On-line coal quality laser detection and analysis system

An analysis system and laser detection technology, applied in the direction of material excitation analysis, test sample preparation, sampling device, etc., can solve the problems of low sampling preparation and detection efficiency, inability to achieve full element analysis, and inability to apply real-time online applications. Achieve the effect of full element analysis, fast detection speed and low maintenance cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to better understand the present invention, the present invention is described in detail below in conjunction with specific examples. It will, however, be evident that various changes and modifications can be made to the present invention without departing from the broader spirit and scope of the invention as defined in the appended claims. Therefore, the following examples have an illustrative rather than a limiting meaning.

[0032] Example:

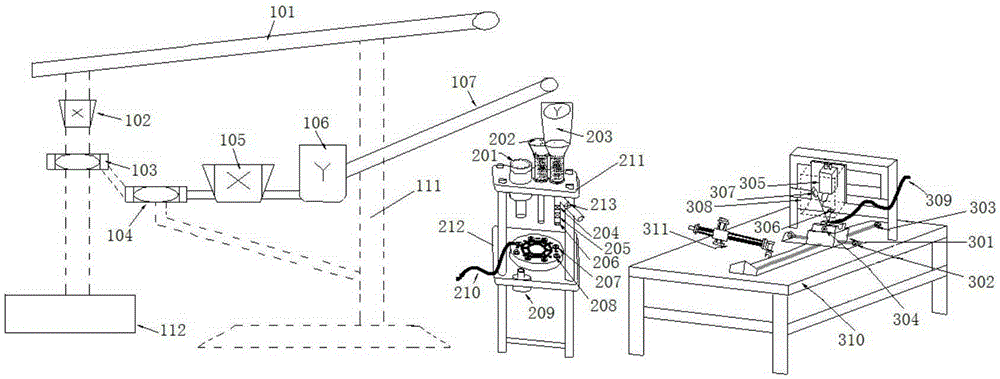

[0033] A laser online coal quality detection and analysis system, including a coal automatic sampling device, a coal continuous tableting sample preparation device, and a coal laser detection and analysis device connected sequentially through a control cable, a conveyor belt 107, and a manipulator 311; the coal automatic sampling device is connected in sequence Include the second shrinking machine 104, the second crusher 105 and the dry air device 106, the conveyor belt 107 in sequence, the first crusher 102 and the firs...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com