Gas adsorption and desorption test apparatus

A technology of adsorption and desorption and test equipment, which is applied in the direction of analyzing materials and instruments, can solve the problems of non-existing isothermal adsorption, etc., and achieve the effects of reducing free space, improving experimental efficiency, and maintaining constant temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

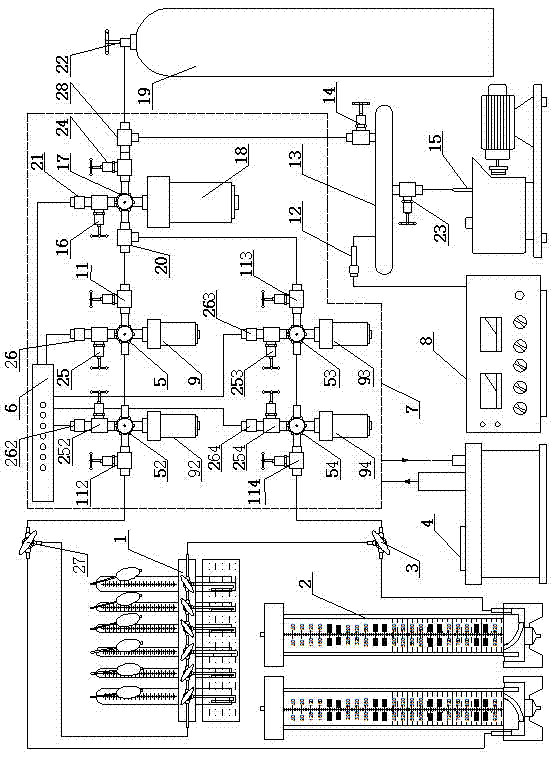

[0014] Such as figure 1 The shown gas adsorption and desorption test device includes an air charging system, a degassing system, a gas adsorption and desorption system and a temperature control system connected by pipelines.

[0015] The inflation system includes a high-pressure gas source 19 and a gas decompression valve 22 on the high-pressure gas source 19 . The high-pressure gas source 19 is a high-purity methane gas cylinder with a concentration of 99.999% and a pressure of 13.6Mpa produced by Beijing Hepu Gas Company. The gas pressure reducing valve 22 adjusts the gas to the pressure required for the experiment, so as to provide the gas adsorption and desorption system Provide constant pressure air source.

[0016] The degassing system includes a vacuum pump 15, a composite vacuum gauge 8, a vacuum gauge 12 and a vacuum piping system 13. A vacuum pumping control valve 14 is provided on the upper part of the vacuum piping system 13, and a control valve 23 is provided on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com