Recovery processing method of food waste

A kitchen waste, recycling and processing technology, applied in the direction of solid waste removal, etc., can solve the complex situation that cannot adapt to the irregularity of the discharge of kitchen waste, the high energy consumption of the solid waste hot air drying device, and the speed of mechanical and biochemical treatment. Slow and other problems, to achieve the effect of simple structure, low cost and fast processing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

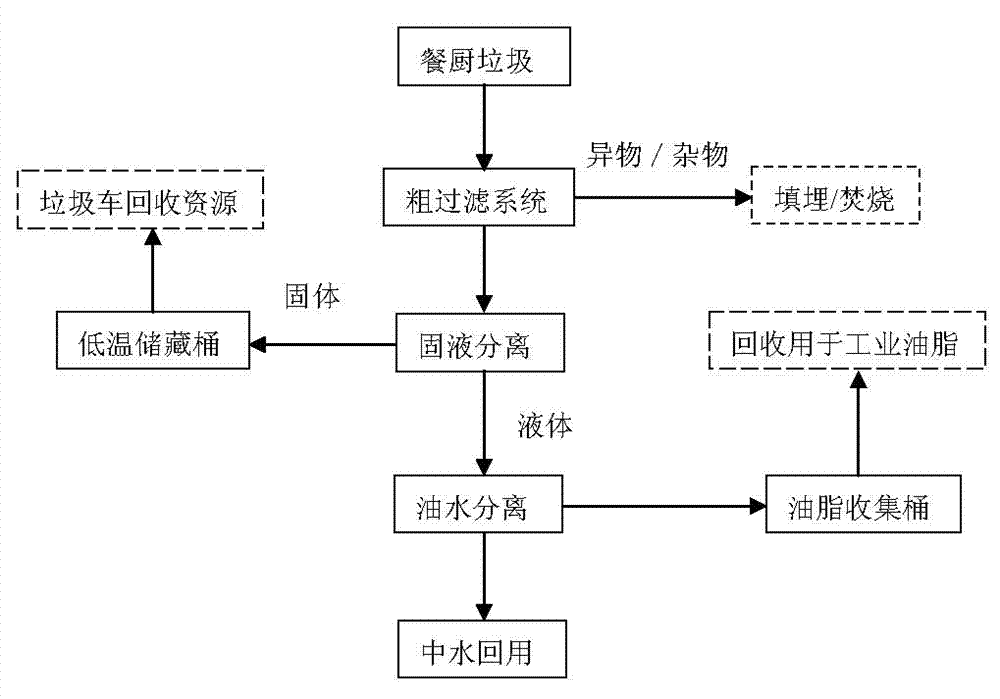

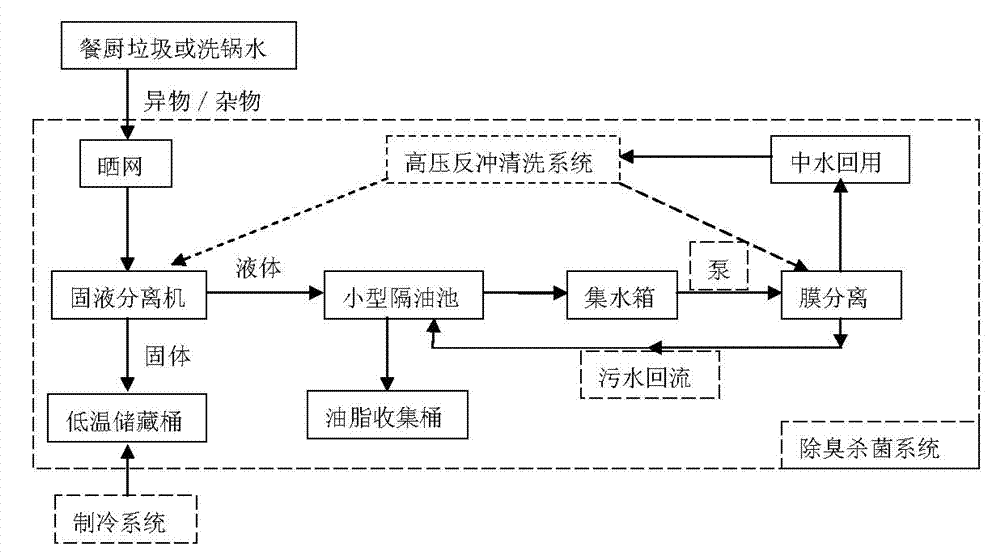

[0016] See figure 2 , a method for recycling food waste, the steps of which include: food waste or kitchen washing water, passing through a drying net, coarsely filtered food waste enters the integrated ultra-fine grid (aperture 0.5 mm), screw extrusion The automatic solid-liquid separation device of the conveyor and high-pressure backwashing system is used for separation. The separated solid waste is transported to a low-temperature storage barrel for storage (5°C), and the separated liquid waste is discharged into a small grease trap.

[0017] The small grease trap collects floating oil and enters the grease collection barrel. The water from the grease trap enters the water collection tank, and the water stored in the water collection tank is pumped into the membrane separation device. The sewage separated by the membrane flows back into the grease trap, and the separated clear water is reused as reclaimed water, which can be used as water for the high-pressure recoil syst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com