System and method for deeply treating tail water of sewage plant

A technology for advanced treatment and sewage treatment plants, applied in water/sewage treatment, biological water/sewage treatment, multi-stage water/sewage treatment, etc., can solve environmental secondary pollution and other problems, achieve high degree of automation, improve settlement performance, The effect of mature technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to facilitate those skilled in the art to understand and implement the present invention, the present invention will be described in further detail below in conjunction with the accompanying drawings. It should be understood that the implementation examples described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

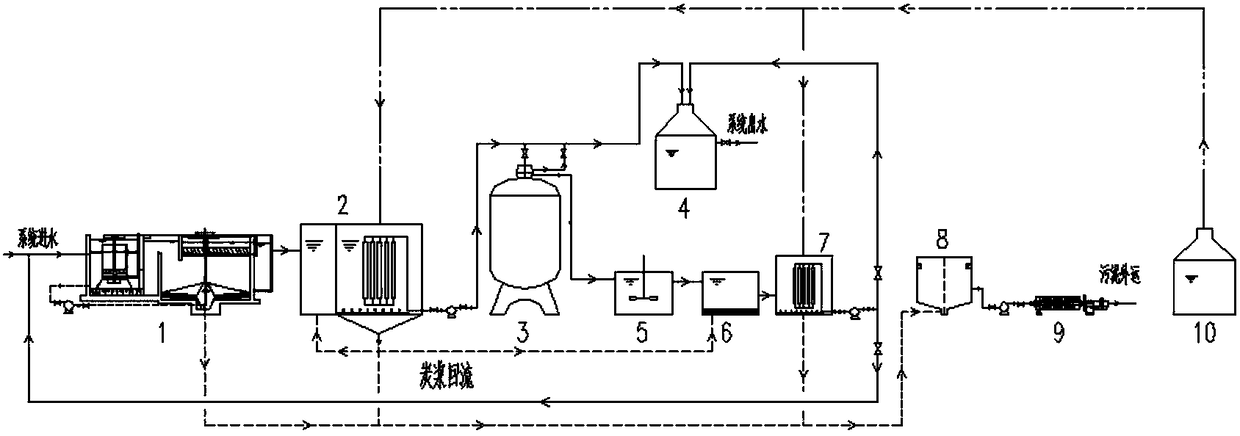

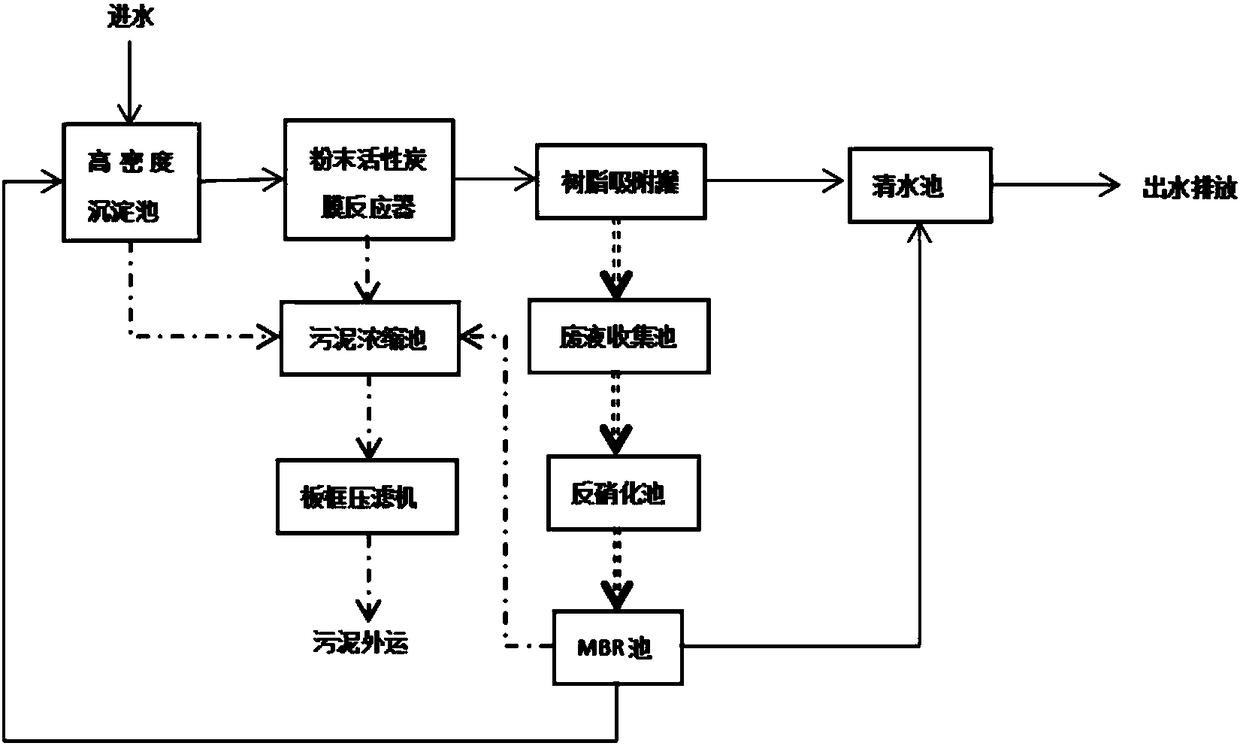

[0021] please see figure 1 A system for advanced treatment of tail water of a sewage plant provided by the present invention includes a high-density sedimentation tank 1, a powdered activated carbon membrane reactor 2, a resin adsorption tank 3, a clear water tank 4, a waste liquid collection tank 5, a denitrification tank 6, MBR pool 7, sludge concentration pool 8, plate and frame filter press 9, backwash pool 10, dosing system, electric control system;

[0022] The first grade A or grade B tail water of the municipal sewage treatment plant is used as the raw water, and the ra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| volume ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com