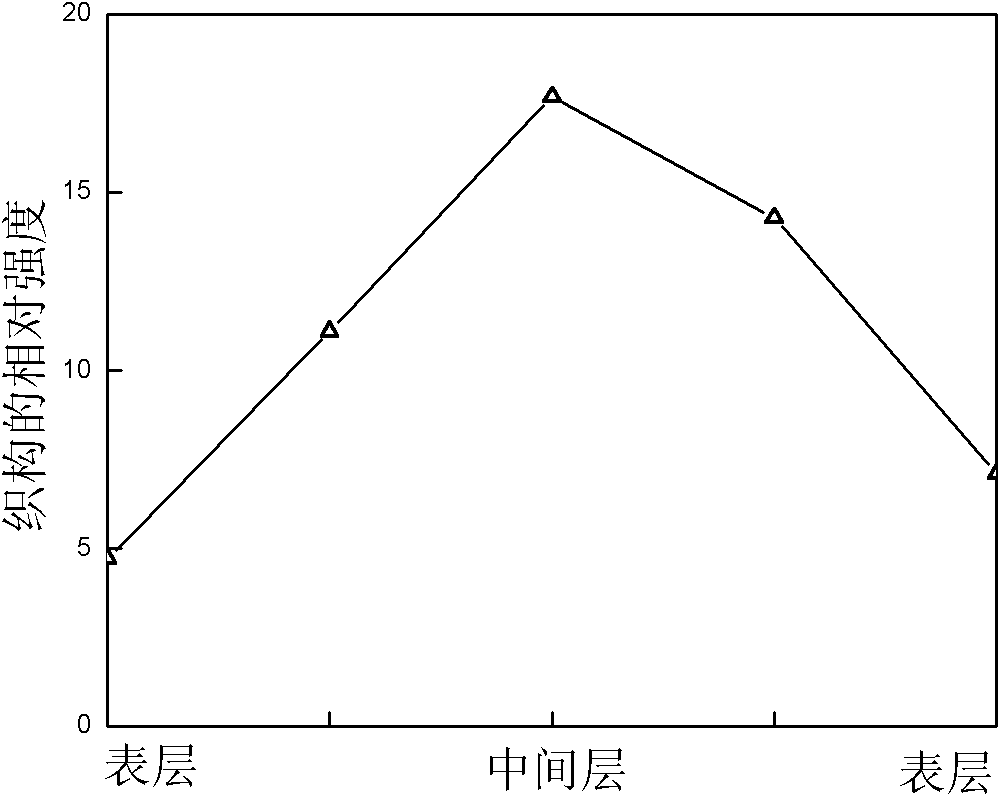

[0027] The AZ31 magnesium alloy was subjected to two-way repeated bending deformation with 3 rolls at 150°C, and the deformation amount in a single pass was 0.25. The size and texture strength are distributed in a gradient along the plate thickness direction, the surface grains are refined to 1 / 3 of the original, and the thickness of the fine-grained layer is about 0.4mm; the {0001} basal texture strength of the surface layer is weakened to only the middle About 1 / 4 of the layer.

Embodiment 2

[0029] The AZ31 magnesium alloy was subjected to two-way repeated bending deformation with 3 rolls at 250 °C, and the deformation amount in a single pass was 0.14. The size and texture strength also have a gradient distribution along the plate thickness direction, the surface grains are refined to 1 / 3 of the original, and the thickness of the fine-grained layer is about 0.3mm; the {0001} basal plane texture strength of the surface layer is only middle About 1 / 4 of the layer.

Embodiment 3

[0031] The AZ31 magnesium alloy was subjected to two-way repeated bending deformation with 4 rolls at room temperature. The deformation amount in a single pass was about 0.01. After 3 passes of deformation, it was recrystallized and annealed at 400°C for 10 minutes. Microstructure observation and texture analysis showed that the surface grains The size has grown substantially to more than 5 times its original size.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com