Ultra-low drainage vacuum preloading soft soil foundation treatment method

A technology of soft soil foundation and treatment method, which is applied in the fields of soil protection, infrastructure engineering, construction, etc., and can solve the problems such as the difficulty in ensuring the air tightness of the system, the lack of reinforcement of the bottom soil, and the small vacuum area. Achieve the effects of improving drainage preloading efficiency, enhancing reinforcement effect, and increasing vacuum action area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

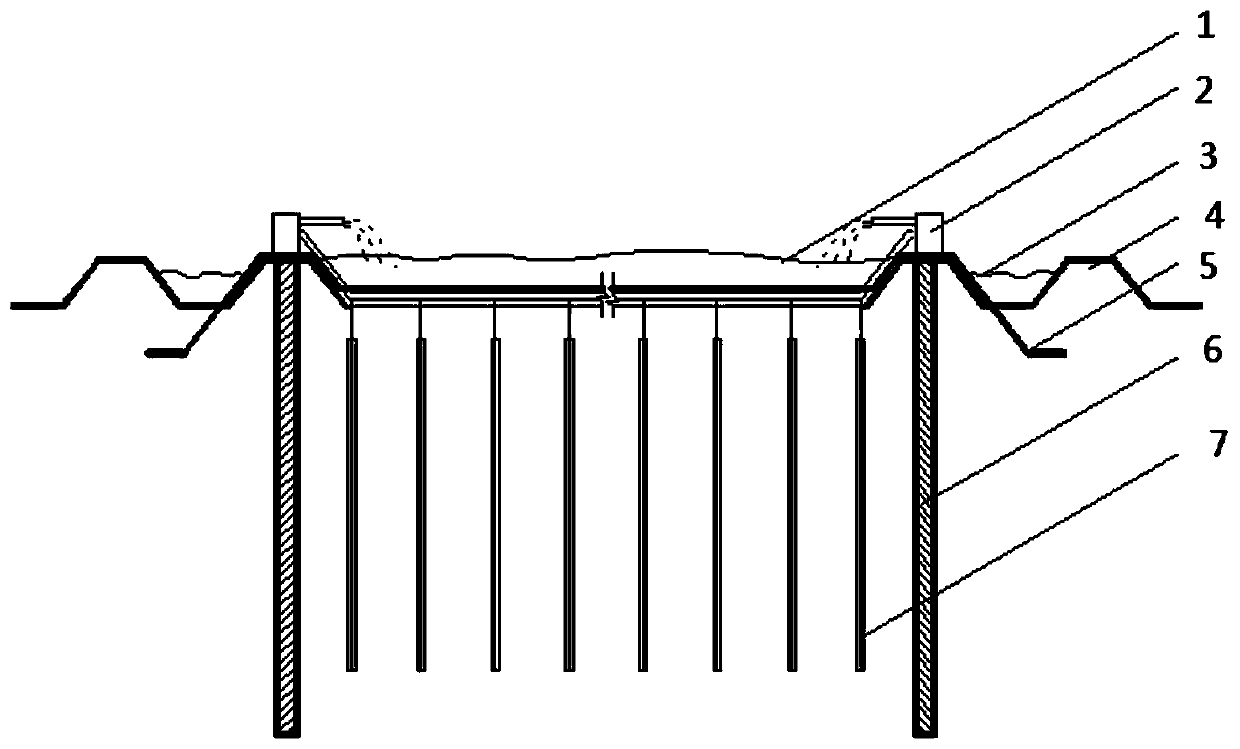

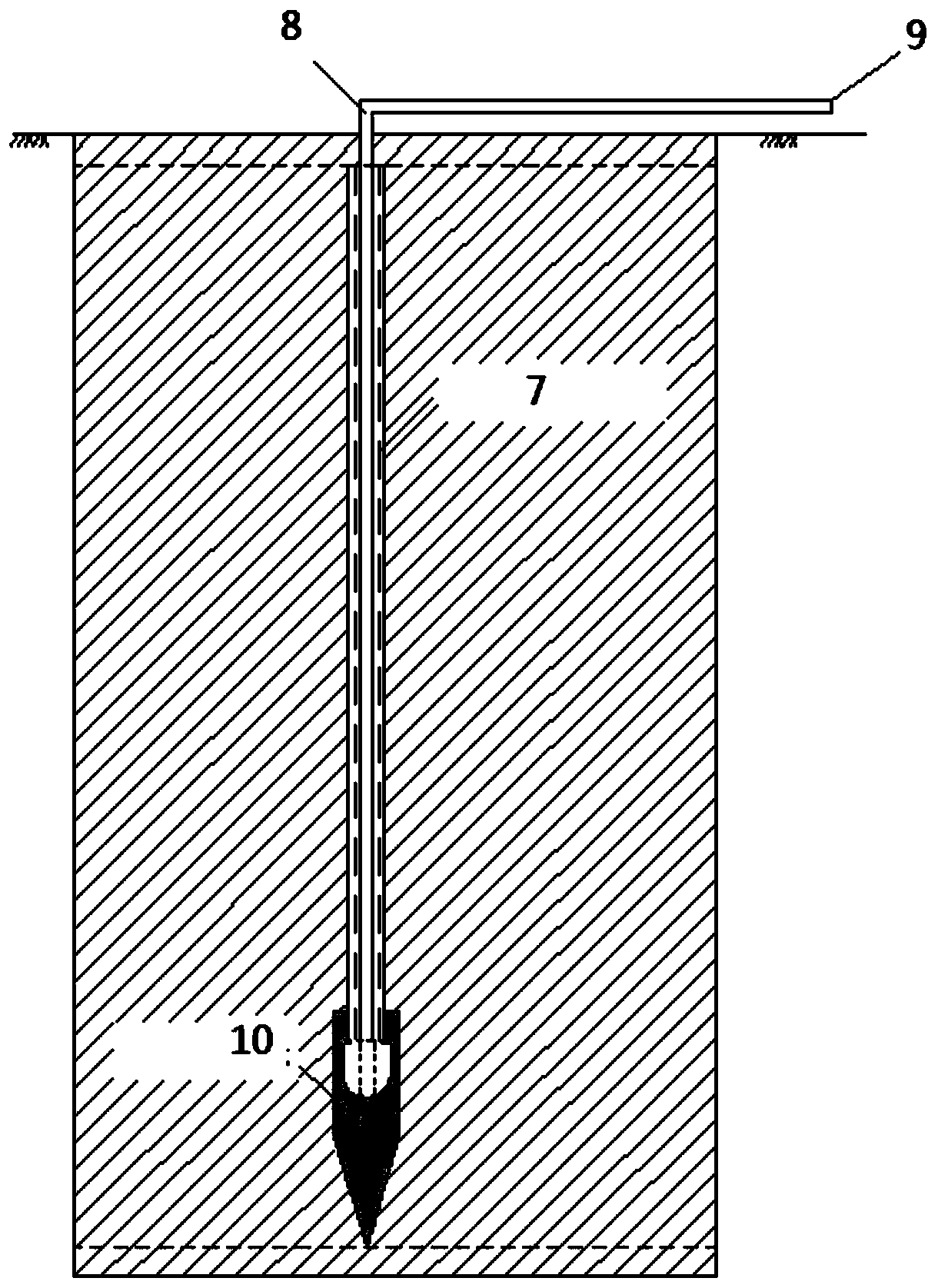

[0029] See attached Figure 1-2 , an ultra-low drainage vacuum preloading soft soil foundation treatment method, the specific construction process is as follows:

[0030] 1. Depending on the situation (the soil permeability coefficient in the reinforced area is greater than 10 -6 Order of magnitude or when there is a horizontal permeable layer) build a cofferdam around the reinforced area, the depth of the cofferdam should pass through the aquifer 2m, be greater than the thickness of the soil in the reinforced area and not less than 8m, to ensure the airtightness of the reinforced area;

[0031] 2. According to the power of the vacuum pump used, construct the soft foundation and treat the partitioned cofferdam;

[0032] 3. In the reinforced area, insert the low-level drainage body with the vacuum conduction sleeve to the design elevation of the reinforced area manually or mechanically, so that the main keel of the inserted low-level drainage body is 0.5-1m lower than the top ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com